Optical echo wall micro-cavity structure etched by focused ion beam and method for etching same with focused ion beam

A technology of focusing ion beams and whispering galleries, applied in the coupling of optical waveguides, etc., can solve the problems of complex microsphere filling process, and achieve the effect of lower threshold and high sensing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

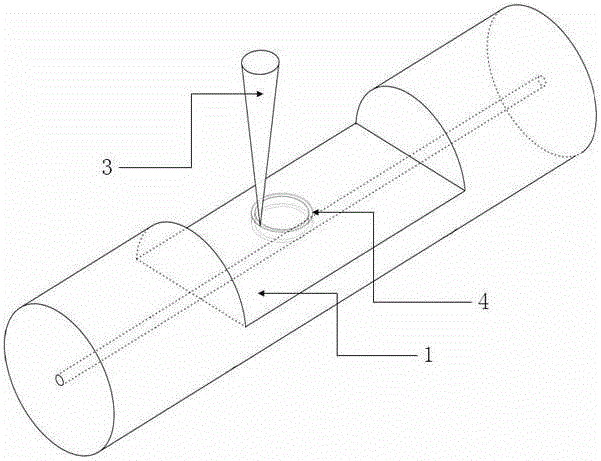

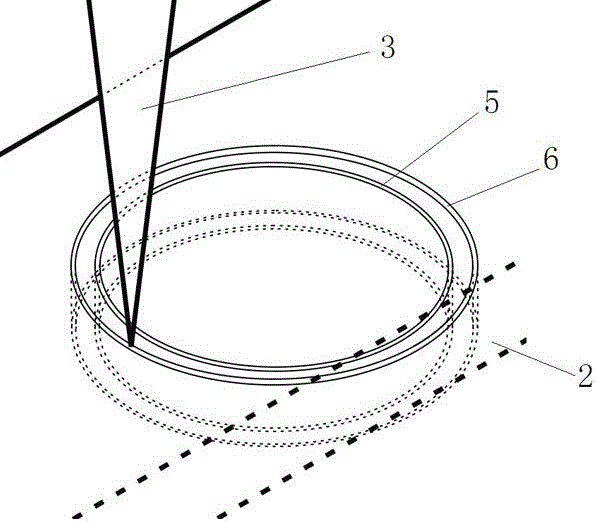

[0021] An optical whispering gallery microcavity structure processed by focused ion beam etching, including an optical fiber 1, the innovation of which is: a plane is arranged on the circumferential side wall of the optical fiber 1, the plane is parallel to the axis of the optical fiber 1, and the plane is parallel to the axis of the optical fiber 1. There is a distance between the cores of the optical fiber 1; two annular grooves are arranged on the plane, the axial direction of the annular groove is perpendicular to the plane, the two annular grooves have the same center, and the axial depths of the two annular grooves are the same; The solid part between the two annular grooves forms an annular protrusion, the radial width of the annular protrusion is smaller than the diameter of the fiber core; the annular protrusion intersects the fiber core; the fiber core is in the axial direction of the annular protrusion The location is within the axial span range of the annular protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com