A high-performance sintered NdFeB rare earth permanent magnet material and its preparation method

A rare earth permanent magnet, NdFeB technology, applied in the direction of magnetic materials, inorganic material magnetism, magnetic objects, etc., can solve the problem of failing to meet the design requirements of the main phase, achieve small impact on remanence, improve coercivity, reduce The effect of boundary defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

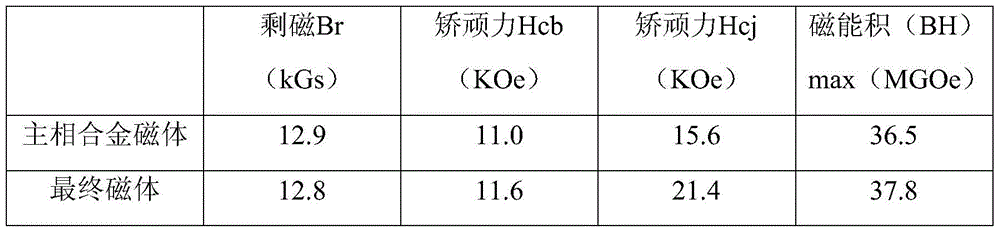

Embodiment 1

[0030] The first main phase magnetic powder alloy composition Nd 24 PR 6 co 1.8 Fe 61.1 Nb 0.6 al 0.30 Cu 0.2 B 1.0(mass percentage content), use the SC process to make flakes, use hydrogen explosion treatment to make the average particle size of the powder below 100 μm, and use hydrogen crushing and jet milling to make magnetic powder with an average particle size of 3.0-5.0 μm. Orientation press molding in 2T orientation magnetic field, isostatic pressing under 180MPa pressure. Sintering at 1050°C*2h, secondary heat treatment, 880°C*2h and 550°C*2h to obtain the first main phase sintered NdFeB magnet.

[0031] Alloy composition Dy of the second boundary zone structure 30 Fe 68.2 Nb 0.6 al 0.3 Cu 0.2 B 1.0 (mass percentage content), using the SC process to make flakes, using hydrogen explosion treatment to make the average particle size of the powder below 100 μm, and using hydrogen crushing and jet milling to make magnetic powder with an average particle size of...

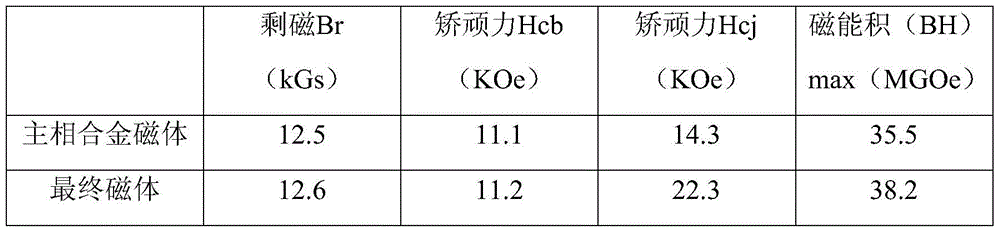

Embodiment 2

[0037] The first main phase magnetic powder alloy composition Nd 24 PR 6 Fe 62.9 Nb 0.6 al 0.30 Cu 0.2 B 1.0 (mass percentage content), use the SC process to make flakes, use hydrogen explosion treatment to make the average particle size of the powder below 100 μm, and use hydrogen crushing and jet milling to make magnetic powder with an average particle size of 3.0-5.0 μm. Orientation press molding in 2T orientation magnetic field, isostatic pressing under 180MPa pressure. Sintering at 1050°C*2h, secondary heat treatment, 880°C*2h and 550°C*2h to obtain the first main phase sintered NdFeB magnet.

[0038] Alloy composition Dy of the second boundary zone structure 30 Fe 68.8 al 0.3 Cu 0.2 B 1.0 (mass percentage content), using the SC process to make flakes, using hydrogen explosion treatment to make the average particle size of the powder below 100 μm, and using hydrogen crushing and jet milling to make magnetic powder with an average particle size of 2.5-4.0 μm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com