Pressure wave supercharging auxiliary twin-stage vapor compression refrigeration system and working method thereof

A technology of compressing refrigeration and steam, applied in refrigerators, compressors, refrigeration and liquefaction, etc., can solve the problems that hinder the wide application of R718 refrigerant and the high initial investment of inter-stage cooling equipment, and achieve excellent operating performance with liquid, excellent belt performance. Liquid handling performance, the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 A four-port wave rotor booster is used to assist boosting a two-stage vapor compression refrigeration system.

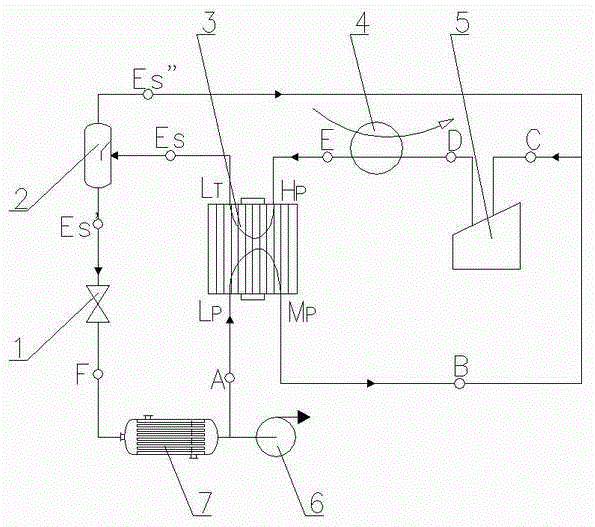

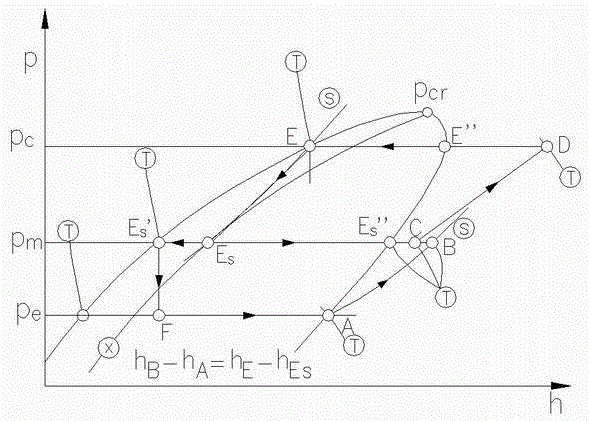

[0020] figure 1 A two-stage vapor compression refrigeration system assisted by air wave supercharging is shown. In the figure, the two-stage vapor compression refrigeration system assisted by a four-port wave rotor supercharger includes a throttle valve 1, a gas-liquid separator 2, a four-port wave rotor supercharger 3, a condenser 4, a vapor compressor 5, Vacuum pump 6, evaporator 7. The outlet of the evaporator 7 and the low-pressure steam inlet L of the four-port wave rotor supercharger 3 P Connection, boost steam outlet M of four-port wave rotor turbocharger 3 P Adopt pipeline to be connected with the inlet of refrigerating compressor 5, the gas phase outlet of gas-liquid separator 2 also adopts pipeline to be connected with the inlet of refrigerating compressor 5; The outlet pipe and the drive fluid inlet H of the four-port wave rotor supe...

Embodiment 2

[0023] Example 2 A two-stage vapor compression heat pump system is assisted by a four-port wave rotor supercharger.

[0024] In principle, the process and equipment layout remain unchanged, and the evaporator is used to absorb heat from the environment to obtain the heat of the condenser, and a four-port wave rotor supercharger can be used to assist the supercharged two-stage vapor compression heat pump system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com