Loop test track for vacuum pipeline high-temperature superconducting magnetic levitation train

A vacuum pipeline and high-temperature superconducting technology, which is applied in roads, tracks, motor vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

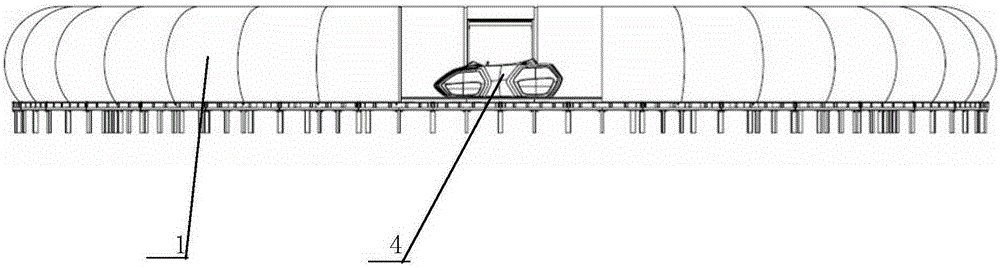

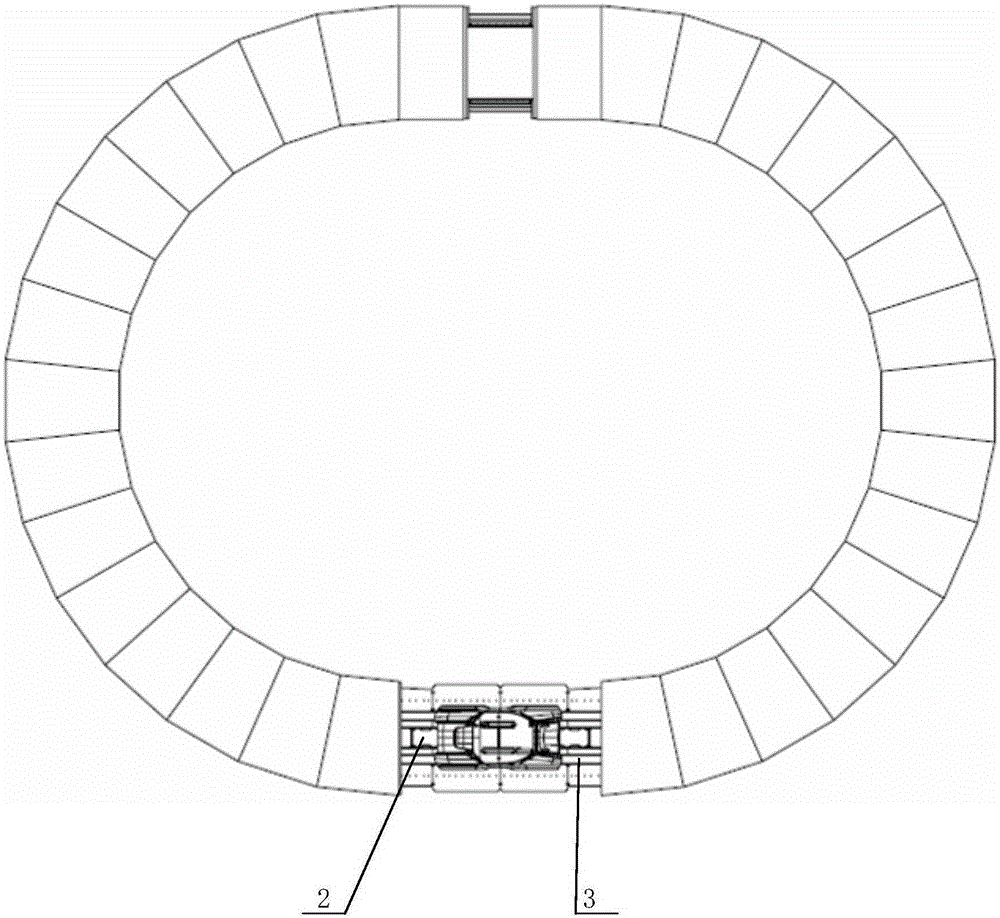

[0012] Such as figure 1 and figure 2 As shown, the present invention includes a vacuum pipeline 1, a linear motor 2, a maglev track 3, a maglev vehicle 4, and the like. The test line is to arrange the linear motor 2, the maglev track 3 and the maglev vehicle 4 inside the vacuum pipeline (1), realizing the combination of the superconducting maglev vehicle and the vacuum pipeline circuit.

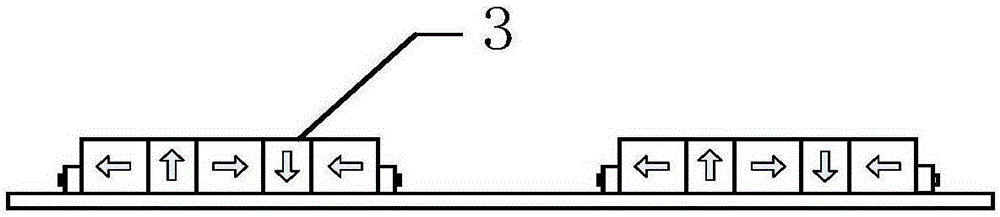

[0013] In a specific embodiment, such as image 3 The maglev track 3 shown is set inside the vacuum pipeline 1. The track is a double-track parallel structure and is composed of a Halbach-type neodymium-iron-boron magnet array. The magnetic field provided by the track can make the high-temperature superconducting maglev vehicle run stably.

[0014] The linear motor 2 is responsible for driving / braking the maglev vehicle. It has the characteristics of low noise and high operation stability, and can realize non-contact operation control, which effectively improves the high-speed reliability ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com