Photo anode modifying method for improving stability of dye-sensitized solar cells

A technology of solar cells and dye sensitization, which is applied in the field of solar cells, can solve problems such as damaging photoelectric performance, and achieve the effects of improving stability, low cost, and increasing reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of one-dimensional structure titania nanowires by hydrothermal preparation

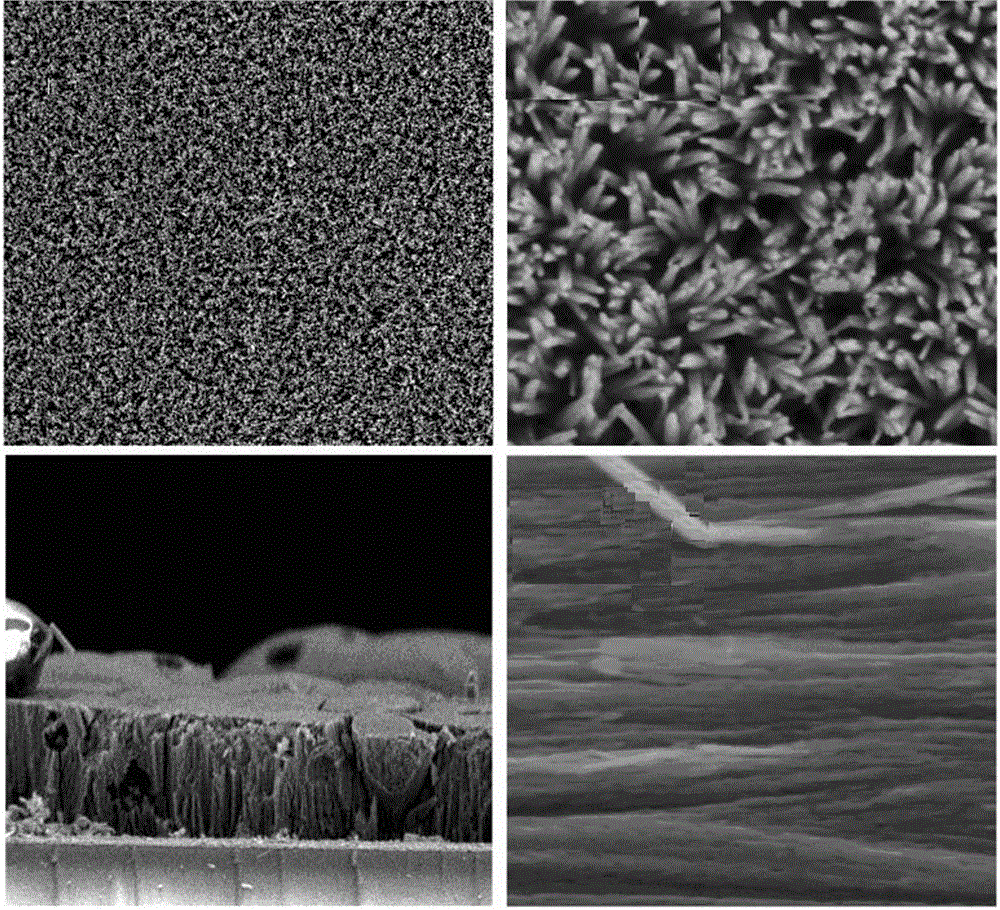

[0026] A 10mm×20mm fluorine-doped tin oxide conductive glass (FTO) substrate was ultrasonically washed with acetone, 2-isopropanol, ethanol, and secondary water for 15 minutes, respectively. Place the cleaned FTO conductive glass sheet against its side in a 25mL reaction kettle, and add the precursor solution (10mL toluene, 1mL concentrated hydrochloric acid, 1mL n-butyl titanate). at 180 o C under the condition of reaction 10h. After the reactor was naturally cooled, the FTO substrate was taken out, rinsed with ethanol and placed in a muffle furnace at 450 o Calcined at C for 0.5h to obtain the titania nanowire array structure ( figure 1 ), with a diameter of 40nm and a length of 4μm.

