Industrialized regeneration method of SCR plate-type denitration catalyst

A denitrification catalyst and catalyst technology, applied in the field of denitrification catalysts, can solve problems such as deactivation and failure to restore initial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 of the present invention provides a factory regeneration method for an SCR plate denitration catalyst.

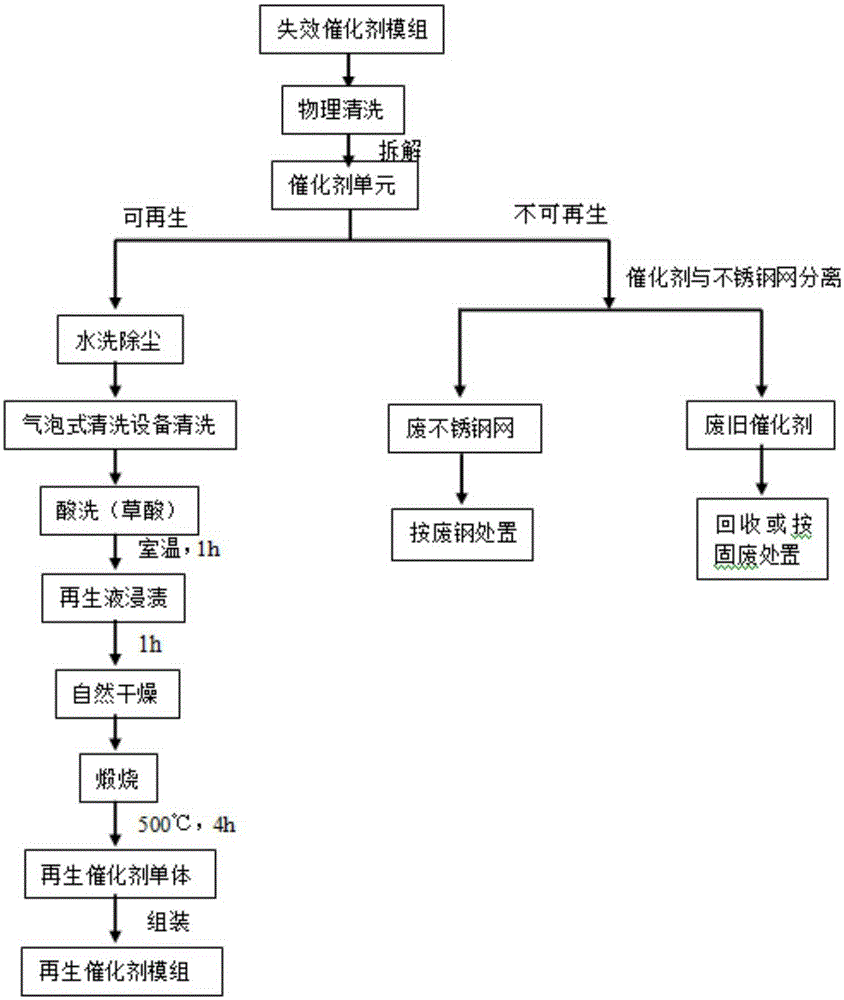

[0026] see figure 1 , The regeneration of deactivated SCR denitrification catalyst mainly includes several steps: physical cleaning→catalyst module disassembly→catalyst unit (single box catalyst)→regeneration analysis→renewable catalyst dedusting (water washing dedusting and bubble cleaning equipment cleaning dedusting)→ Pickling → impregnation in regeneration solution → drying → calcination → assembly into a catalyst module.

[0027] (1) Physical cleaning: The main purpose of physical cleaning is to sweep away impurities such as floating dust attached to the surface of the catalyst. The catalyst module is placed in a special purge bed, blown with compressed air, and the blown dust is collected in the ash hopper for centralized treatment.

[0028] (2) Regeneration analysis: The deactivation of the catalyst caused by thermal sintering and mechanical ero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com