Electric motorcycle concave-convex friction transmission side-mounted adaptive variable speed drive assembly

A technology of electric motorcycles and friction transmission, which is applied in the direction of vehicle gearboxes, wheel transmissions, transmissions, etc., can solve problems such as not being able to meet road use, achieve small axial dimensions, increase friction surfaces, and smooth load changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

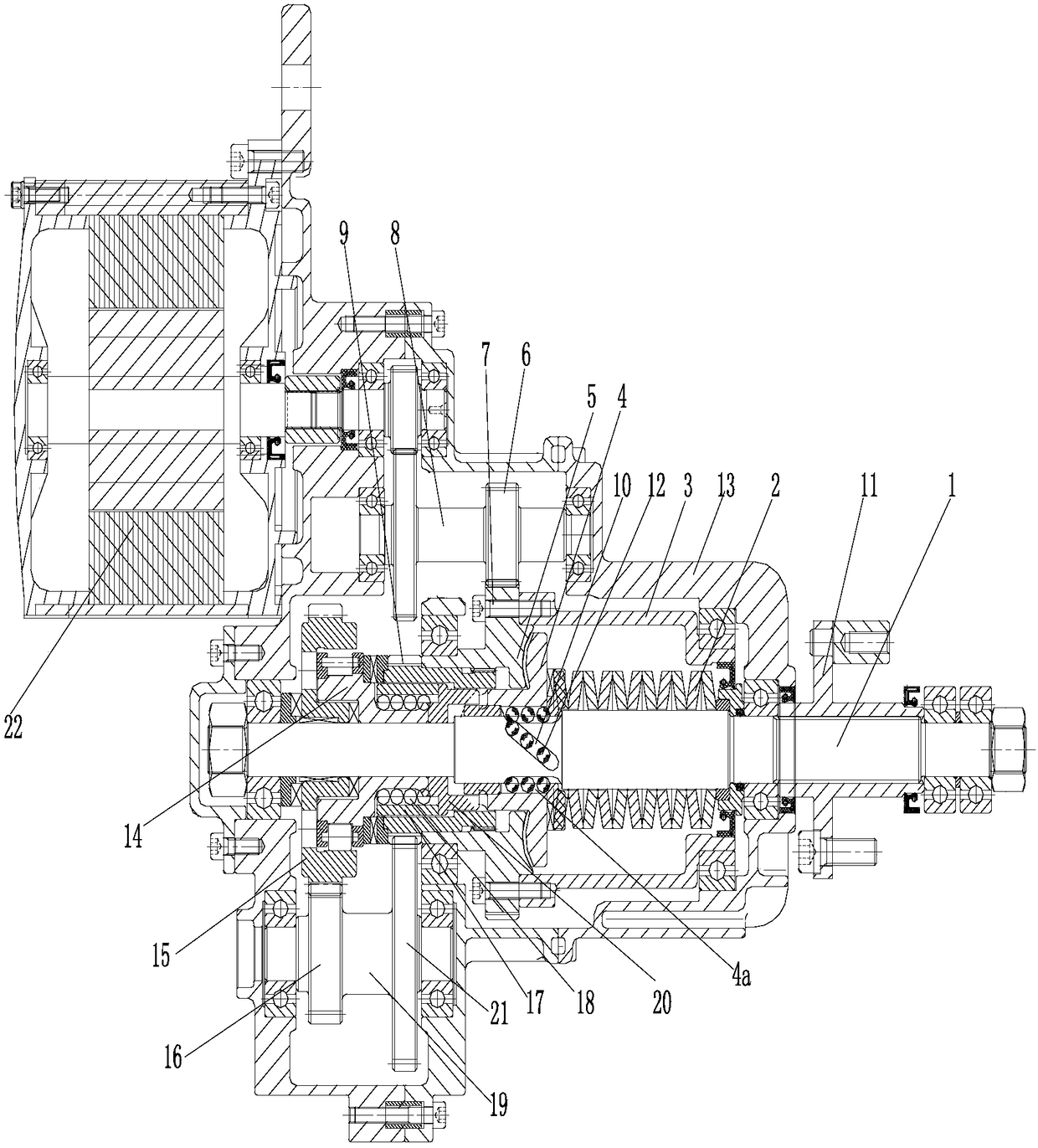

