Improved flat gate valve

A flat gate valve, improved technology, applied in sliding valve, valve details, valve device and other directions, can solve the problems of reduced valve sealing performance, shortened service life, increased valve operating torque, etc., to prolong service life and save spraying costs. , the effect of increasing the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

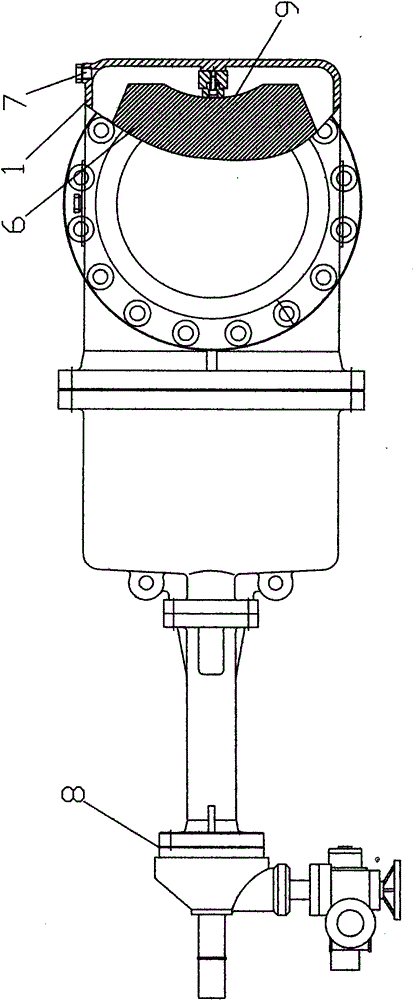

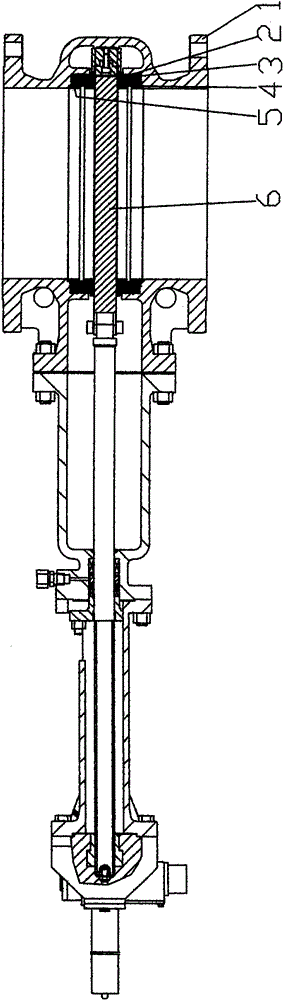

[0026] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

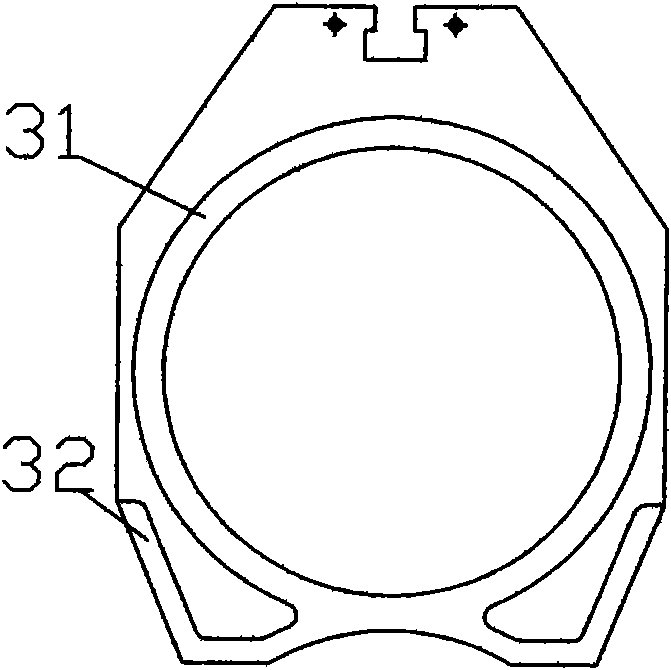

[0027] As shown in the accompanying drawings, the present invention includes a valve body, a valve seat, a valve stem, a gate plate, a valve cover and an operating mechanism. One end of the valve stem is connected to the gate, the other end is connected to the operating mechanism, the valve cover is fixedly connected to the valve body, the bottom of the valve body cavity is provided with a drain hole, the sealing area on both sides of the gate or / The tungsten carbide alloy protrusions are sprayed on the diversion area and the diversion area. The shape of the gate is automatically positioned (it mainly depends on the self-weight of the gate and the symmetrical structure of the gate lift groove) and the guide structure (the symmetrical structure on both sides of the gate as shown in the figure below) ), the bottom of the gate is provided with an arc-shaped groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com