Manufacturing method of touch screen with IR induction zone

A manufacturing method and technology of the sensing area, which are applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of easy wrinkles on the IR ink layer, high manufacturing cost of the touch screen, and insufficient printing accuracy. The effect of saving IR ink, reducing the production process, and reducing the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

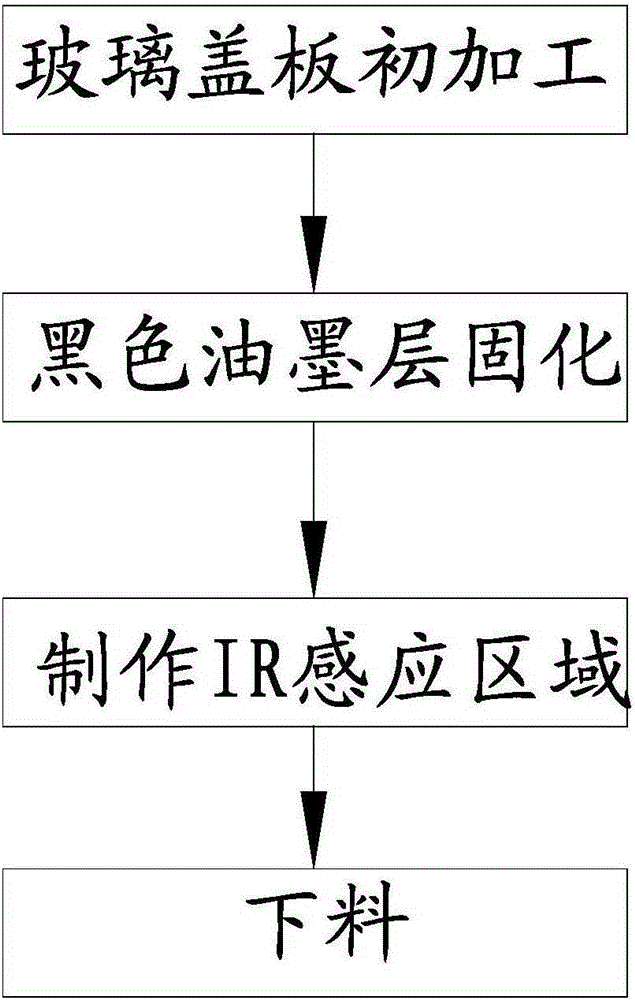

[0027] Such as figure 1 As shown, the manufacturing method of the touch screen with the IR sensing area has the following steps:

