Temperature protector and a preparation method thereof

A technology of temperature protector and thermal fuse, applied in the direction of heating/cooling contact switch, etc., can solve the problems of poor sealing, slow heat conduction, failure of thermal fuse, etc., and achieve the effect of good sealing, high heat conduction speed and sensitive heat conduction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] On the other hand, an embodiment of the present invention provides a method for preparing the above-mentioned temperature protector, including: using a terminal to electrically connect the temperature fuse to an insulated wire, and then placing it inside the casing; then, filling the inside of the casing with polyurethane resin, so that The polyurethane resin fills the inside of the case, and then cured at 20-25°C for 7-10 hours to obtain the desired temperature protector.

[0047] Specifically, the method for preparing a temperature protector provided by an embodiment of the present invention may include the following steps: Step 101, use the first terminal to electrically connect one end of the thermal fuse to the first insulated wire, and use the second terminal to connect the other end of the thermal fuse to Electrically connected to a second insulated wire and then placed inside the housing.

[0048] Step 102: Accurately weigh the mass of the polyurethane resin mai...

Embodiment 1

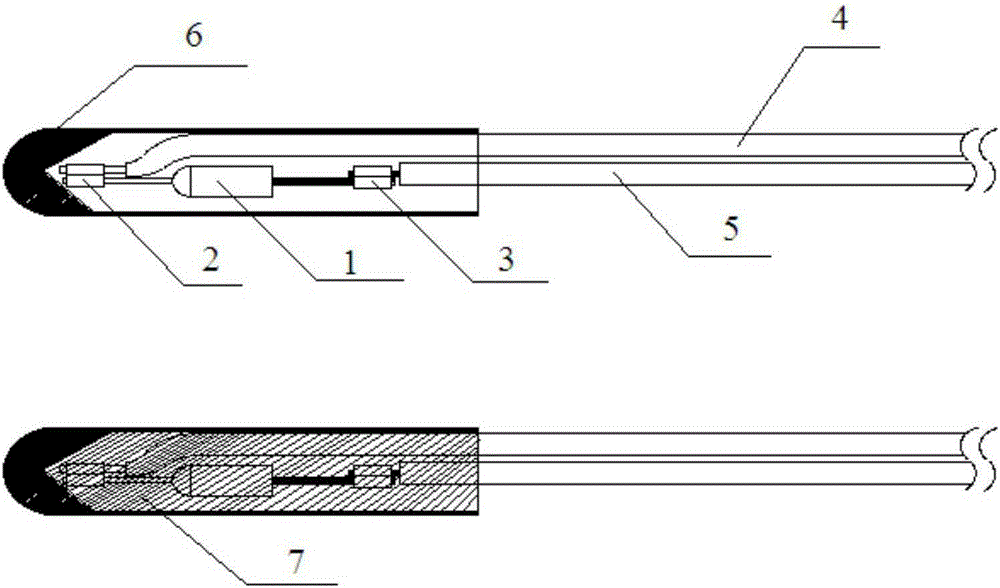

[0057] This embodiment provides a temperature protector, including: a casing, a temperature fuse, terminals and insulated wires. Both ends of the thermal fuse are electrically connected to two insulated wires through two terminals, and placed inside the housing, wherein the thermal fuse, terminals and part of the insulated wires in the housing are not in contact with the inner wall of the housing, and are filled with polyurethane in the housing. The resin seals the thermal cutoff inside the housing.

[0058] Wherein, the mass ratio of the polyurethane resin main agent and the polyurethane resin curing agent in the polyurethane resin is 100:15. The material of the shell is flame retardant nylon.

[0059] The temperature protector prepared in Example 1 can be used for 5 years under normal use.

Embodiment 2

[0061] This embodiment provides a temperature protector, including: a casing, a temperature fuse, terminals and insulated wires. Both ends of the thermal fuse are electrically connected to two insulated wires through two terminals, and placed inside the housing, wherein the thermal fuse, terminals and part of the insulated wires in the housing are not in contact with the inner wall of the housing, and are filled with polyurethane in the housing. The resin seals the thermal cutoff inside the housing.

[0062] Wherein, the mass ratio of the polyurethane resin main agent and the polyurethane resin curing agent in the polyurethane resin is 100:16. The material of the shell is flame retardant nylon.

[0063] The temperature protector prepared in Example 2 can be used for 5.5 years under normal use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com