Liquid level detection method and liquid level detection device based on visible laser and image processing

A technology of liquid level detection and image processing, which is applied in the field of liquid level detection and devices based on visible laser and image processing, and can solve problems such as difficulty in liquid level line extraction, insufficient anti-interference ability, and detection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

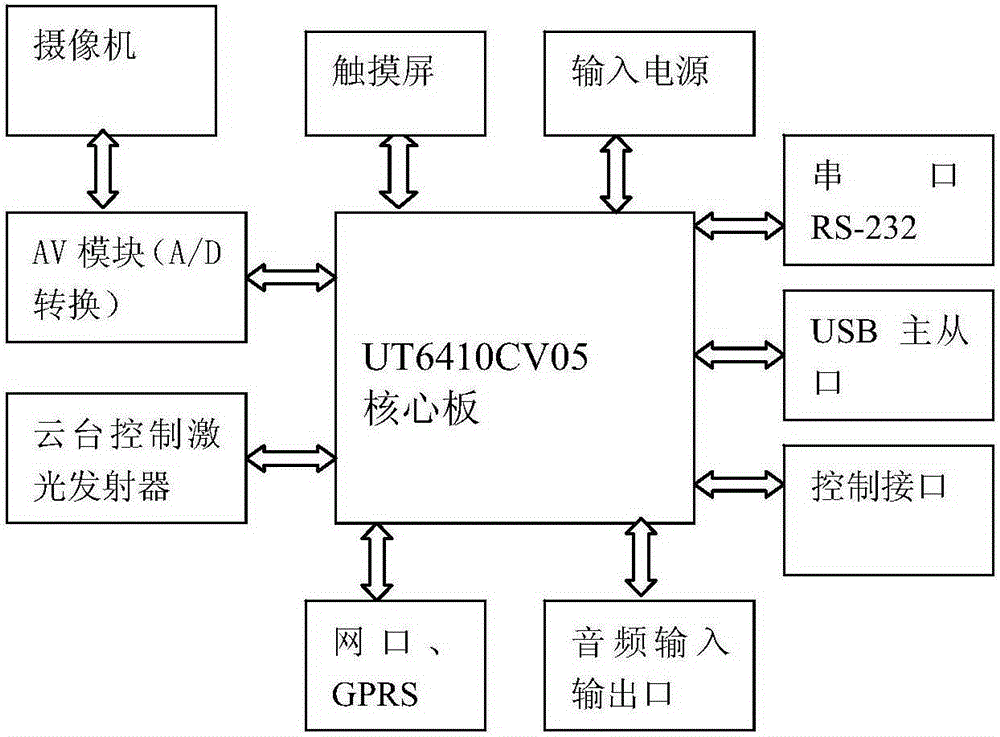

[0079] A liquid level detection method based on visible laser and image processing, including the following steps:

[0080] Step 1: Establish a measurement coordinate system;

