Automatic Positioning Method of Drilling Rig

An automatic positioning and drilling rig technology, which is applied to drilling equipment and methods, automatic control systems for drilling, and earthwork drilling and mining, etc. It can solve problems such as large blast hole errors, poor roadway forming quality, and complicated procedures, and achieve high computing speed. Low requirements, fast computing speed, fast computing speed and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical problem to be solved by the present invention is to provide an accurate, fast and applicable calculation algorithm for the automatic positioning and drilling of the drilling rig.

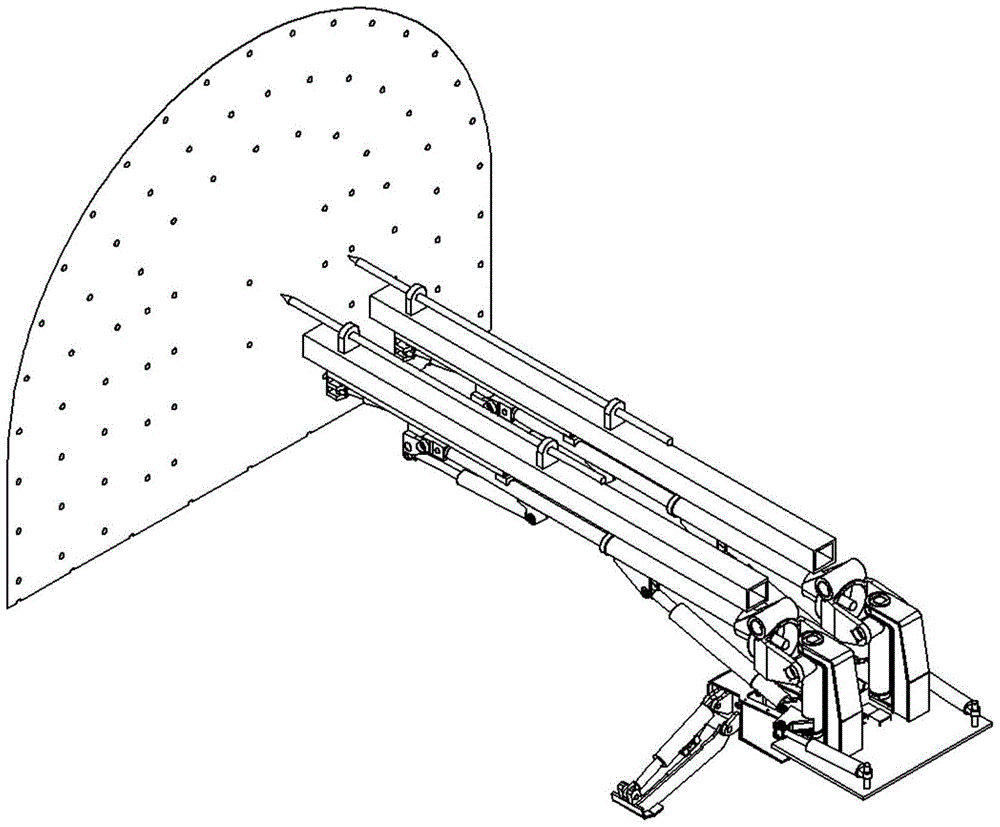

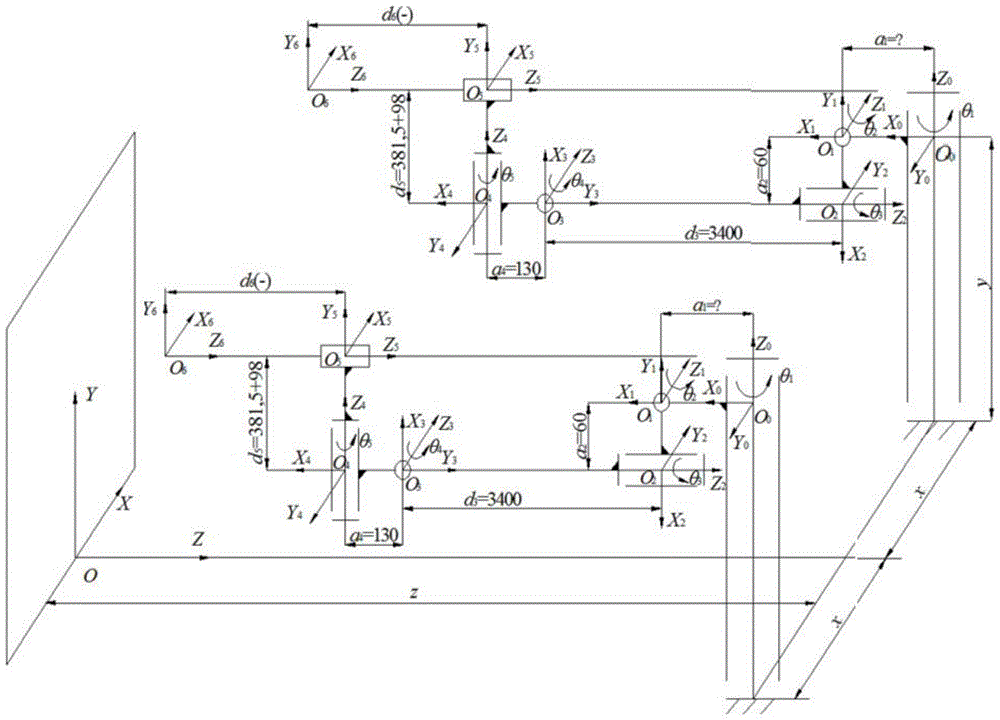

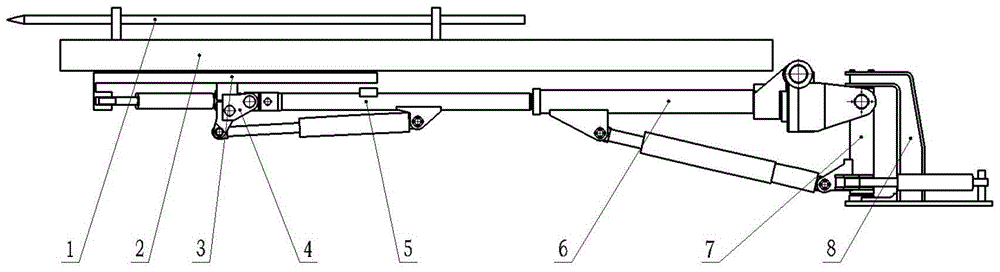

[0039] The operation method of the automatic positioning system of the drilling rig is based on the structure of the drilling rig. The main working mechanism of the drilling rig is the left and right drill arms, which are composed of a shaft sleeve 7, a drill boom frame 6, a branch pipe 5, a bracket 4, a directional slide 3, a slide frame 2 and drill rod 1, and the left and right drill arms are hinged on the frame 8 of the drilling car through the bushing 7, the bushing 7 is vertically arranged on the frame 8, when the bushing 7 rotates around its axis, Whole drilling arm swings left and right with respect to frame 8, as Figure 4a As shown, the present invention sets this action as the first action (that is, the first degree of freedom). The diameter direction of the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com