Efficient waste gas purifying device based on microwave catalysis

A technology of microwave catalysis and purification device, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of human plant damage, quality deterioration, plant damage, etc., achieve precise control of waste gas treatment, and increase service life. , to ensure the effect of purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing of description, the present invention will be further described.

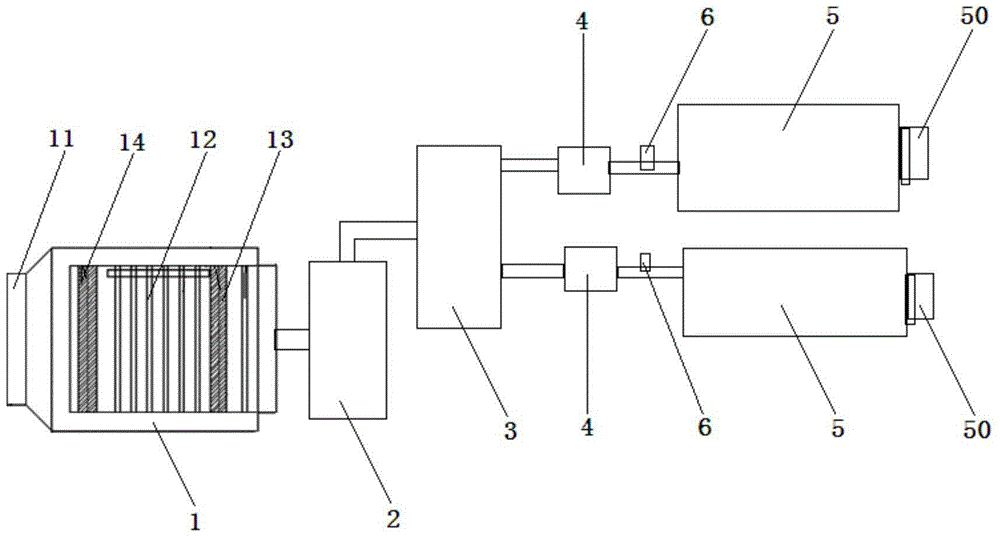

[0023] Such as figure 1 As shown, a high-efficiency exhaust gas purification device based on microwave catalysis includes a spray device 1, a gas dehydration unit 2, a gas delivery device 3, a gas flow control device 4 and a microwave catalytic device 5, and one end of the spray device 1 is provided There is a waste gas inlet 11, the other end is connected to the air inlet of the gas dehydration unit 2, the gas inlet of the gas delivery device 3 is connected to the gas outlet of the gas dehydration unit 2; the two ends of the gas flow control device 4 are respectively connected to microwave The gas inlet of the catalytic device 5 and the gas outlet of the gas delivery device 3; the exhaust gas enters the spray device 1 through the exhaust gas inlet 11 and is initially purified, and then enters the microwave catalysis through the gas dehydration unit 2, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com