Floating plate device for deposition promotion and strengthening of sunken fascine mattress

A floating plate and sinking technology, applied in river regulation, climate change adaptation, etc., can solve the problems of scouring and carry away, high maintenance cost, and endangering the stability of the drainage body, so as to slow down the bottom water flow, with low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

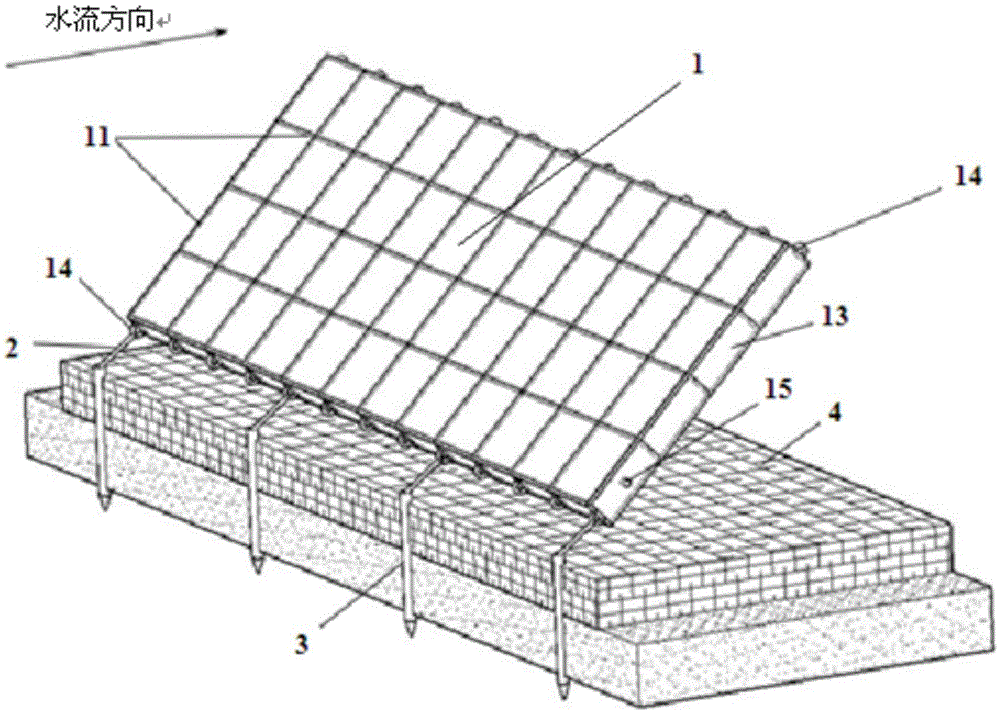

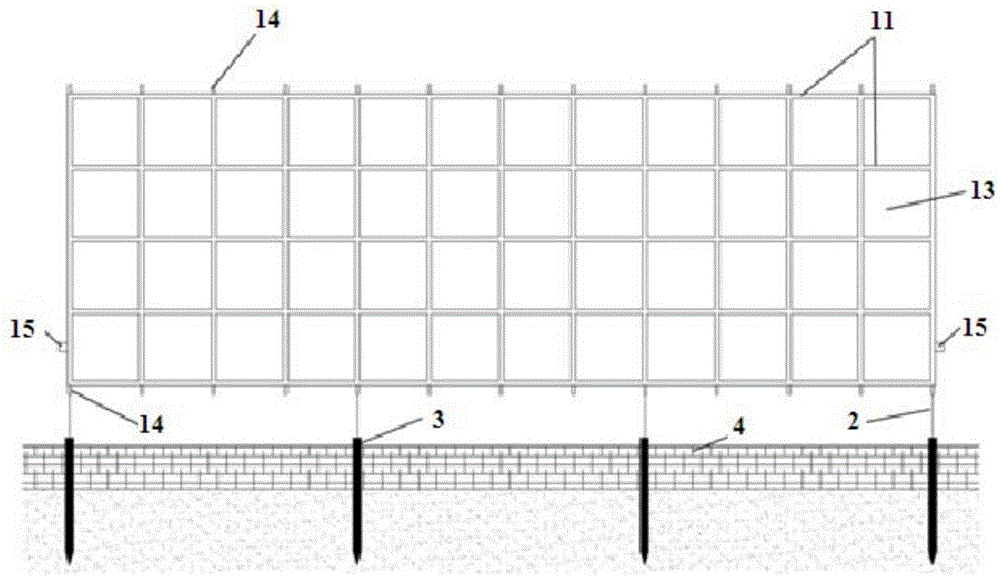

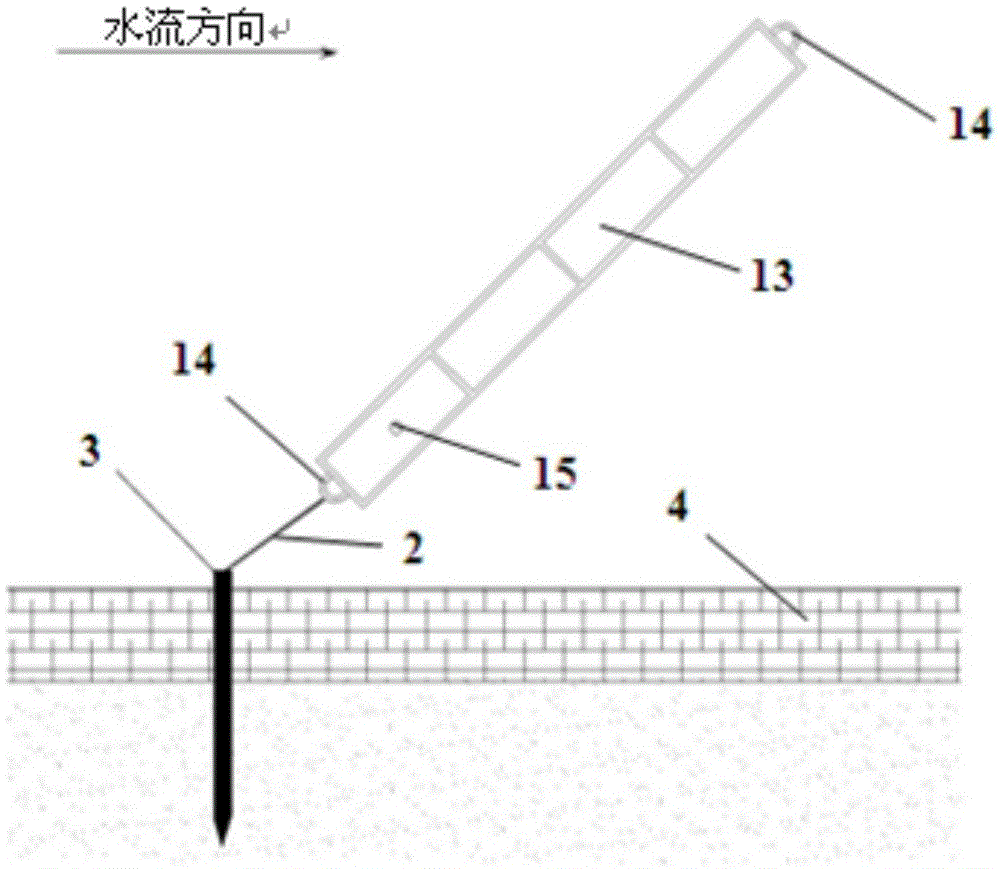

[0030] as follows Figure 1~4 As shown in the figure, a floating plate device for sinking, drainage and silting reinforcement includes a floating plate 1, a hanging rope 2 and an anchor pile 3. After the floating plate 1 is inflated, it becomes a rectangular plate with a length of 3m and a height of 1m. A slab external reinforcement strip 11 is arranged every 0.25m in the vertical and horizontal directions. Inside the buoyant plate 1 , there are evenly provided with inner reinforcing bands 12 to control the thickness of the inflated inflatable plate 13 . The upper and lower edges of the inflatable board 13 are evenly provided with a plurality of hanging rings 14, and the hanging rings 14 are directly connected to the outer ribs 11 of the board. An air injection port 15 is respectively arranged at the bottom of both sides of the inflatable board 13 .

[0031] The inflatable board 13 is made of a waterproof and weather-resistant flexible material. It is plate-shaped after infl...

Embodiment 2

[0036] Embodiment 2: Due to the silt-promoting function of the floating plate 1, the sand coming from the upstream will continuously silt on its upstream and downstream sides. However, when the thickness of the silt deposit reaches the silt limit of the floating plate 1, the bed scour and silt presents a dynamic balance, and the silt deposit stops, specifically as follows: Figure 6 and Figure 7 shown. At this point, if you wish to continue promoting silt, you can heighten the existing floating plate 1 . Since the floating plate 1 is a modularized standard component, it is easy to realize its heightened assembly requirements. The second-stage floating board is the heightened component. After the heightening, it will continue to play the function of promoting sedimentation, so that the sedimentation-promoting sediment reaches a new thickness. By analogy, through the installation of multi-stage floating boards, the designed Thickness of sediment-accelerated sedimentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com