Electric hydraulic ring-plug pump

A technology of electro-hydraulic pumps and ring plugs, which is applied in the direction of pumps, multi-cylinder pumps, pump components, etc., can solve the problems of low frequency response of direct-drive volume control systems, and achieve the effects of light weight, cost reduction, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

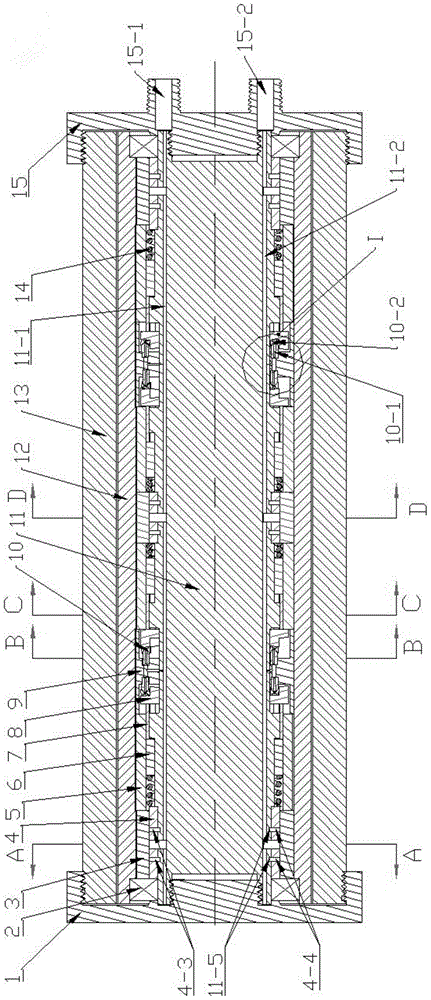

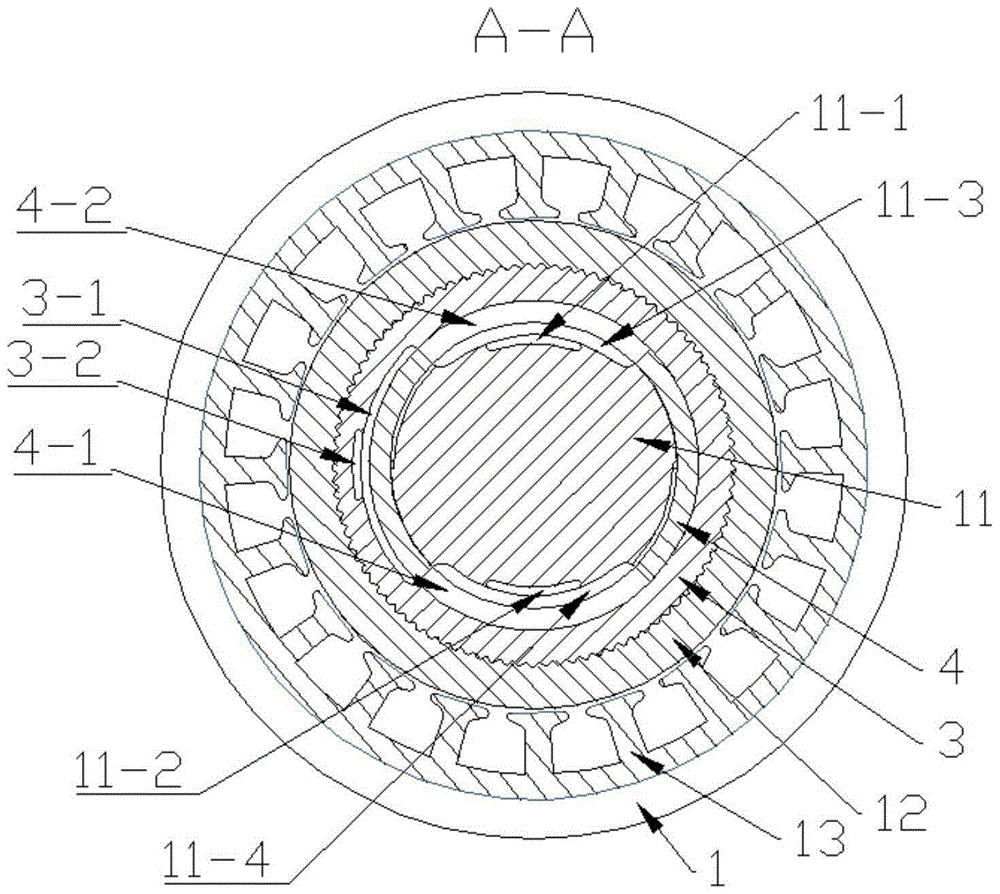

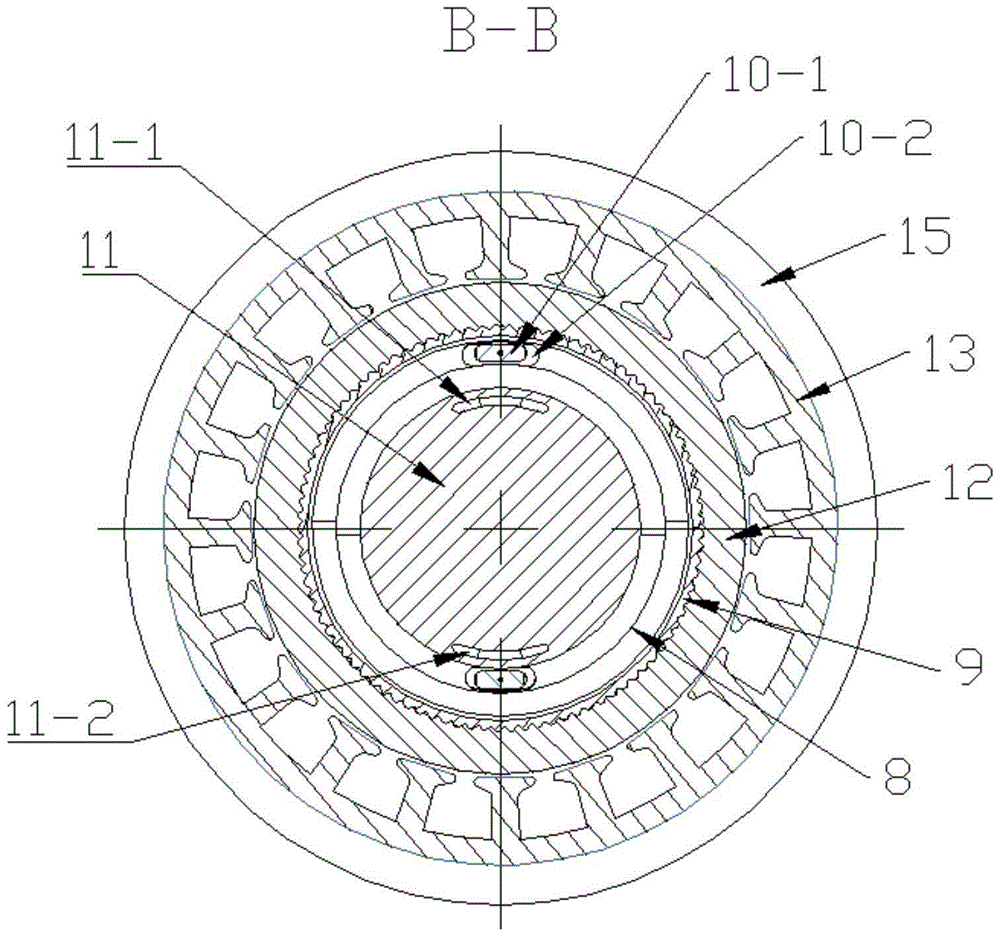

[0014] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the technical solution of this specific embodiment is illustrated, which includes a sealing end cover 1, two bearings 2, three oil distribution rings 3, three oil distribution sleeves 4, four ring plug sleeves 5, and four ring plugs 6 , four guide rings 7, four swash plates 8, two drive rings 9, eight sets of shoe ejector rod mechanisms 10, hydraulic pump stator 11, motor rotor 12, motor stator 13, spring 14, interface end cover 15;

[0015] Each shoe ejector mechanism 10 is formed by the ejector rod 10-1 connected to the shoe 10-2; the hydraulic pump stator 11 is sequentially covered with a bearing 2, an oil distribution sleeve 4, a Spring 14, a ring plug 6, a guide ring 7, a swash plate 8, a drive ring 9, a swash plate 8, a guide ring 7, a ring plug 6, a spring 14, an oil distribution sleeve 4, a spring 14. A ring plug 6, a guide ring 7, a sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com