Test device and measurement method for fatigue crack growth rate in seawater corrosive environment

A technology for fatigue crack growth and rate testing, applied in the field of fatigue crack growth rate testing devices under seawater corrosion environment, can solve the problems of heat generation, influence the validity of test results, and strict sealing performance requirements, and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

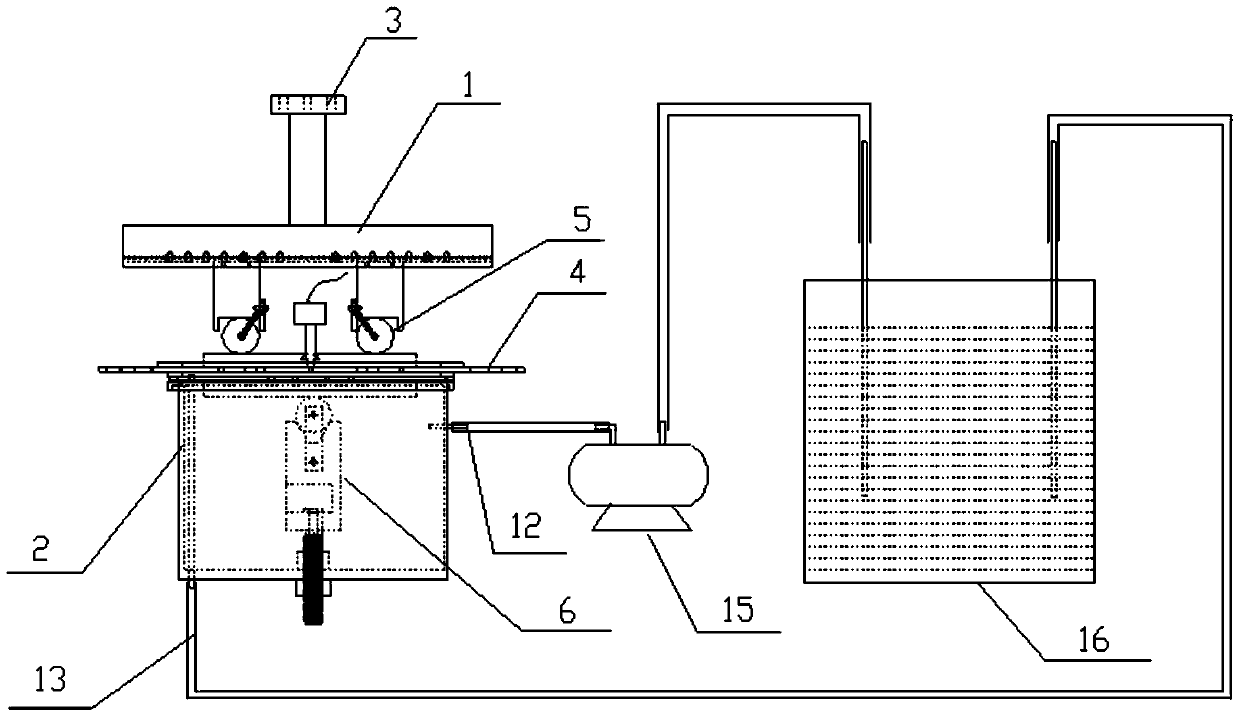

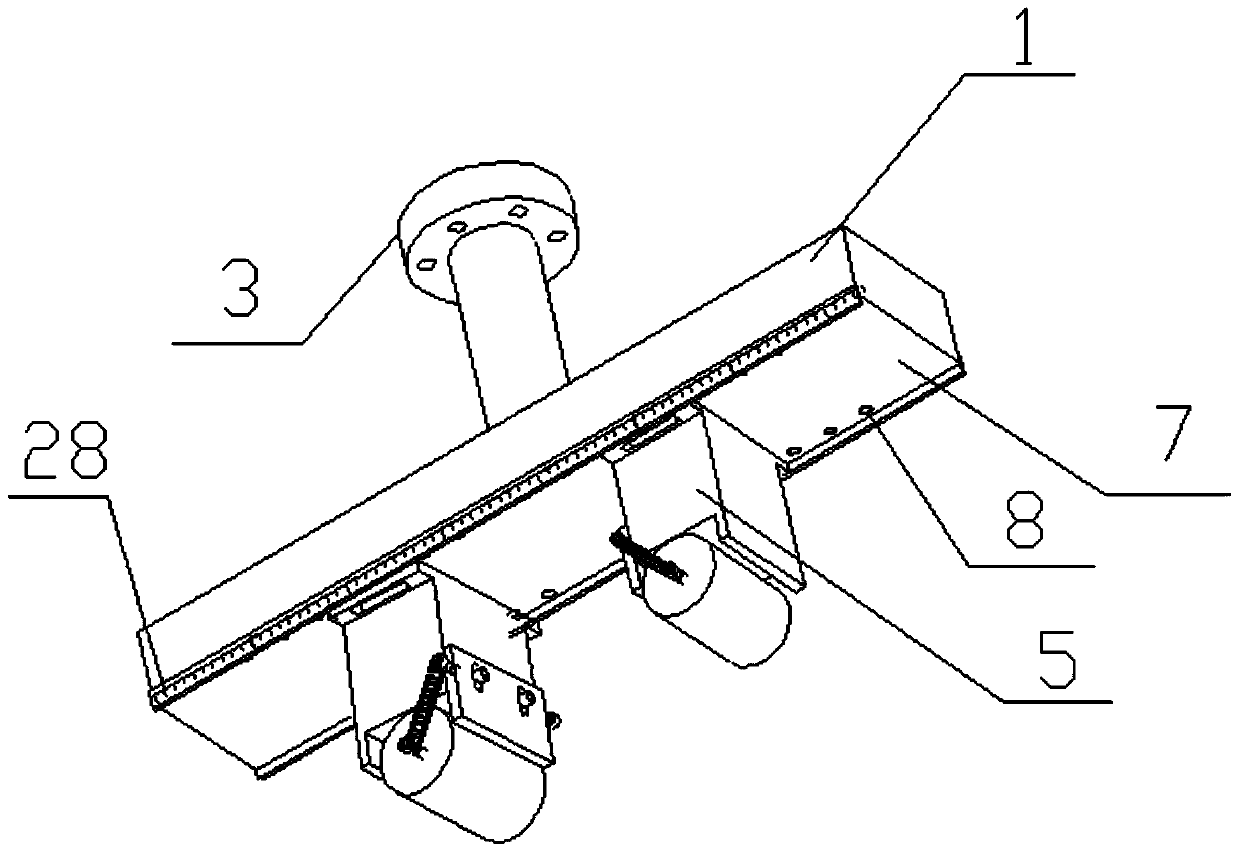

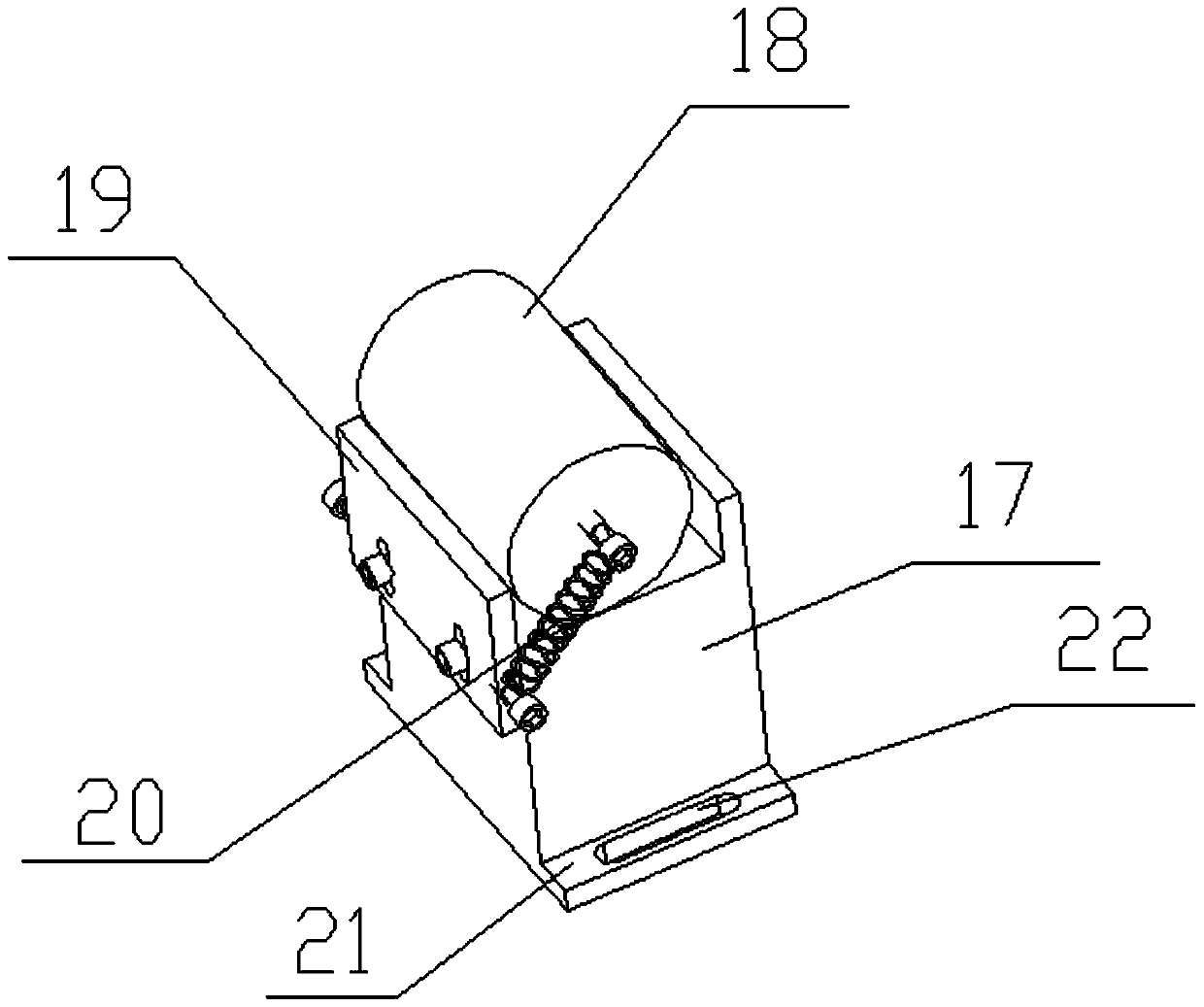

[0037] Such as figure 1 The shown inventive device for fatigue crack growth rate test under seawater corrosion environment includes a three-point bending fixture and a seawater environment container box 2 . The three-point bending fixture is composed of a three-point bending support 1 connected to the crossbeam of the fatigue testing machine, two upper bending center fixtures 5 connected on the three-point bending support 1, and a lower bending center arranged in the seawater environment container box 2 The fixture consists of 6 components. The seawater environment container box 2 is connected with a circulating seawater supply device located outside the seawater environment container box. The circulating seawater supply device includes a circulating seawater tank 16 and a circulating water pump 15. The bottom of the seawater environment conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com