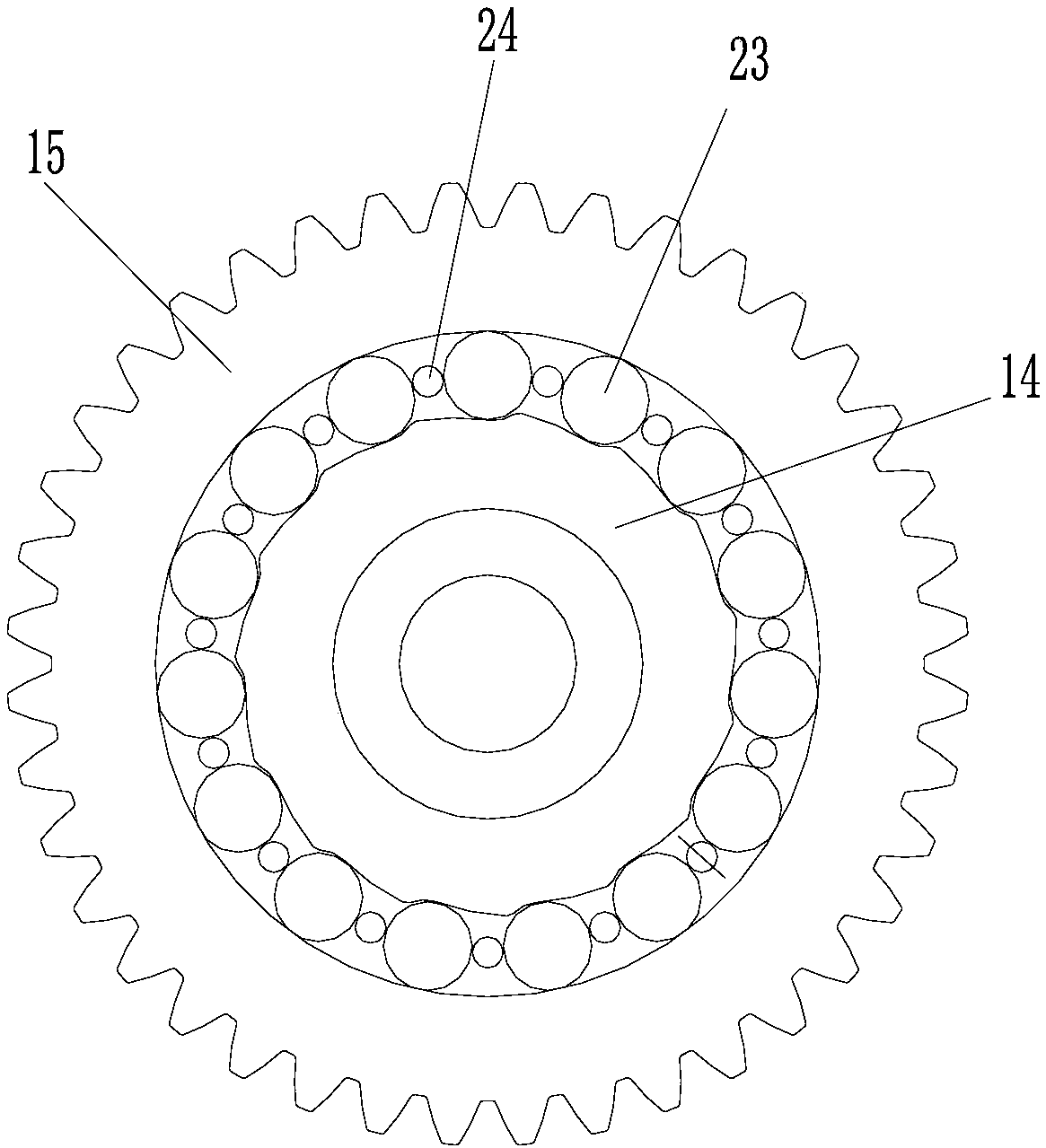

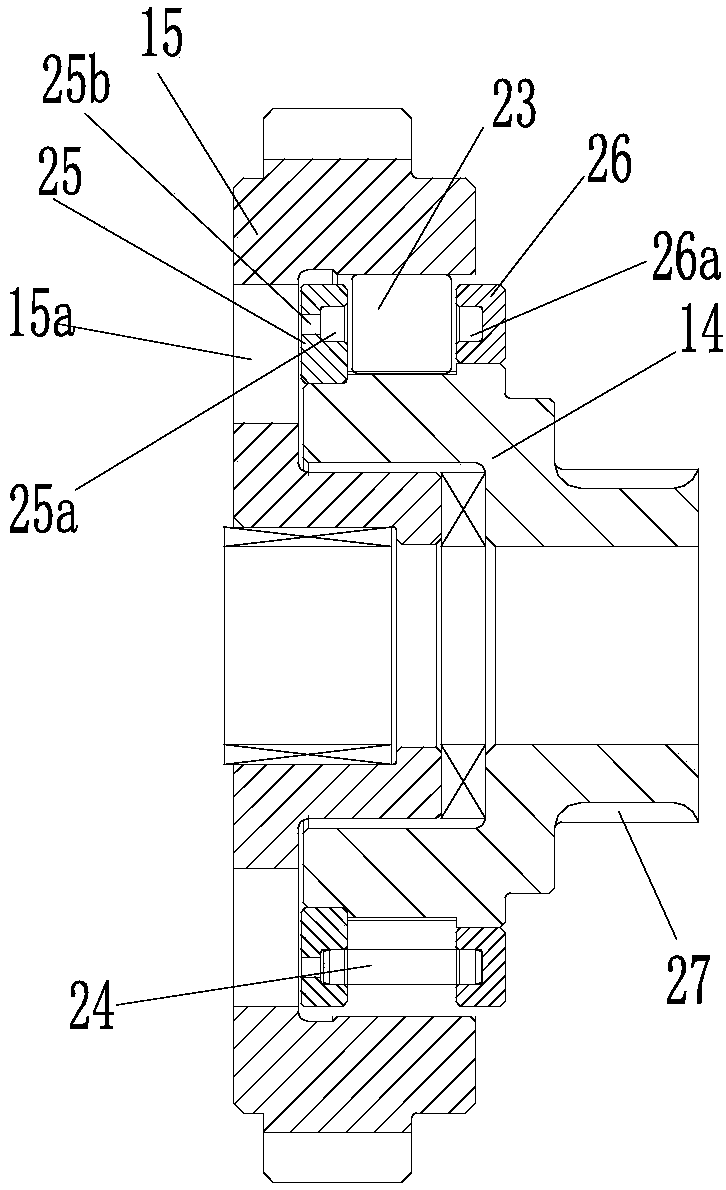

[0025] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 Schematic diagram of the structure of the overrunning clutch, image 3 is the circumferential sectional view of the overrunning clutch, Figure 4 Another structure of the concave-convex friction transmission pair of the present invention is shown in the figure; the concave-convex friction transmission side-mounted adaptive variable speed drive assembly of the electric motorcycle of the present invention includes a box body 13 and a box body 13 that rotates and fits The transmission shaft 1 of the power output, the box body 13 has a mounting part for side hanging on the hub side, when in use, the motor is fixedly connected to the box body 13, and the box body 13 is fixedly connected to the vehicle frame on the wheel hub side, forming side hanging structure;

[0026] It also includes a slow gear transmission mechanism and a mechanical intelligent adaptive transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com