Light guide element and solar cell module

A technology of solar cells and solar cells, which is applied to optical components, photovoltaic power generation, electrical components, etc., and can solve the problem of insufficient utilization of sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

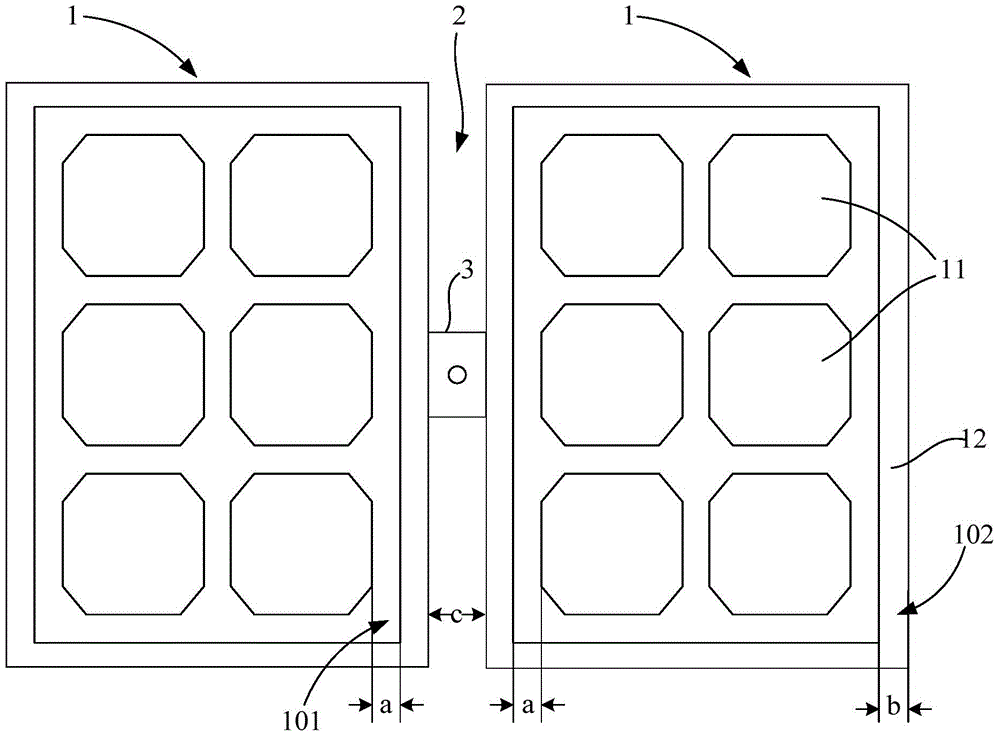

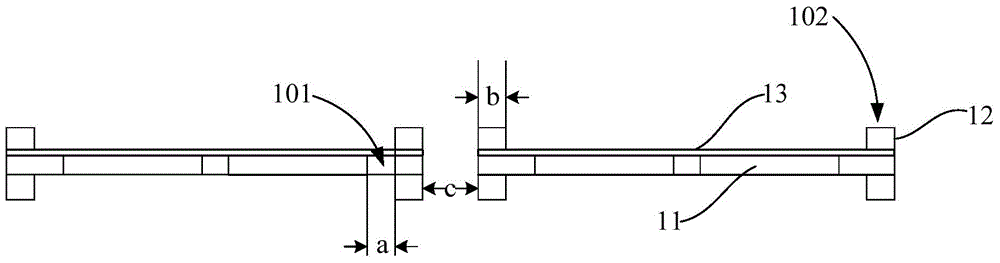

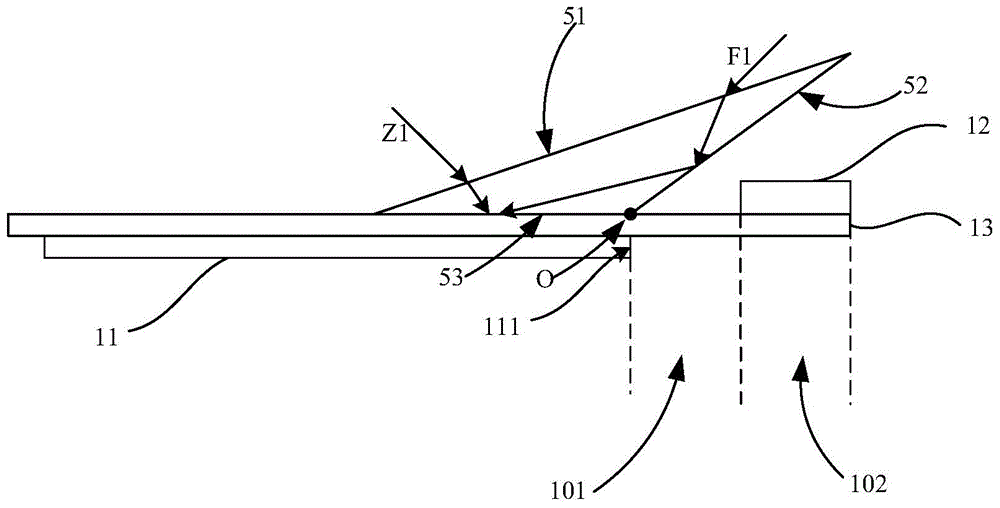

[0136] refer to Figure 4 , the gap between the two dotted lines is the first gap 101 and the width 102 of the frame, the light beam incident to the gap enters the light guide element from the incident surface 51, and directly exits from the outgoing surface 53 to the battery sheet through refraction.

Embodiment 2

[0138] refer to Figure 5 , the two dotted lines still represent the gap formed by the width of the first gap and the frame, and the incident light perpendicular to the gap enters the incident surface for divergent refraction, and then is reflected by the reflective surface and exits from the outgoing surface to the solar cell sheet.

Embodiment 3

[0140] The principle of embodiment 3 is basically the same as that of embodiment 2, the only difference is that it is not vertical incidence, refer to Figure 6 , the incident light obliquely incident to the gap enters the incident surface for divergent refraction, and then is reflected by the reflective surface and exits from the outgoing surface to the solar cell sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com