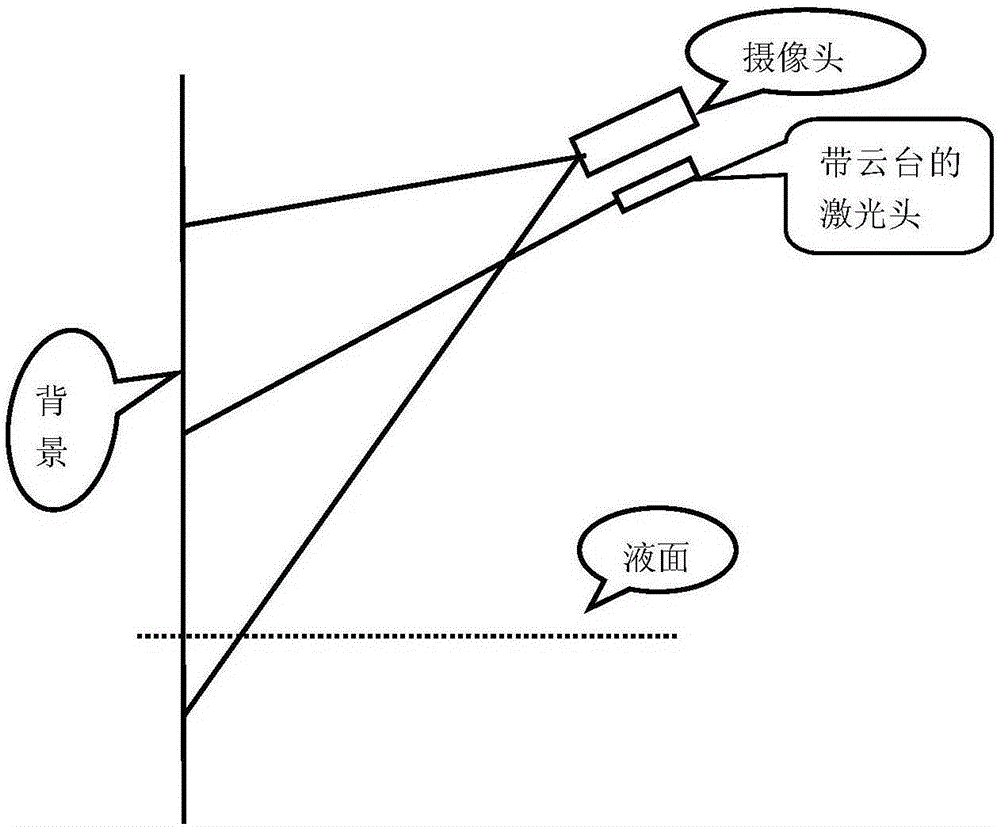

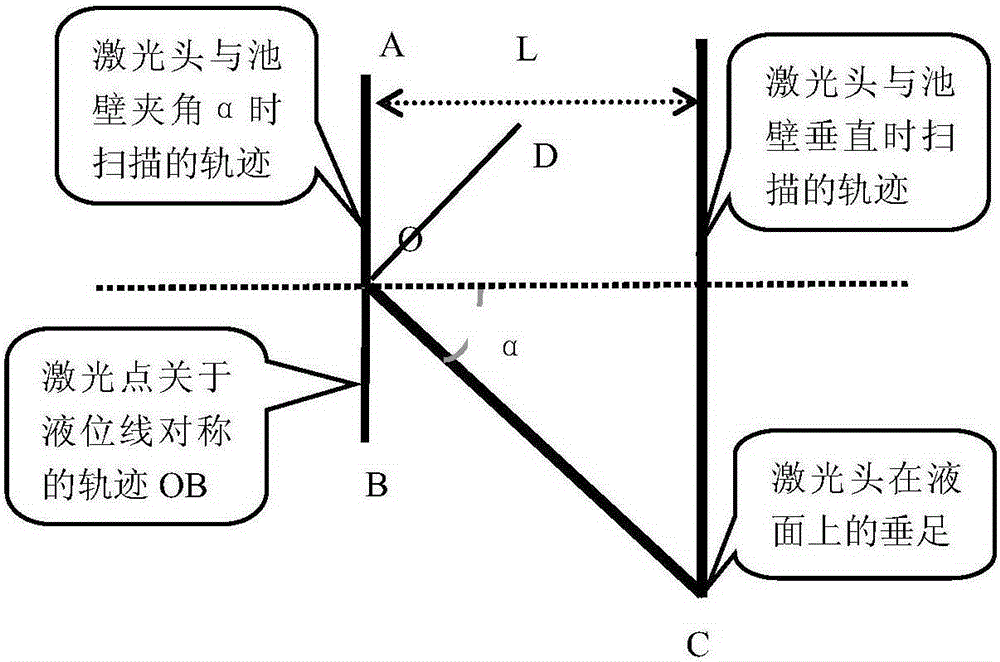

[0081] Establish the one-dimensional coordinate AB" of the liquid level used to characterize the actual liquid level change along the vertical direction; the one-dimensional coordinate AB" is located in the plane where the background is located; the background is the vertical inner wall of the container for storing the liquid;

[0082] The camera and the laser head for emitting visible laser light are set above the liquid surface; the camera faces the background obliquely downward relative to the horizontal plane; the angle between the optical axis of the camera and the horizontal plane is θ;

[0083] Establish the projected one-dimensional coordinate AB, and the angle between the projected one-dimensional coordinate AB and the one-dimensional coordinate AB″ of the liquid level is θ;

[0084] Remember that the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com