Machining device and process for heat-pipe capillary structure

A capillary structure and processing device technology, which is applied in the field of heat pipes, can solve the problems of inability to realize multi-layer powder sintering, complex manufacturing process, and more requirements for personnel, equipment, and tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

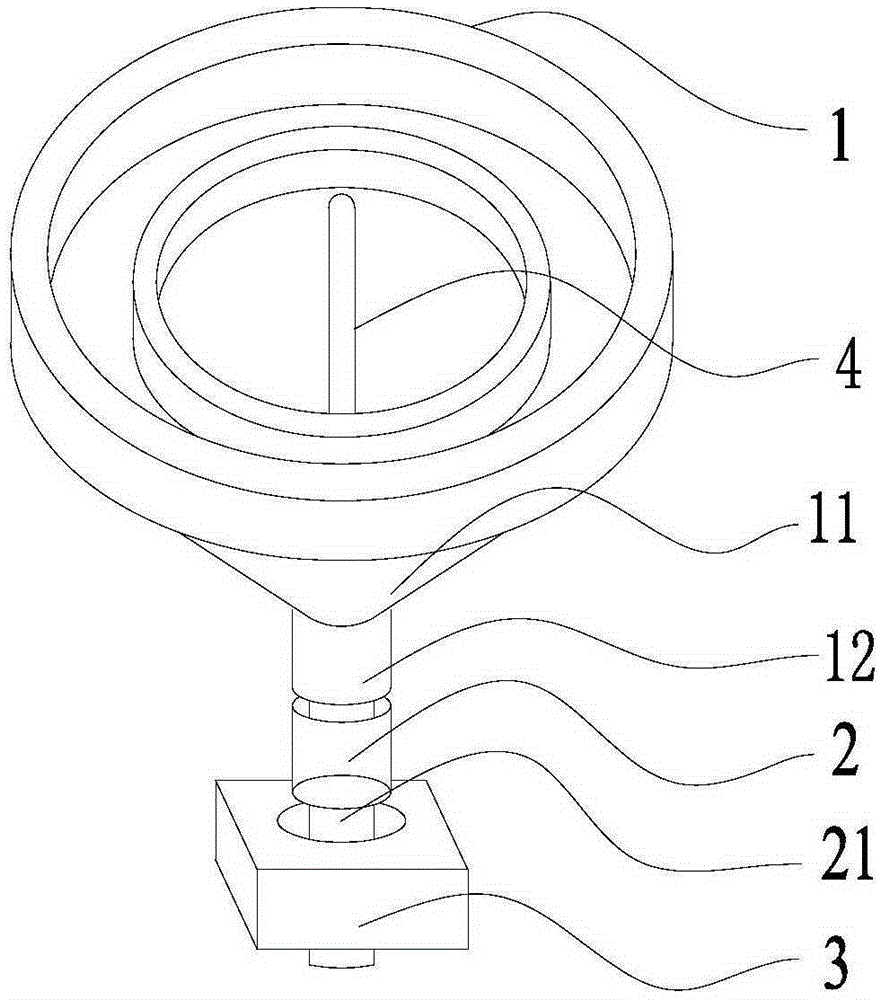

[0023] Attached below figure 1 and specific embodiments to further illustrate the technical solutions of the present invention.

[0024] Such as figure 1 As shown, a heat pipe capillary structure processing device of the present invention includes a powder mixing mechanism 1, a shaping mechanism 2, and a sintering mechanism 3; the powder mixing mechanism 1 includes at least two coaxially nested powder storage funnels 11, and the powder storage The size of the funnel 11 gradually increases from the inside to the outside, and the lower end of each powder storage funnel 11 is connected with a pipe body 12, and the inner wall of each pipe body 12 is provided with a spiral groove; the shaping mechanism 2 is connected to the lower end of the pipe body 12, The inside of the shaping mechanism 2 is provided with a through hole. The top of the sintering mechanism 3 is provided with a positioning shaft 21 , and the top of the positioning shaft 21 passes through the through hole of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com