Auxiliary supporting rod assembly special for prefabricated panel with door opening

A technology of auxiliary support rods and prefabricated wall panels, which is applied in the direction of special packaging objects, external frames, packaging of vulnerable items, etc., can solve the problems of increasing the weight of on-site hoisting and work difficulty, waste of reinforced concrete, and affecting the construction progress, etc., to achieve Low cost, save mold cost and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

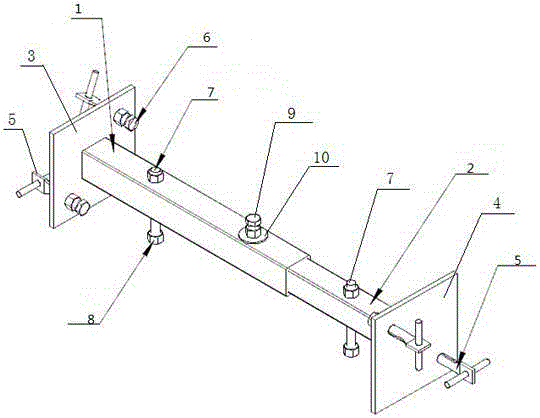

[0022] see figure 1 , the special auxiliary support rod assembly for prefabricated wall panels with door openings of the present invention includes a large square tube, a small square tube with one end inserted into the large square tube, a steel plate A welded to one end of the large square tube and a steel plate B welded to one end of the small square tube, A number of screw holes are drilled on the steel plate A and the steel plate B, and a sleeve is fixed with a screw in each screw hole, and the sleeve is pre-buried in the prefabricated wall panel with a door opening, and the overlapping section of the large square tube and the small square tube The connection and positioning are fixed by bolts and nuts.

[0023] The specific implementation of the present invention will be further described below in conjunction with accompanying drawing:

[0024] The present invention uses square tubes of two sizes to ensure that the small square tube can be inserted into the inner hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com