sludge storage tank

A technology for storage tanks and sludge, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of sludge storage tanks losing mud-scraping performance and maintenance difficulties, achieving obvious energy-saving effects, good sludge discharge effects, and preventing sludge The effect of accumulation of mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

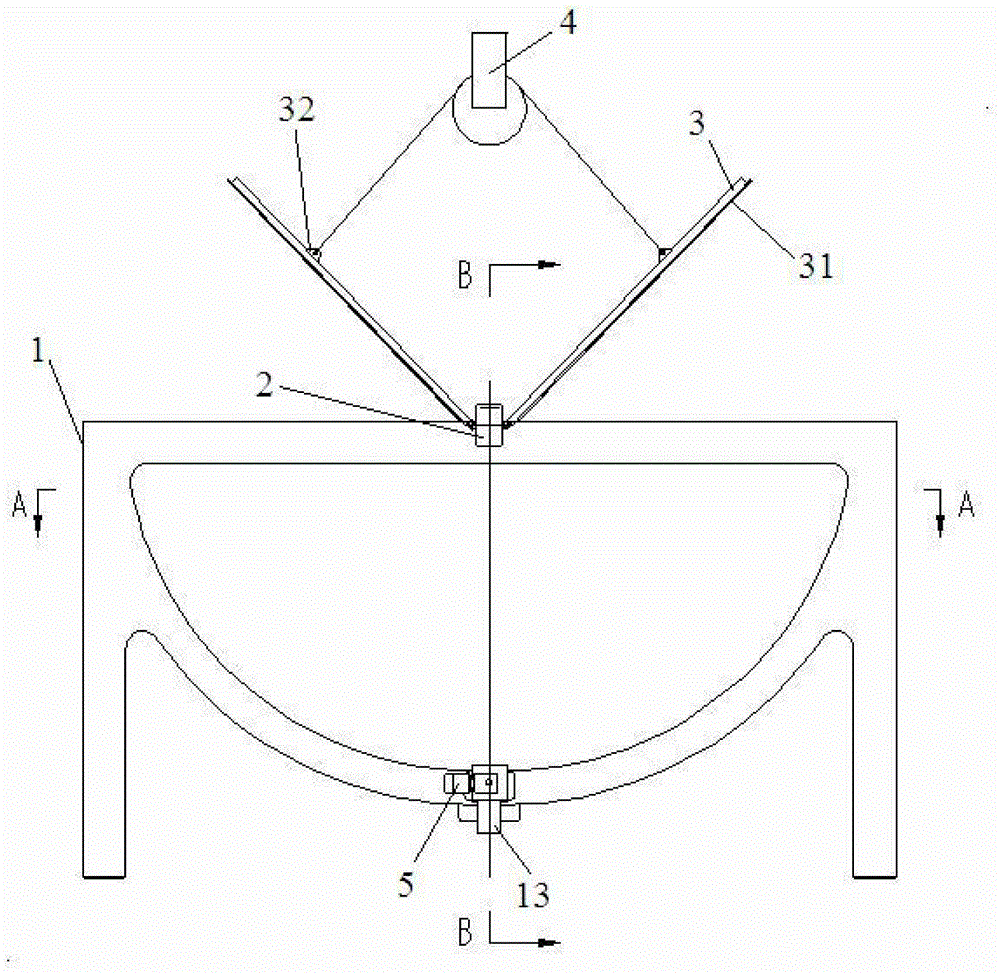

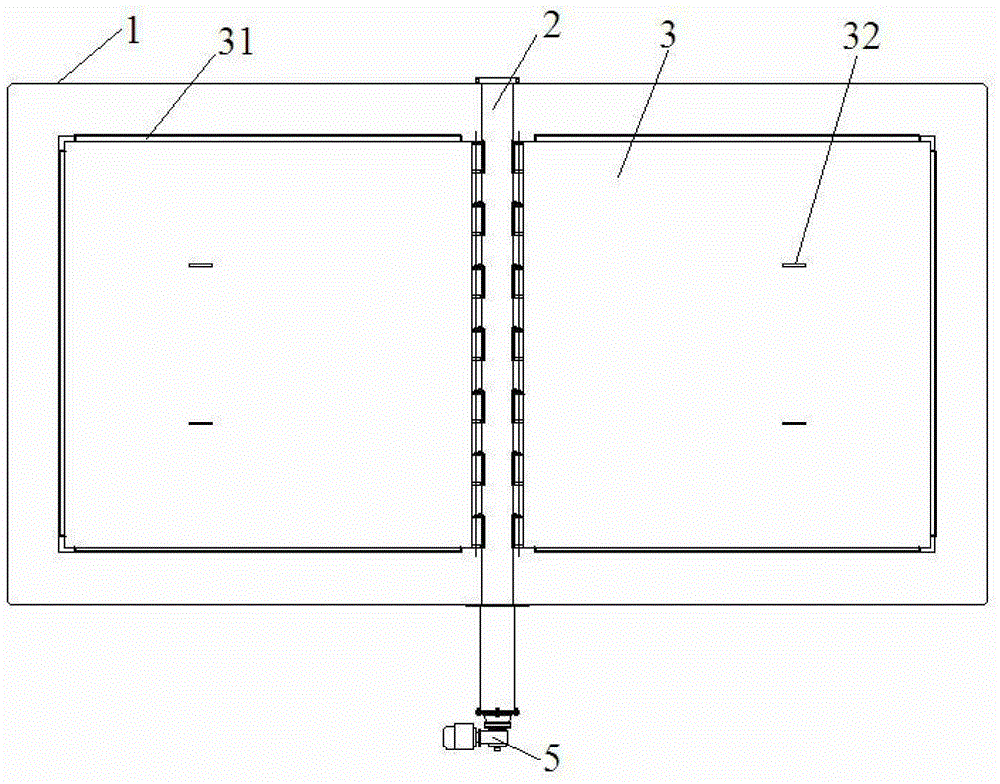

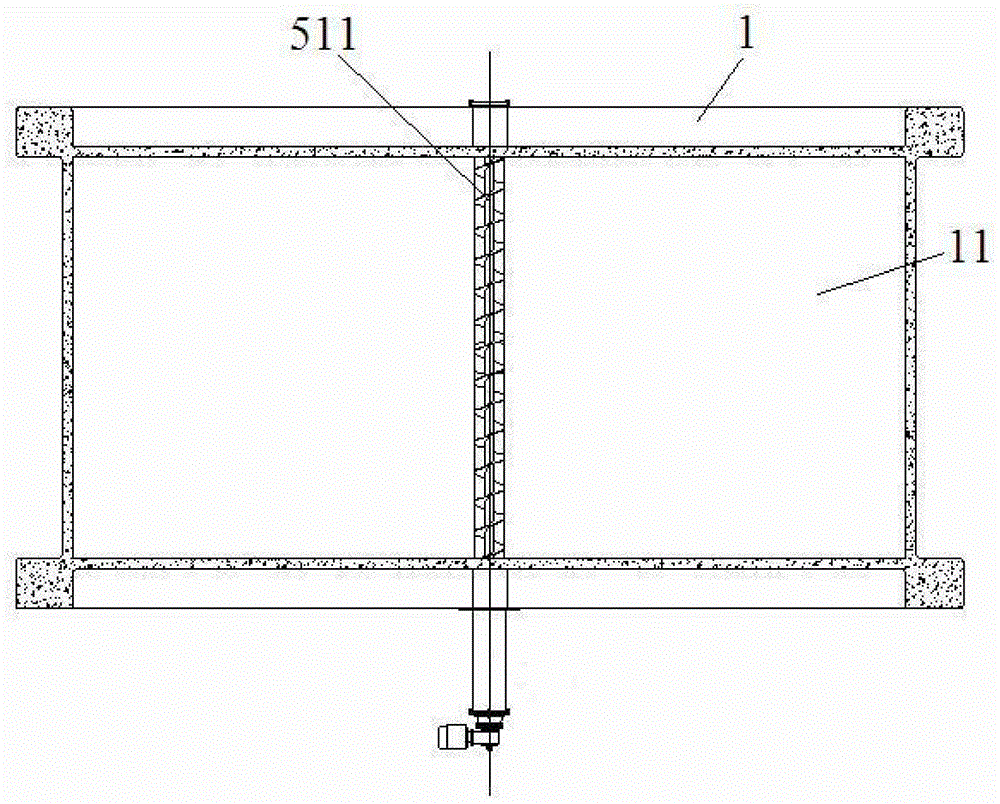

[0027] see Figure 1 ~ Figure 3 The sludge storage tank includes a tank body 1, a beam 2, a tank cover 3, a lifting device 4, and a sludge discharge device 5. The bottom surface of the tank body 1 is a horizontal cylindrical surface, and the sides of the tank body 1 are located at both axial ends of the tank body. And the sides of the axial ends of the pool body are planes, the top of the pool body 1 is provided with a feed port 11 along the horizontal axial section, the beam 2 is fixed on the feed port 11 at the top of the pool body 1 along the axial direction, and the beam 2 is movable and hinged There is a pool cover 3, the edge of the pool cover 3 is attached to the inner wall of the pool body 1, a lifting device 4 for lifting and opening and closing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com