Connection joint between endplate type concrete-filled steel tube column and steel beam with internal reinforcement ring

A technology of concrete filled steel tubular columns and inner reinforcement rings, applied in the directions of columns, joists, girders, etc., can solve the problems of difficult construction of high-strength bolts, and achieve the effects of superior hysteretic performance, good seismic performance, and reduced complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

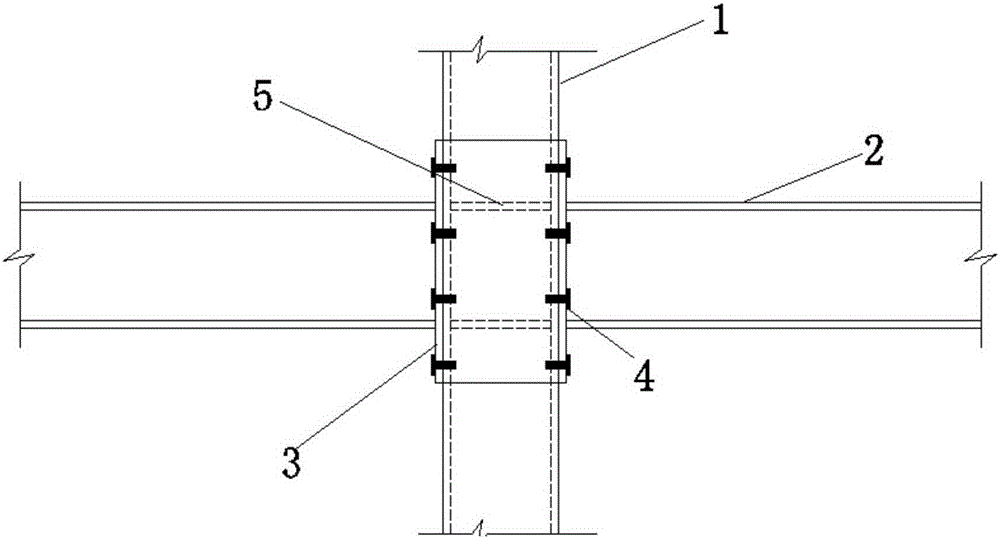

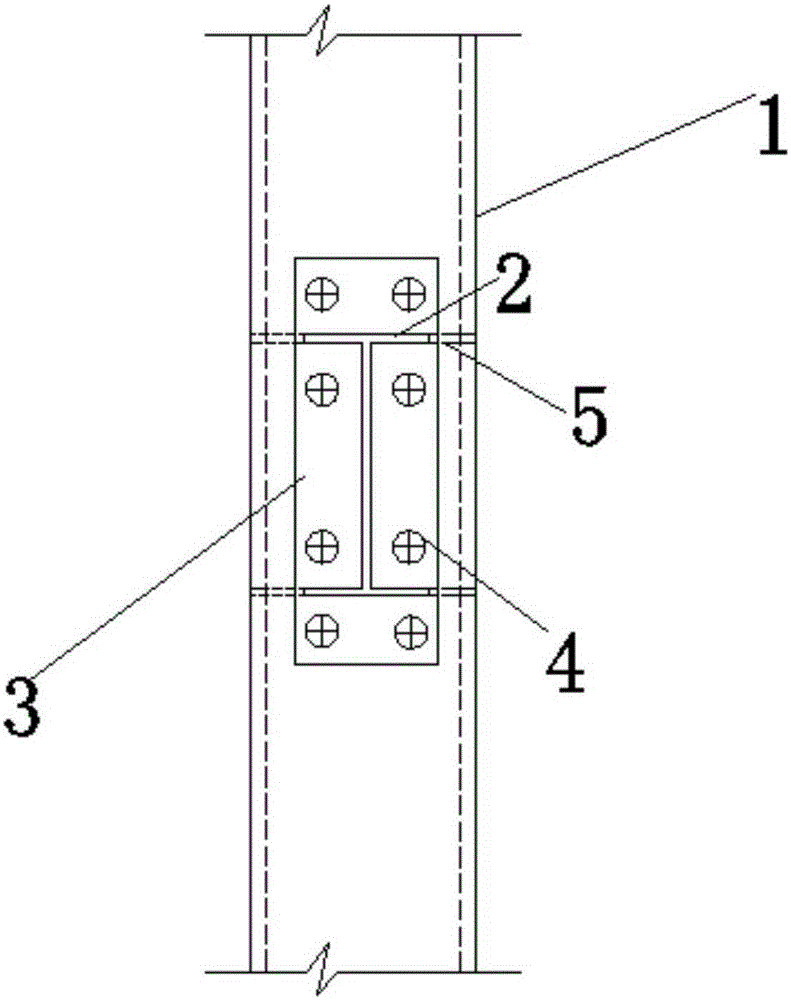

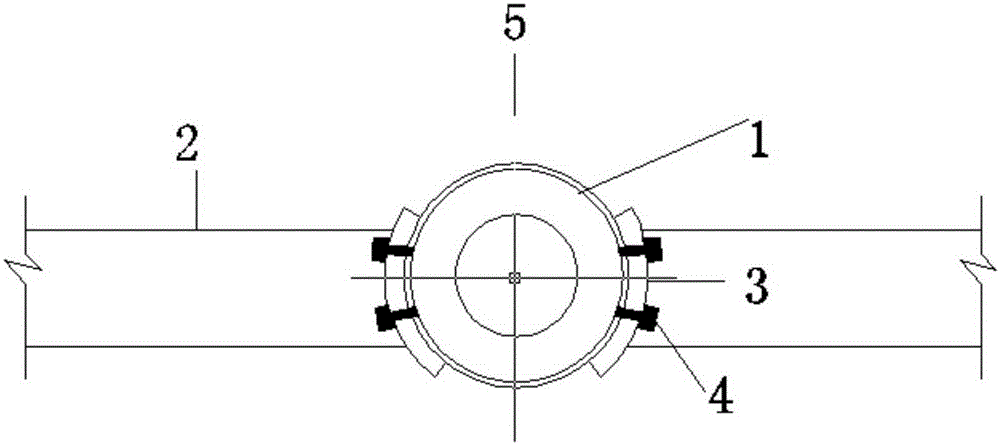

[0020] A connection node between an end-plate concrete-filled steel pipe column and a steel beam with an inner reinforcing ring, comprising: a circular concrete-filled steel pipe column 1, a steel beam 2, an end plate 3, a single-side self-tightening bolt 4, and an inner reinforcing ring 5, wherein:

[0021] Two internal reinforcement rings 5 are welded on the inner side of the steel tube column wall of the circular steel tube concrete column, and its position corresponds to the upper and lower flanges of the steel beam 2 connected to the steel tube column wall; the end of the steel beam 2 is welded on the end plate 3 The concrete-filled steel tube column wall 1 and the end plate 3 are correspondingly opened with 4 rows and 2 columns of bolt holes; the unilateral bolt 4 passes through the bolt holes reserved for the end plate 3 and the steel tube wall of the round concrete-filled steel tube column 1 from the outside to the inside. The end plate is connected with the circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com