Sand plating solution device on diamond cutting line

A technology of diamond cutting wire and plating solution, which is applied in the direction of electrolytic coating, coating, etc., can solve the problems of high waste wire rate, affect product quality, and reduce work efficiency, so as to reduce production costs, solve uneven sanding, and improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

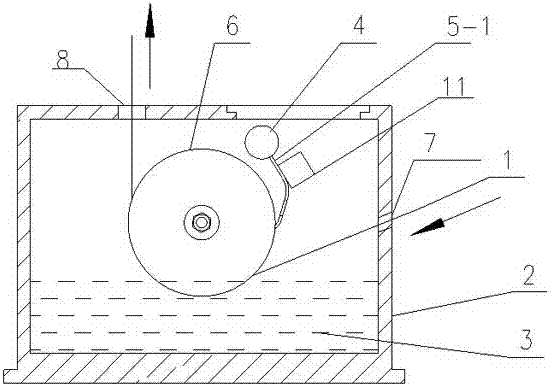

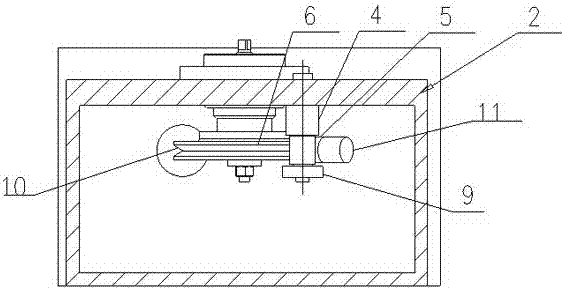

[0025] Embodiment 1: sand plating solution device on the diamond cutting line, such as figure 1 and figure 2 As shown, including the effusion box 2, the side wall of the effusion box 2 is provided with an inlet hole 7, the upper part of the effusion box 2 is provided with an outlet hole 8, and the side wall of the effusion box 2 is provided with a lead wheel 6, and the lead wire The wheel 6 is provided with a V-shaped groove 10 for the diamond cutting wire 1 to pass through, and a cleaning device is provided on the side wall of the liquid accumulation tank 2. The cleaning device is located on the side of the wire wheel 6 in the direction of the diamond cutting wire 1. Cleaning The device includes a scraper 5-1 and a fixed shaft 4, one end of the fixed shaft 4 is arranged on the side wall of the liquid accumulation tank 2, the lead wheel 6 and the fixed shaft 4 are arranged on the same side wall of the liquid accumulation tank 2, and the scraper 5-1 The upper end is connected...

Embodiment 2

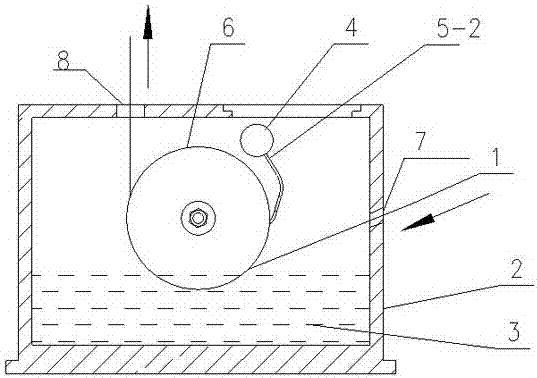

[0027] Embodiment 2: sand plating solution device on the diamond cutting line, such as image 3 As shown, the scraper 5-2 is an elastic plate, and the others are the same as in Embodiment 1.

[0028] Working process: fine-tune the lead wheel 6 first, and then apply sand plating solution.

[0029] The process of fine-tuning the lead wheel 6 to the left and right along the long hole: unscrew the fastening screw 18, and adjust the bearing sleeve assembly 12 to the left and right along the long hole 15, so that the bearing sleeve assembly 12 and the screw shaft 13 reach the appropriate position on the liquid accumulation tank 2, That is to ensure that the bottom of the lead wheel 6 can be centered with the center of the outlet hole 8 left and right, and the fastening screw 18 can be tightened; Lead wire wheel 6 to the suitable position on screw shaft 13, guarantee that the V-shaped groove bottom of lead wire wheel 6 can be centered front and back with outlet hole 8 center, tighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com