A pressurized high-level fuel tank with small oil supply pressure loss

A high-level fuel tank and pressure technology, applied in the direction of fuel supply tank device, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve problems such as increased viscosity, increased construction cost, and outflow of lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

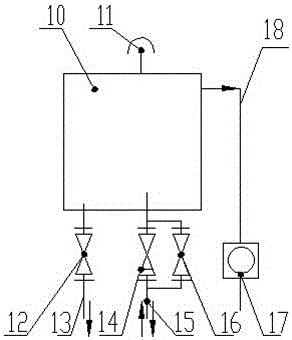

[0038] Such as Figure 4 and 5 As shown, the present invention provides a pressurized high-level fuel tank with a small oil supply pressure loss, including a tank body 10, the bottom of the tank body 10 is provided with a drain pipe 13 and a working oil pipe 15, and the drain pipe 13 is provided with The blowdown valve 12 is characterized in that the working oil pipe 15 is provided with an on-off control valve 5, the top of the box 10 is provided with a connecting pipe 1, and the connecting pipe 1 is provided with a throttling orifice group 2 for throttling The orifice plate group 2 is connected with a pre-pressurized air filter 3 through an overflow pipe 4. An overflow port 4-1 is provided on the middle side of the overflow pipe 4, and an oil return pipe 18 is connected to the overflow port 4-1. The oil return pipe 18 is provided with an oil return peek port 17 .

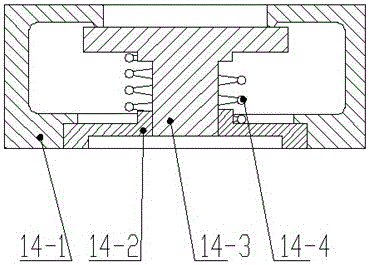

[0039] In this embodiment, the arrangement of the throttling orifice group 2 and the pre-pressurized air filte...

Embodiment 2

[0042] Such as Figures 4 to 6 As shown, the present invention provides a pressurized high-level fuel tank with a small oil supply pressure loss, including a tank body 10, the bottom of the tank body 10 is provided with a drain pipe 13 and a working oil pipe 15, and the drain pipe 13 is provided with The blowdown valve 12 is characterized in that the working oil pipe 15 is provided with an on-off control valve 5, the top of the box 10 is provided with a connecting pipe 1, and the connecting pipe 1 is provided with a throttling orifice group 2 for throttling The orifice plate group 2 is connected with a pre-pressurized air filter 3 through an overflow pipe 4. An overflow port 4-1 is provided on the middle side of the overflow pipe 4, and an oil return pipe 18 is connected to the overflow port 4-1. The oil return pipe 18 is provided with an oil return peek port 17 .

[0043] The throttle orifice group 2 includes an upper orifice 2-1 and a lower orifice 2-3, and a channel pipe 2...

Embodiment 3

[0045] Such as Figures 4 to 8 As shown, the present invention provides a pressurized high-level fuel tank with a small oil supply pressure loss, including a tank body 10, the bottom of the tank body 10 is provided with a drain pipe 13 and a working oil pipe 15, and the drain pipe 13 is provided with The blowdown valve 12 is characterized in that the working oil pipe 15 is provided with an on-off control valve 5, the top of the box 10 is provided with a connecting pipe 1, and the connecting pipe 1 is provided with a throttling orifice group 2 for throttling The orifice plate group 2 is connected with a pre-pressurized air filter 3 through an overflow pipe 4. An overflow port 4-1 is provided on the middle side of the overflow pipe 4, and an oil return pipe 18 is connected to the overflow port 4-1. The oil return pipe 18 is provided with an oil return peek port 17 .

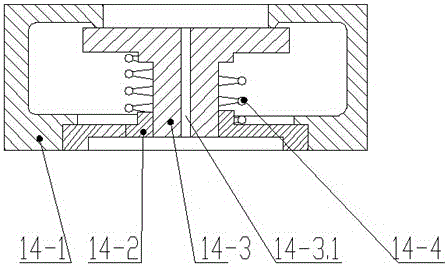

[0046] The throttle orifice group 2 includes an upper orifice 2-1 and a lower orifice 2-3, and a channel pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com