A Modeling Method for Series Battery System Based on Parameter Corrector

A battery system and parameter calibration technology, which is applied in the direction of instruments, electrical digital data processing, special data processing applications, etc., can solve the problems of inconsistency in the performance parameters of battery cells, and achieve the effect of high prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with specific examples, which are for explanation of the present invention rather than limitation.

[0022] 1. Series battery system and battery cell model

[0023] 1.1 Series battery system

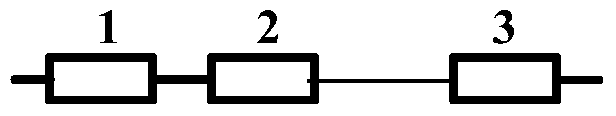

[0024] The series battery system is composed of three battery cells connected in series, and its structure diagram is as follows: figure 1 shown. The rated voltage of each battery cell is 3.7V, the rated capacity is 860mAh, and the discharge cut-off voltage is 3V.

[0025] 1.2 Equivalent circuit model of battery cell

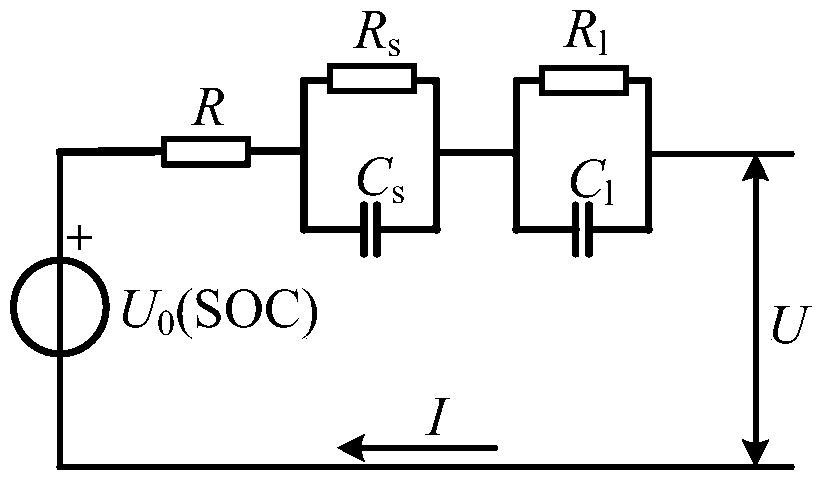

[0026] The equivalent circuit model of a battery cell is a second-order equivalent circuit model. The main circuit of the model consists of two RC parallel circuits, a controlled voltage source U 0 (SOC) and battery internal resistance R, etc., the circuit diagram is as follows figure 2 As shown, the mathematical model expression is: U(t)=U 0 [SOC(t)]-I(t)[R(t)+R s (t) / R s (t)jωC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com