Photoelectric detector assembly

A technology of photodetectors and components, applied in military and national economic fields, can solve the problems of photoresponsivity and photosensitive area limitation, cost increase, and inability to adapt to mass production, etc., to achieve the effect of improving optical power response and increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

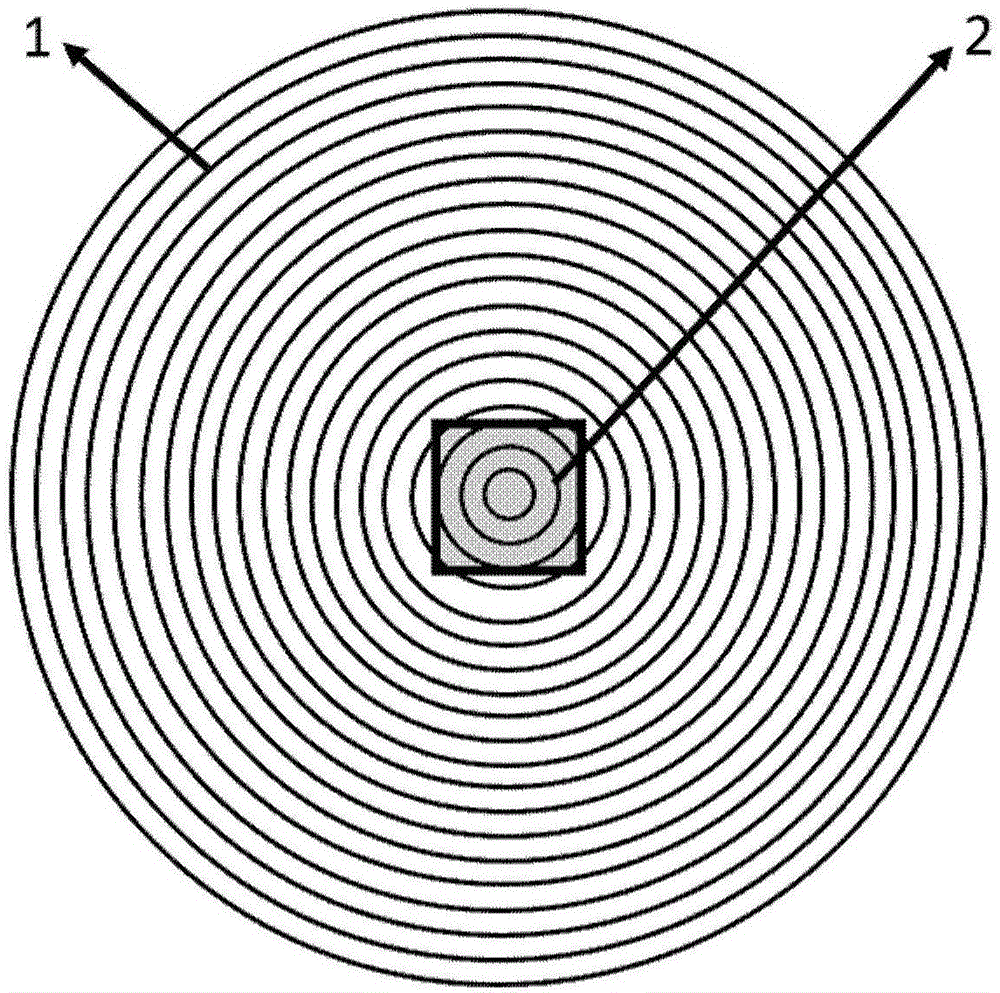

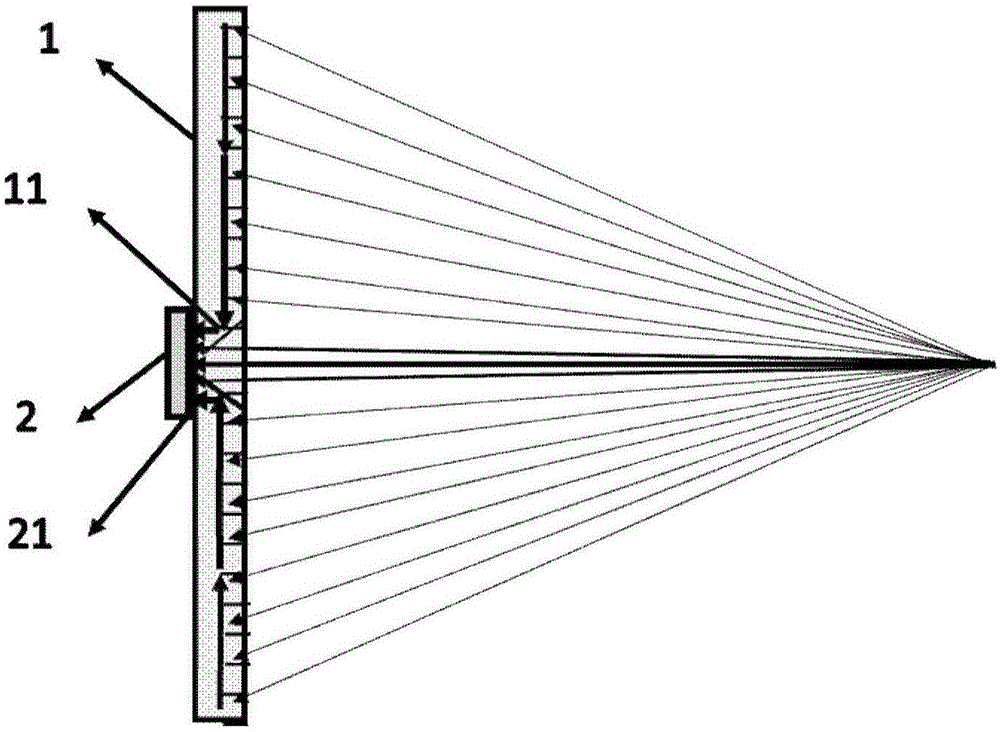

[0011] See figure 1 and figure 2 As shown, the present invention provides a photodetector assembly, which includes:

[0012] A waveguide grating 1, the shape of the waveguide grating 1 can be any shape according to the needs of use, which changes the optical power incident on its surface and the propagation direction of the optical signal through the diffraction and refraction effects of the grating, and collects and collects the optical power and the optical signal. Convergence, the material of the waveguide grating 1 is any one of silicon on the insulating layer, silicon-based silicon dioxide, silicon dioxide, glass, and polymer. The grating of the waveguide grating 1 is designed according to the requirements of use and passed The processing technology of electron beam direct writing, photolithography, plasma etching or electron beam exposure is completed. The waveguide grating 1 has a light exit hole 11 in the center. The grating is distributed from the inside to the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com