A kind of preparation method of anode protection ring

An anode protection ring and electrolyte powder technology, applied in the field of aluminum electrolysis, can solve the problems of increasing the workload of carbon slag, increasing the energy consumption of electrolysis production, poor anti-oxidation performance, etc. The effect of high thermal shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

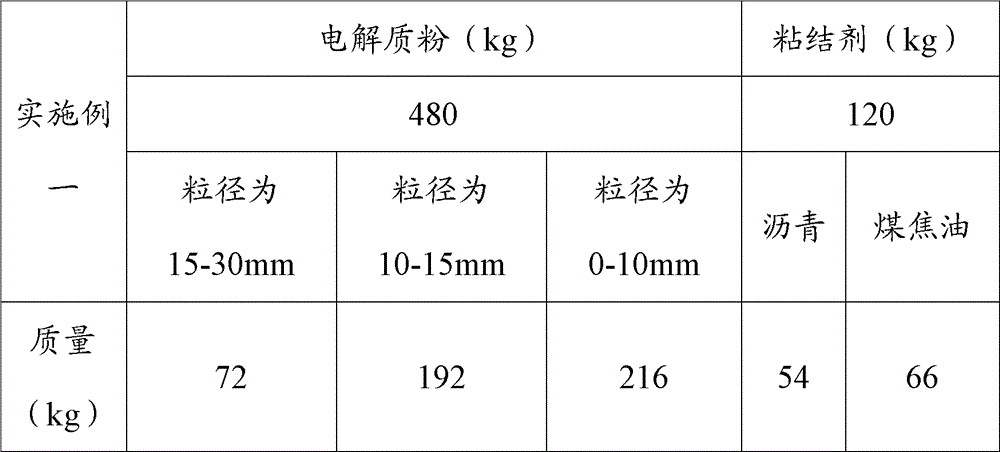

Embodiment 1

[0022] Crush the excess electrolyte with a crusher, grind the obtained powder with a ball mill for 1-3 hours, weigh 480kg of electrolyte powder (72g of electrolyte powder with a particle size greater than or equal to 15mm and less than or equal to 30mm, and a particle size of greater than or equal to 10mm and less than or equal to 15mm 192g of electrolyte powder, 216g of electrolyte powder with a particle size greater than 0mm and less than or equal to 10mm), 54kg of asphalt, and 66kg of coal tar; put the above raw materials into the kneading pot, raise the temperature to 85-130°C at the same time, and knead for 1 hour to form a slurry Then inject the slurry into the mold, put it into a hydraulic press for hydroforming, pressurize to 12-18MPa, and keep it for 15-35 seconds to obtain the anode protection ring. The mechanical strength of the prepared anode protection ring is much greater than that of ordinary carbon protection rings, and it has the advantages of abrasion resistan...

Embodiment 2

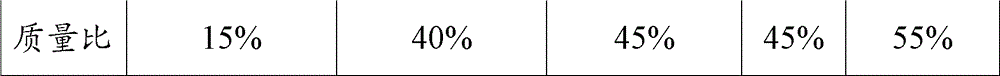

[0027] The steps of Embodiment 2 are the same as those of Embodiment 1, and the specific formula values are shown in the table below, wherein the mass of the binder is 20% of the mass of the electrolyte powder:

[0028]

Embodiment 3

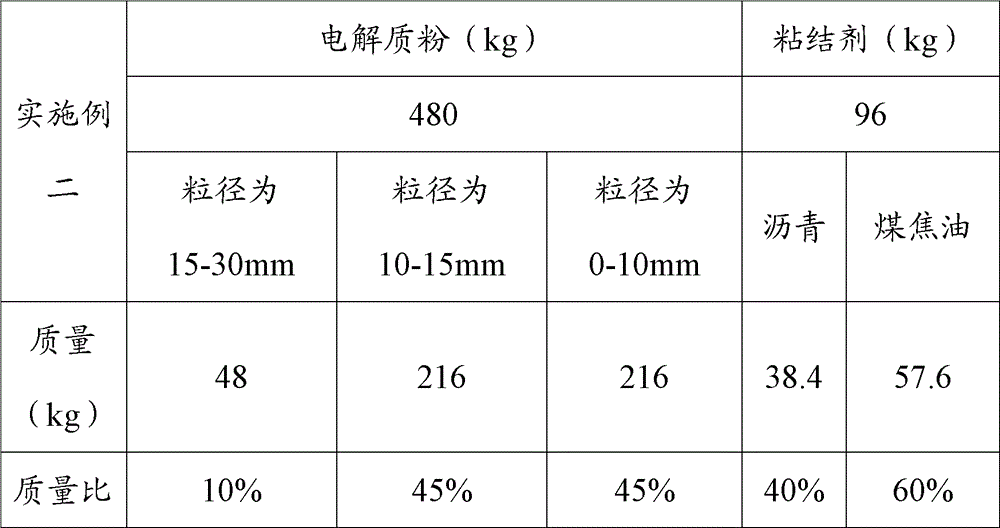

[0030] The steps of Embodiment 3 are the same as those of Embodiment 1, and the specific formula values are shown in the table below, wherein the mass of the binder is 10% of the mass of the electrolyte powder:

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com