Pressurization device for adherence and solidification of low-temperature test strainometer of large storage tank

A low-temperature test and pressurization device technology, applied in the field of strain test, can solve the problems of small number of measuring points, single structure, and inability to meet large-scale storage tank tests, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be further described in conjunction with the drawings and specific embodiments.

[0026] The pressurizing device for pasting and curing strain gauges for low-temperature tests in large storage tanks is a necessary equipment in the process of pasting strain gauges for low-temperature tests in liquid hydrogen temperature zones. This subject explores a set of strain gauges suitable for low-temperature tests for large storage tanks through research on these technologies. The design and application route of the pressure device for pasting and curing lays the foundation for the low-temperature test of large-scale low-temperature storage tanks.

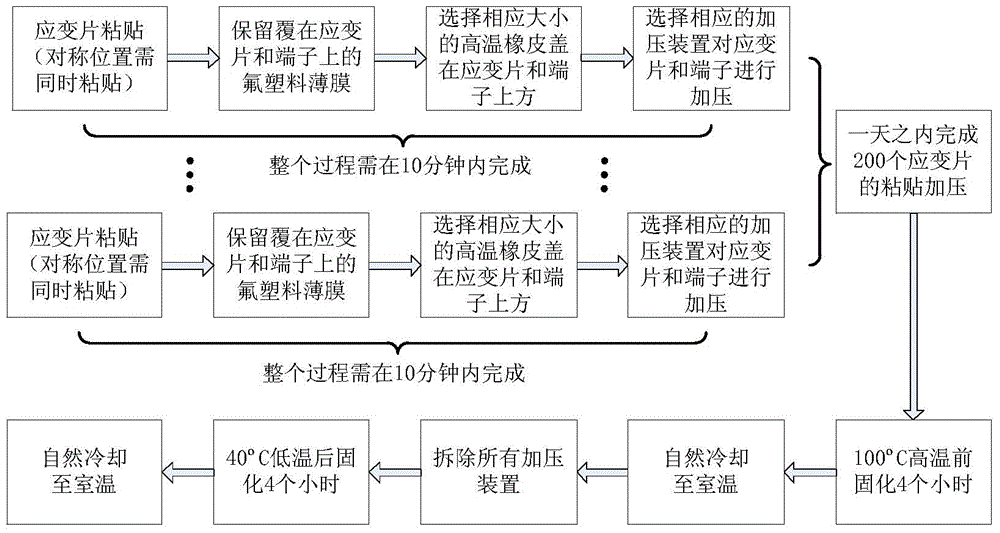

[0027] In the design process of the pressurizing device for pasting and curing of the large storage tank low temperature test strain gauge to which the present invention belongs, the following steps have been carried out:

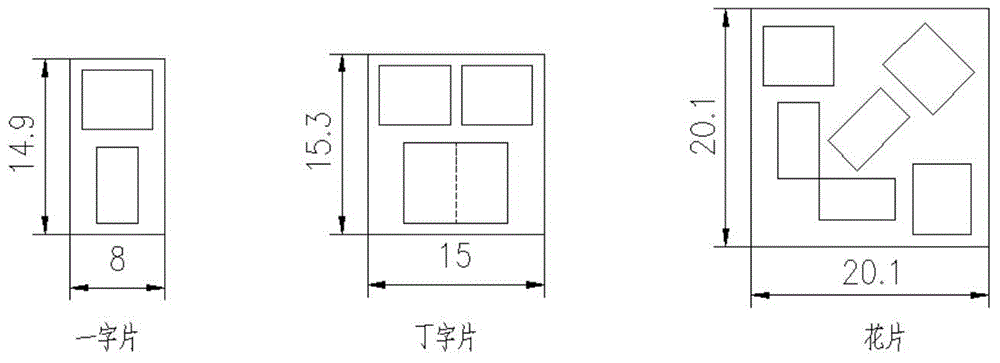

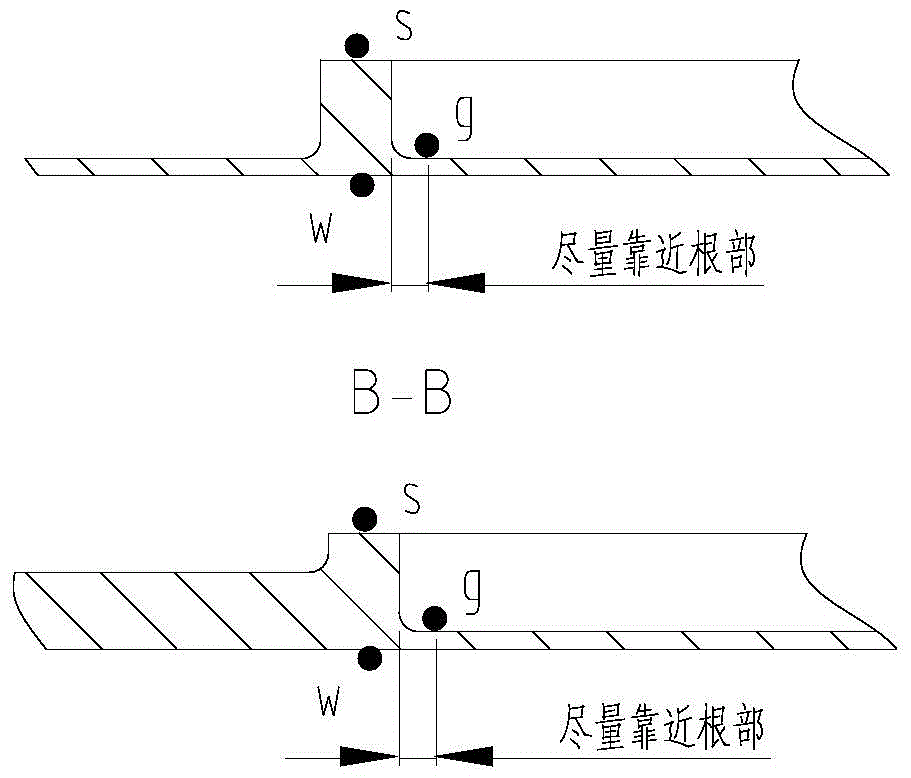

[0028] a) Research on the sticking process of low temperature strain gau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com