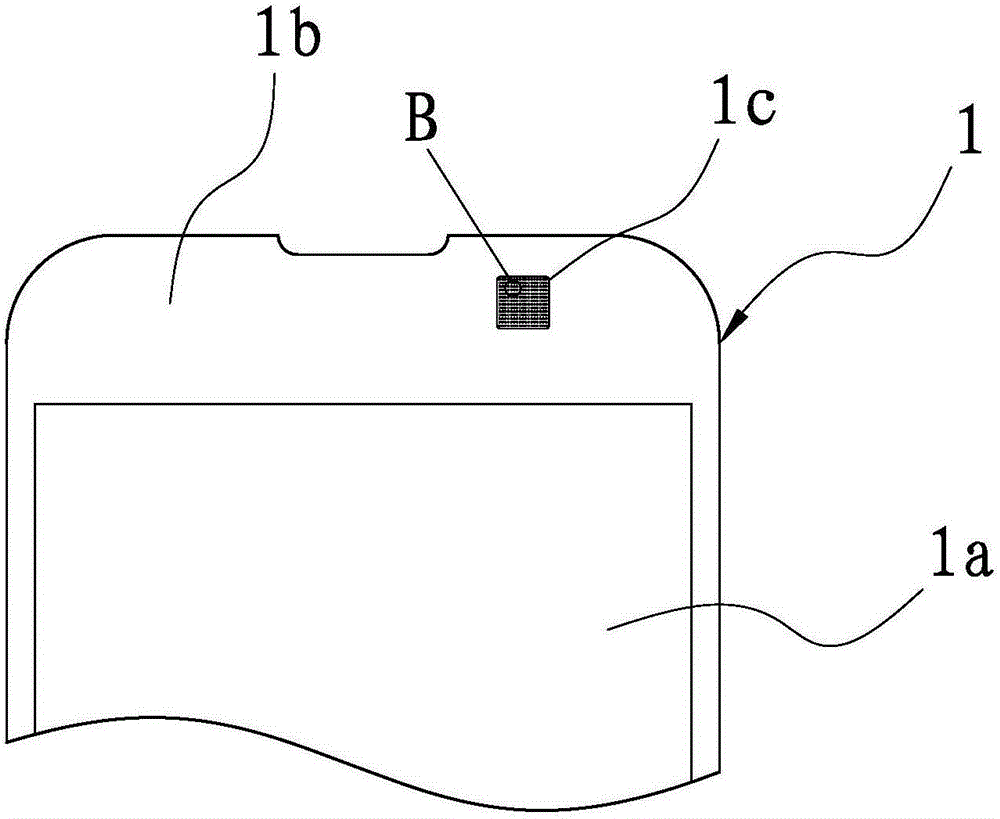

[0028] A. Initial processing of the glass cover: select the glass cover 1, which has a front and a back, and design a display area 1a and a non-display area 1b on the back of the glass cover 1. The display area 1a is mainly used for various applications on mobile phones In the information display window, the non-display area 1b is mainly used as a frame area, and a black ink layer 1d is attached to the non-display area 1b on the reverse side of the glass cover 1 . Normally, the black ink layer 1d is one layer. In this step, after the glass cover 1 is selected, the glass cover 1 needs to be cut into the size of a mobile phone, and the glass cover 1 needs to be cleaned and dried before cutting, so that the surface of the glass cover 1 can remove dust and other impurities to improve the quality of finished products. It should be noted that the blac...

Embodiment 2

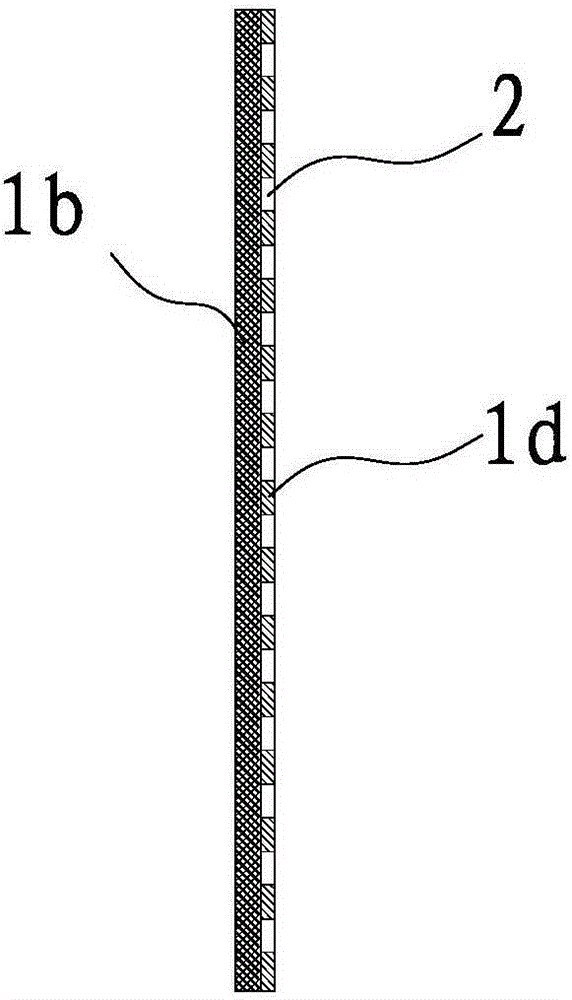

[0037] In this embodiment, the manufacturing method of the touch screen with the IR sensing area is the same as that in Embodiment 1, the difference lies in the design of the IR sensing area 1c, specifically: the area of the IR sensing area 1c is 30mm*100mm, laser engraving Specifically, it includes engraving a number of circular light-transmitting small holes 2 on the black ink layer 1d of the IR sensing area 1c, and the number of light-transmitting small holes 2 satisfy the following mathematical model: In the formula, a is the hole spacing in the horizontal direction, taking a value of 0.03mm; b is the hole spacing in the vertical direction, taking a value of 0.05mm; d is the hole diameter, taking a value of 0.03mm; T is the transmittance, taking The value is 17.1%, and its allowable error is ±0.1%.

Embodiment 3

[0039] In this embodiment, the manufacturing method of the touch screen with the IR sensing area is the same as that in Embodiment 1, the difference lies in the design of the IR sensing area 1c, specifically: the area of the IR sensing area 1c is 50mm*60mm, laser engraving Specifically, it includes engraving a number of circular light-transmitting small holes 2 on the black ink layer 1d of the IR sensing area 1c, and the number of light-transmitting small holes 2 satisfy the following mathematical model: In the formula, a is the hole spacing in the horizontal direction, taking a value of 0.04mm; b is the hole spacing in the vertical direction, taking a value of 0.1mm; d is the hole diameter, taking a value of 0.05mm; T is the transmittance, taking The value is 16.8%, and its allowable error is ±0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com