Nanopore silicon insulation board for kiln

An insulation board and nano-hole technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of no high-temperature thermal radiation protection function, poor thermal insulation effect, and high radiation heat loss, and achieve good overall structural strength. Good cushioning performance and the effect of improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

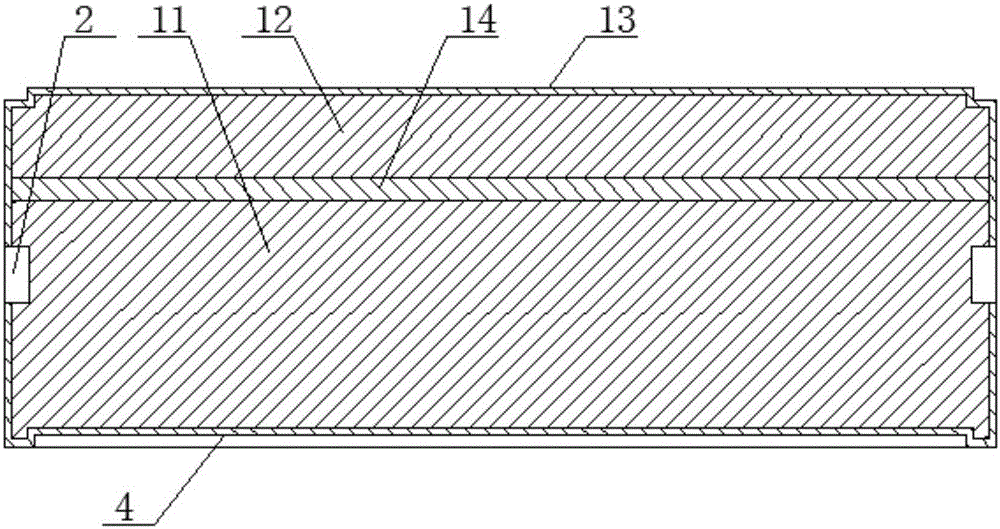

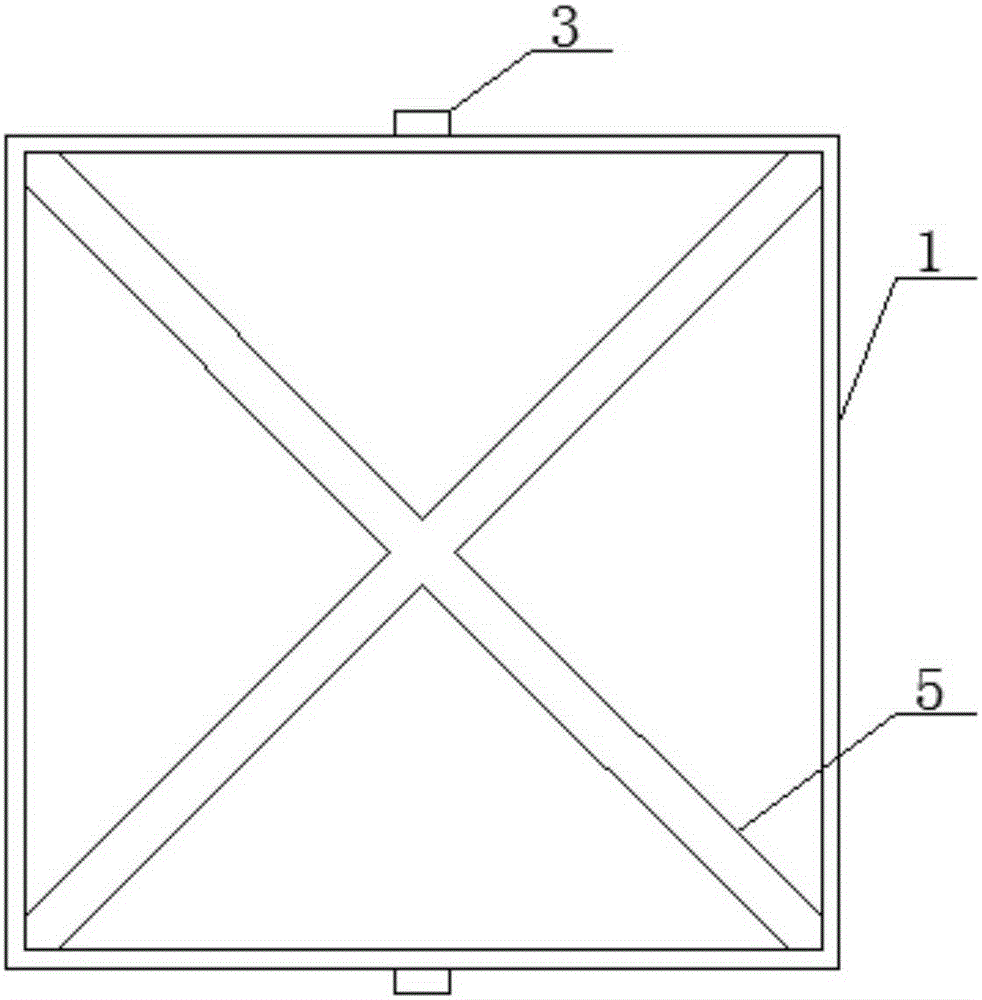

[0014] Such as figure 1 with figure 2 Shown, a kind of kiln nanoporous silicon thermal insulation board comprises thermal insulation layer 11, thermal insulation buffer layer 12 and radiation protection layer 13, and described thermal insulation buffer layer 12 is bonded on the upper layer of thermal insulation layer 11 by adhesive 14, and described The radiation protection layer 13 wraps the thermal insulation layer 11 and the thermal insulation buffer layer 12 through an adhesive 14 to form a thermal insulation board 1 with a cross-sectional shape of a "convex" structure. The thermal insulation layer 11 is specifically a nanoporous silicon material thermal insulation layer, so The anti-radiation layer 13 is specifically an aluminum foil cloth ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap