Dyeing process for acidic fluorescent dye

A fluorescent dye and process technology, applied in the field of acid fluorescent dye dyeing process, can solve the problems of poor dyeing reproducibility, dye uptake rate, inconsistent stability, poor color reproducibility in large-scale production, etc., to improve reproducibility, Avoid uneven dyeing and slow down the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 fluorescent light pink

[0030]Fabric: brocade + spandex warp knitted fabric, width 141cm, weight 155g / m 2

[0031] Equipment: Yaji AK-DSL dyeing vat, Datacolor color measuring and matching instrument, pH meter

[0032] The dyeing formula is as follows:

[0033]

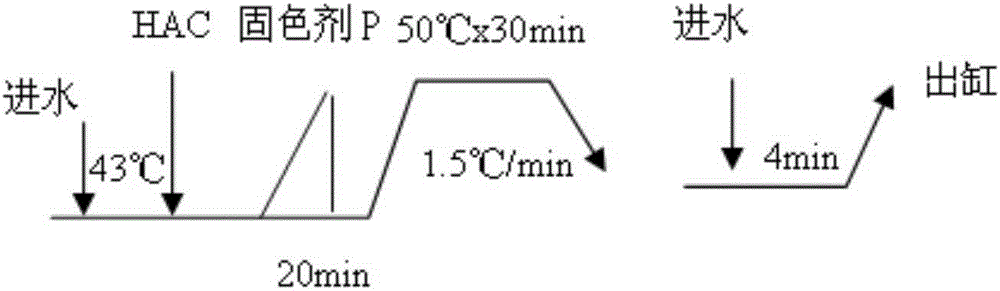

[0034] The fixation formula is as follows:

[0035] Powf% (Demei Chemical) 5.0

[0036] HAC(g / L)0.3

[0037] Bath ratio 1:5

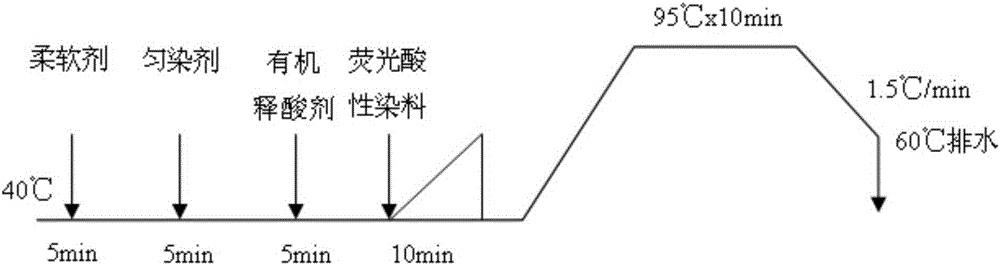

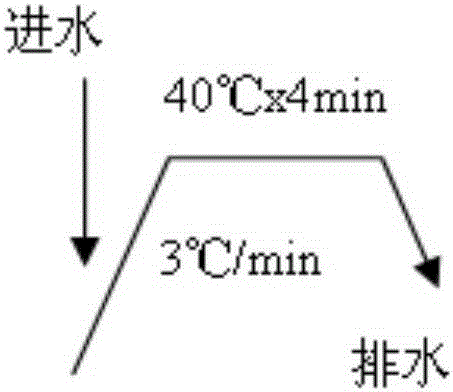

[0038] Put the fabric in the AK-DSL dye vat, add softener according to the above formula at 40°C, add leveling agent after stirring for 5 minutes, add organic acid release agent VS after stirring for 5 minutes, add NylosanE8G1 yellow and and NylosanB red (control linear addition time is 10min), heat up to 100°C at a rate of 0.8°C / min and keep warm for 25min, then cool down to 60°C at a rate of 1.5°C / min to drain water; Wash, heat up to 40°C at a rate of 3°C / min and keep warm for 4 minutes, drain; at 43°C, add water and acetic acid into the Then dyeing air machine acc...

Embodiment 2

[0041] Example 2 Fluorescent medium purple

[0042] Fabric and equipment are all identical with embodiment 1.

[0043] The dyeing formula is as follows:

[0044]

[0045] Color fixing formula is identical with embodiment 1.

[0046] According to the above formula, the fluorescent medium purple fabric was prepared by the same dyeing process as in Example 1, wherein the dyeing heating rate was 1.0° C. / min.

Embodiment 3

[0049] Embodiment 3 fluorescent brilliant red

[0050] Fabric and equipment are all identical with embodiment 1.

[0051] The dyeing formula is as follows:

[0052]

[0053]

[0054] Color fixing formula is identical with embodiment 1.

[0055] According to the above formula, fluorescent bright red fabric was prepared by the same dyeing process as in Example 1, wherein the dyeing heating rate was 1.5° C. / min. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com