A method and device for railway bridge maintenance detection around bridge piers

A bridge pier and railway technology, which is applied in the field of railway bridge maintenance detection methods and devices, can solve problems such as the inability to realize cross-bridge pier detection box maintenance, and achieve the effect of high operating efficiency and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

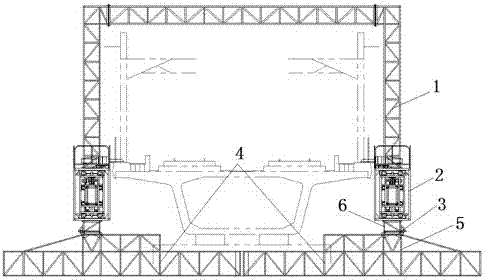

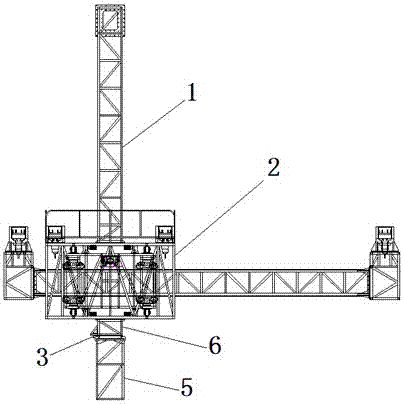

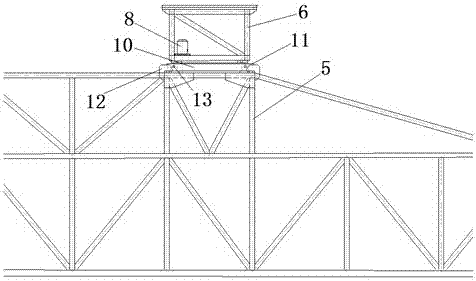

[0049] by attaching figure 1 and 2 It can be seen that the present invention relates to a bridge pier maintenance and detection operation device for railway bridges, which includes a portal frame 1 connected with a horizontal truss and shaft trusses on both sides, a main frame 2 is suspended under the portal frame, and the main frames 2 on both sides are lowered. The slewing mechanism 3 and the maintenance and inspection work platform 4 are respectively connected, and it is characterized in that the maintenance and inspection work platform 4 is a two-stage cantilever structure, and the maintenance and inspection work platform 4 is divided into two sections, which are hung on the main frames on both sides respectively. 2, and can be rotated relative to the main frame 2 to form a two-part rotatable operating arm 5. When the rotatable operating arm 5 passes through the bridge pier, it rotates around the bridge pier to realize maintenance and testing around the bridge pier under t...

Embodiment 2

[0053] The structure of the second embodiment is basically the same as that of the first embodiment. It is a railway bridge around the pier maintenance inspection device, including the gantry connected by the horizontal truss and the shaft truss on both sides. A main frame is suspended under the gantry, and the main A slewing mechanism and a maintenance and inspection work platform are respectively connected under the frame. It is characterized in that the maintenance and inspection work platform is a two-stage cantilever structure, and the maintenance and inspection work platform is divided into two sections, which are respectively hung under the main frames on both sides. And it can rotate relative to the main frame to form a two-part rotatable operating arm. When the rotatable operating arm passes through the bridge pier, it can rotate around the bridge pier to realize the maintenance and inspection work around the bridge pier under the bridge.

[0054] It’s just that the sl...

Embodiment 3

[0056] Embodiment 3 has basically the same structure as Embodiment 1. It is a railway bridge pier-wrapping operation device for repairing and testing around pier, which includes a gantry connected by horizontal trusses and shaft trusses on both sides. A main frame is suspended under the gantry, and the main A slewing mechanism and a maintenance and inspection work platform are respectively connected under the frame. It is characterized in that the maintenance and inspection work platform is a two-stage cantilever structure, and the maintenance and inspection work platform is divided into two sections, which are respectively hung under the main frames on both sides. And it can rotate relative to the main frame to form a two-part rotatable operating arm. When the rotatable operating arm passes through the bridge pier, it can rotate around the bridge pier to realize the maintenance and inspection work around the bridge pier under the bridge.

[0057] It’s just that the slewing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com