Projection Calibration System of Machine Vision Detection System for Vehicle-mounted Pavement Cracks

A technology of machine vision detection and calibration system, applied in the direction of roads, roads, road repairs, etc., to achieve the effect of ensuring accuracy, comprehensive functions, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

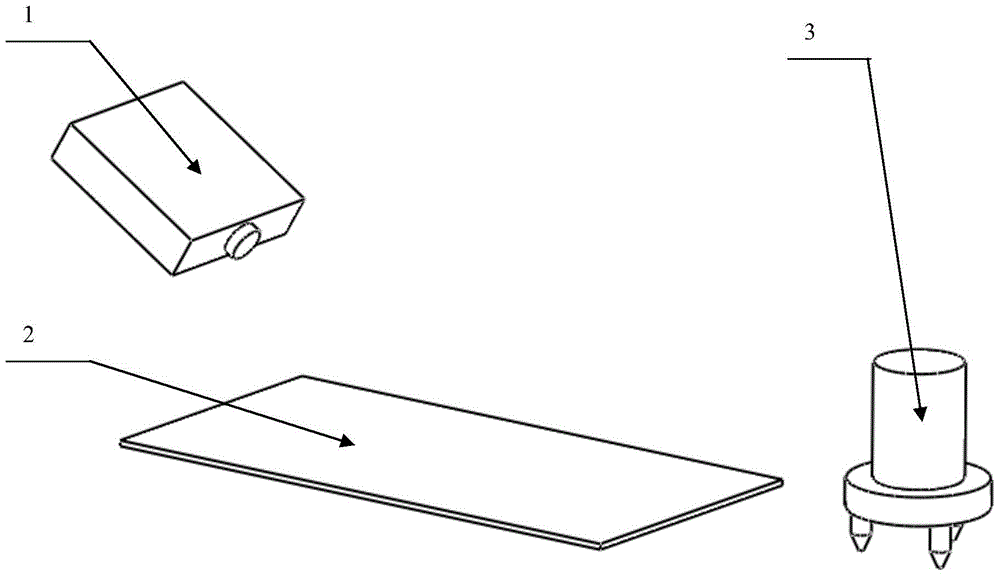

[0017] refer to figure 1 , the projection calibration system of the vehicle-mounted road surface crack machine vision detection system includes a projector 1 , a receiving board 2 and a level 3 .

[0018] The level 3 is a laser line level, and the level 3 is placed horizontally on the ground.

[0019] The receiving plate 2 is a cuboid part processed from a steel plate, and the surface of the receiving plate 2 is processed into a diffuse reflection surface, and the upper surface of the receiving plate 2 coincides with the horizontal laser reference plane of the level 3 .

[0020] The projector 1 is a general-purpose projector, and the projector 1 is placed obliquely downward on the receiving board 2 , and the projector 1 projects a standard road surface picture on the upper surface of the receiving board 2 .

[0021] How to use the projection calibration system of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com