Method for manufacturing mosquito sucking mat for mosquito sucking device

A manufacturing method and technology of a mosquito aspirator, which are applied to the application, devices for catching or killing insects, animal husbandry, etc., can solve the problems of poor mosquito trapping effect of the mosquito aspirator, increase the number of mosquitoes killed, increase the attracting rate, Good lure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

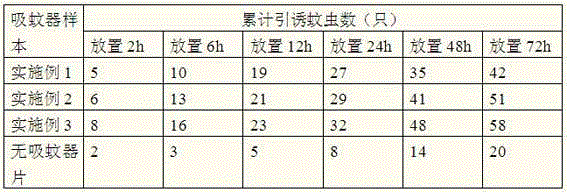

Embodiment 1

[0012] The mosquito-absorbing sheet for mosquito inhalers of this embodiment includes a tablet core and a coating film, wherein the tablet core is made of the following components in parts by weight: 52 parts of magnesium carbonate, 90 parts of citric acid, 30 parts of calcium chloride, and 35 parts of starch parts, 20 parts of β-cyclodextrin, 50 parts of ethyl cellulose; the coating film is made of the following components by weight: 10 parts of carboxymethyl cellulose, 2.5 parts of liquid paraffin, 5 parts of shellac powder and 110 parts of ethanol.

[0013] The production steps are as follows: Dissolve magnesium carbonate in citric acid, then add calcium chloride, starch, β-cyclodextrin and ethyl cellulose and mix evenly, wet the granules through a 24-mesh oscillating granulator, and place the wet granules in Dry in a drying oven at 40°C for 45 minutes, press into a tablet to obtain a tablet core; stir carboxymethylcellulose, liquid paraffin and ethanol evenly, spray coatin...

Embodiment 2

[0015] The mosquito-absorbing sheet for mosquito inhalers of this embodiment includes a tablet core and a coating film, wherein the tablet core is made of the following components in parts by weight: 70 parts of magnesium carbonate, 120 parts of citric acid, 40 parts of calcium chloride, and 55 parts of starch 8 parts, 8 parts of β-cyclodextrin, 65 parts of ethyl cellulose; The coating film is made of the following components by weight: 15 parts of carboxymethyl cellulose, 4 parts of liquid paraffin, 3 parts of shellac powder and 125 parts of ethanol.

[0016] The production steps are as follows: Dissolve magnesium carbonate in citric acid, then add calcium chloride, starch, β-cyclodextrin and ethyl cellulose and mix evenly, wet the granules through a 24-mesh oscillating granulator, and place the wet granules in Dry in a drying oven at 45°C for 30 minutes, press into a tablet to obtain a tablet core; stir carboxymethyl cellulose, liquid paraffin and ethanol evenly, spray coati...

Embodiment 3

[0018] The mosquito-absorbing sheet for mosquito inhalers of this embodiment includes a tablet core and a coating film, wherein the tablet core is made of the following components in parts by weight: 60 parts of magnesium carbonate, 100 parts of citric acid, 35 parts of calcium chloride, and 40 parts of starch parts, 15 parts of β-cyclodextrin, 60 parts of ethyl cellulose; the coating film is made of the following components by weight: 12 parts of carboxymethyl cellulose, 3 parts of liquid paraffin, 4 parts of shellac powder and Parts ethanol 120.

[0019] The production steps are as follows: Dissolve magnesium carbonate in citric acid, then add calcium chloride, starch, β-cyclodextrin and ethyl cellulose and mix evenly, wet the granules through a 24-mesh oscillating granulator, and place the wet granules in Dry in a drying oven at 40°C for 40 minutes, press into a tablet to obtain a tablet core; stir carboxymethyl cellulose, liquid paraffin and ethanol evenly, spray coating o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com