Embodiment 2

[0027] Example 2: Silanization Treatment of Titanium Dioxide Nanowire Array Surface

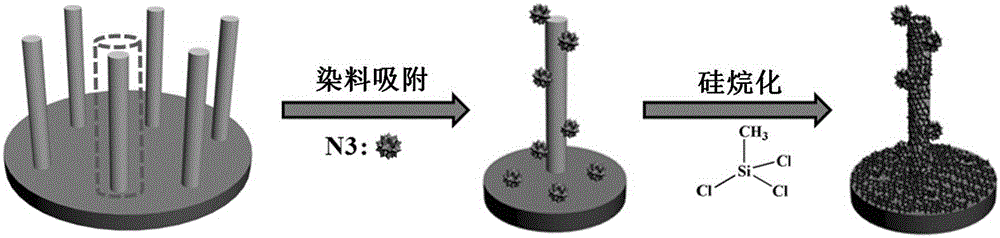

[0028] Soak the titanium dioxide nanowire array synthesized above in an ethanol solution containing a ruthenium bipyridine complex dye for 24 hours to make it adsorb dye molecules. The silanization treatment was carried out in a closed container equipped with a gas inlet and outlet valve. The titanium oxide nanowire array after the dye adsorption was placed in the reactor, and nitrogen gas was passed in for 30 minutes, the relative humidity was controlled at 12%, and 0.5 mL of trichloro Methylsilane. The reaction time was controlled at 0, 5, 10, 20, 30, 40, 50 min, respectively. After silanization, rinse the titanium dioxide surface with pyridine (5%) in acetonitrile, 150 o C for 10 min to obtain a silanized photoanode.

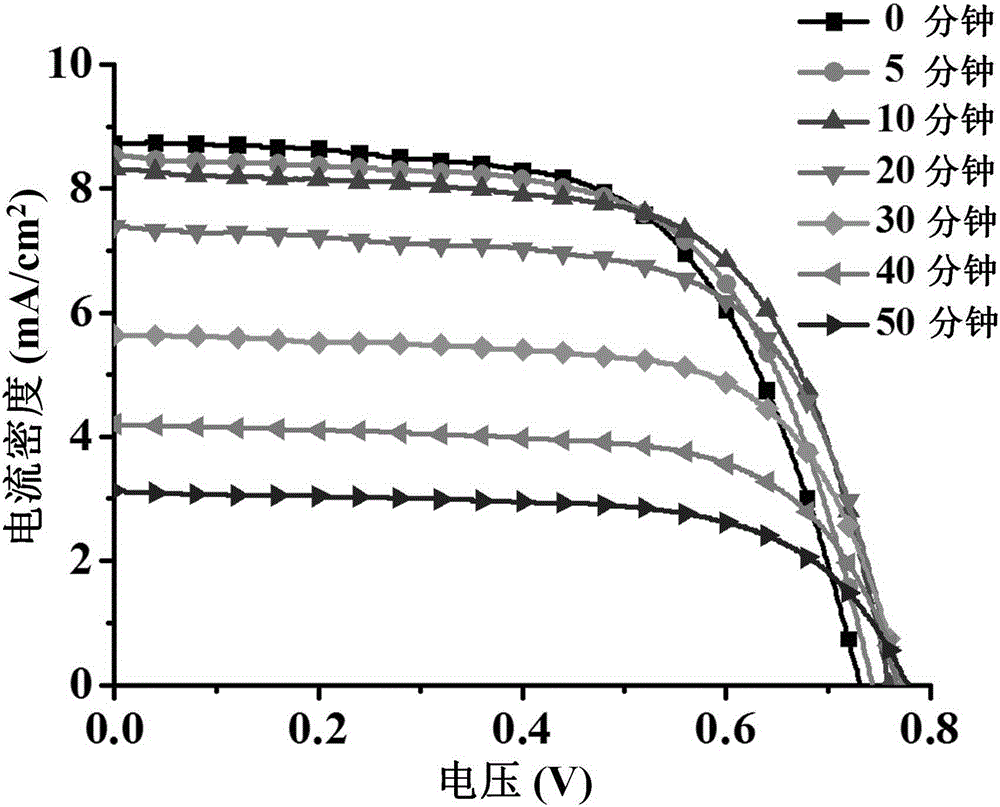

[0029] The photoanodes after silanization treatment at different times were assembled into cells for photovoltaic performance testing. The counter electrode of the bat...

Embodiment 3

[0032] Example 3: Stability test of silanized photoanodes

[0033] The modified photoanode obtained above was placed in the air for 0, 5, 10, 15, 20, 25, and 30 days, respectively, and then the operability was measured. See Example 2 for the test method. And the titanium dioxide nanowire array electrode with dye molecules attached without silanization treatment was compared, and the results Such as Figure 4 shown. Through comparison, it is confirmed that the modified photoanode obtained in the present invention can still maintain its original photoelectric performance after 30 days, and has good stability.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap