Multi-channel liquid transfer device

A transfer device and multi-channel technology, applied in the field of biomedicine, can solve the problems of time-consuming and laborious manual operation, and achieve the effects of convenient operation, simple structure and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

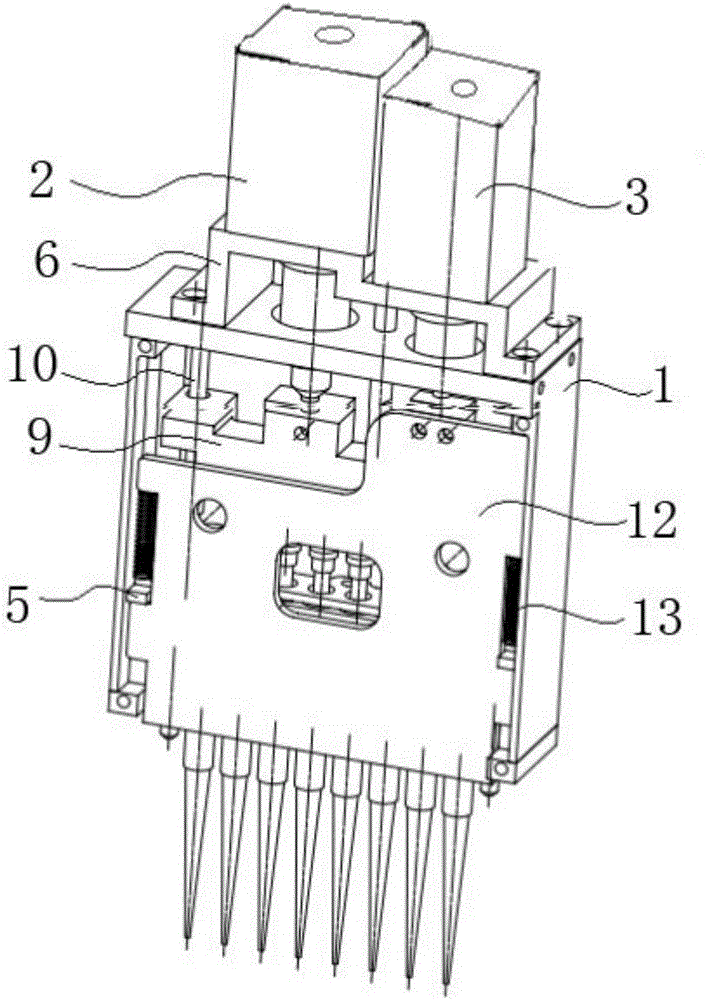

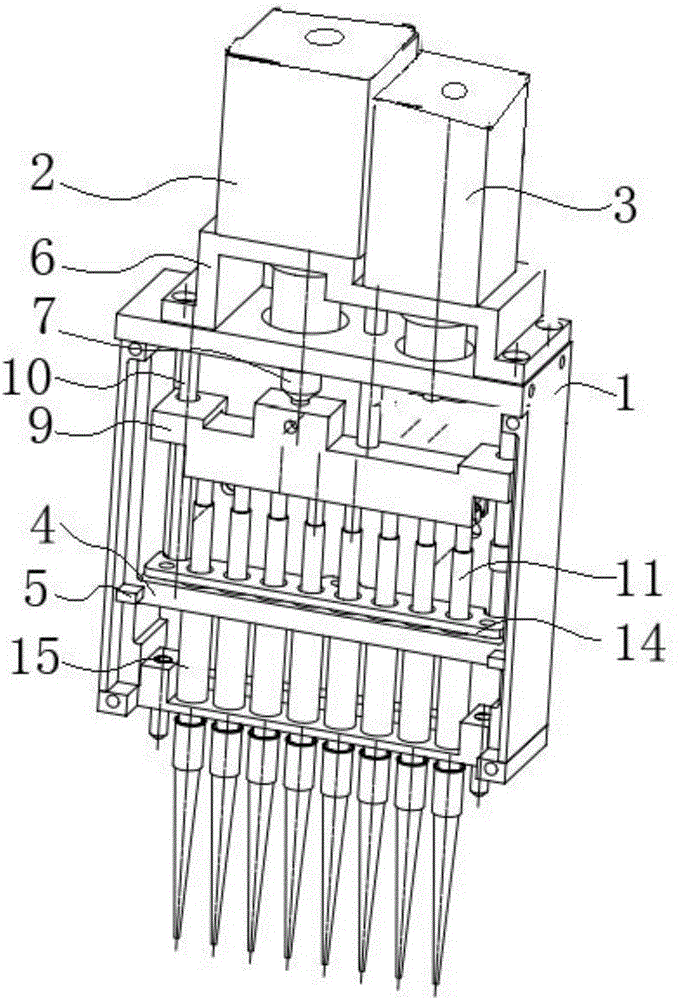

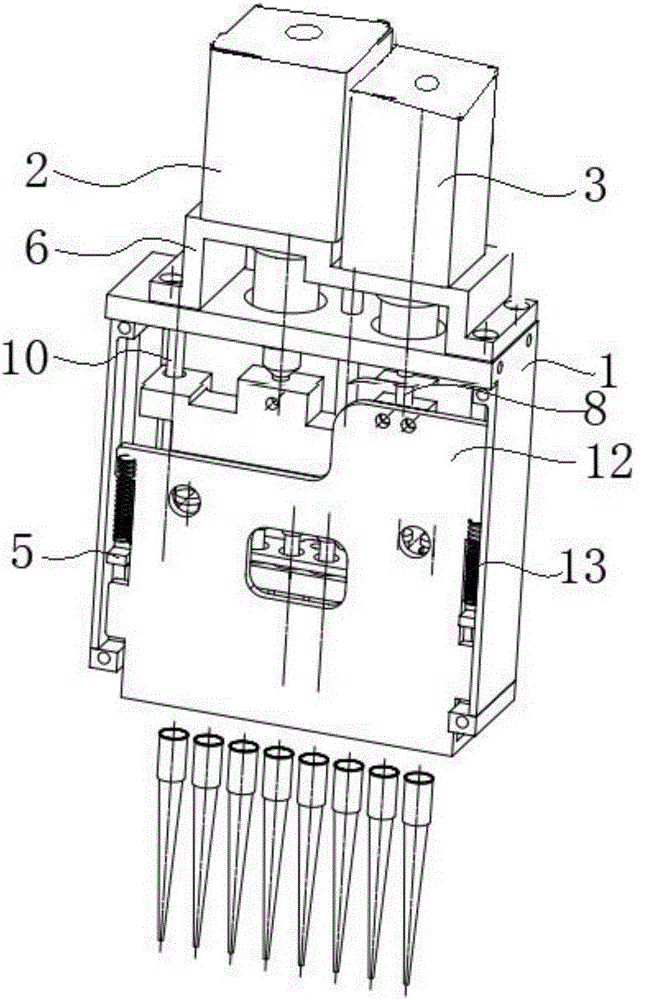

[0018] Such as figure 1 , 2 As shown in , 3, a multi-channel liquid transfer device includes a housing 1 with a front opening, and the housing 1 is processed from a monolithic metal piece; a first drive motor 2 is fixed on the top of the housing 1 through a motor bracket 6 The first transmission screw rod 7 of the first drive motor 2 passes through the top of the casing and is connected to the slider 9 arranged in the casing. A vertical guide post 10 is respectively arranged on the inside of the casing 1 close to the two side walls. Block 9 two ends perforate pass vertical guide post, make slide block keep horizontal state when moving up and down. Eight piston rods 11 with pistons are evenly arranged on the bottom of the slider 9 . Specifically, the middle of the slider 9 protrudes downwards, and the bottom of the protruding end is provided with a plurality of slots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com