Detection method for permeability of cigarette burning cone

A detection method and combustion cone technology are applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., to achieve the effect of convenient and reliable implementation steps and accurate and reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

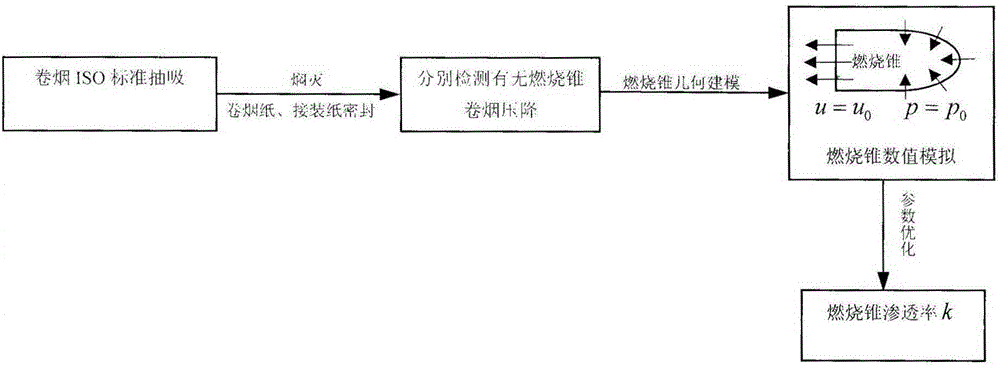

Method used

Image

Examples

Embodiment 1

[0013] 1) Place a certain brand of cigarette samples in a constant temperature and humidity room with a temperature of 22±2°C and a relative humidity of 60±5% for 48 hours to balance, and select a number of cigarettes. Single weight ±5mg;

[0014] 2) After igniting the cigarette, perform ISO standard smoking (2s, 35ml). Within 3s after the end of the first puff, put the cigarette in a nitrogen atmosphere to extinguish it, and keep the cigarette burning cone intact during the process;

[0015] 3) Seal the cigarette paper and tipping paper, connect a measuring instrument with a pressure sensor to the single-channel smoking machine, and detect the pressure drop of the cigarette with the combustion cone under the airflow velocity of 17.5ml / s; cut off the cigarette Combustion cone, to detect the pressure drop of a cigarette without a combustion cone at the same air flow rate; the difference between the two pressure drops is the pressure drop of the combustion cone at the flow rate ...

Embodiment 2

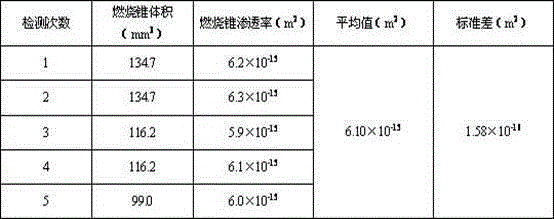

[0021] See Table 2 for the combustion cone detection results at the end of the second puff of a cigarette of a certain brand according to the ISO standard:

[0022] Table 2 Combustion cone penetration rate data after smoking the second cigarette

[0023]

Embodiment 3

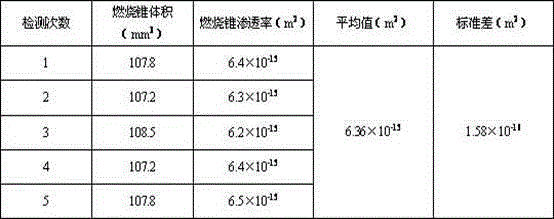

[0025] The combustion cone detection results at the end of the third puff of a certain brand of cigarette ISO standard are shown in Table 3:

[0026] Table 3 Combustion cone penetration rate data after the third puff of the cigarette

[0027]

[0028] It can be seen from the above examples that the method of the present invention can obtain the permeability parameter data of the cigarette combustion cone, and the detection method has the characteristics of high process repeatability and small standard deviation of results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com