Manufacturing method of array substrate and array substrate

A technology of an array substrate and a manufacturing method, which is applied in the display field, can solve problems such as surface defects of polysilicon layers, influence TFT characteristics, etc., and achieve the effect of improving loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

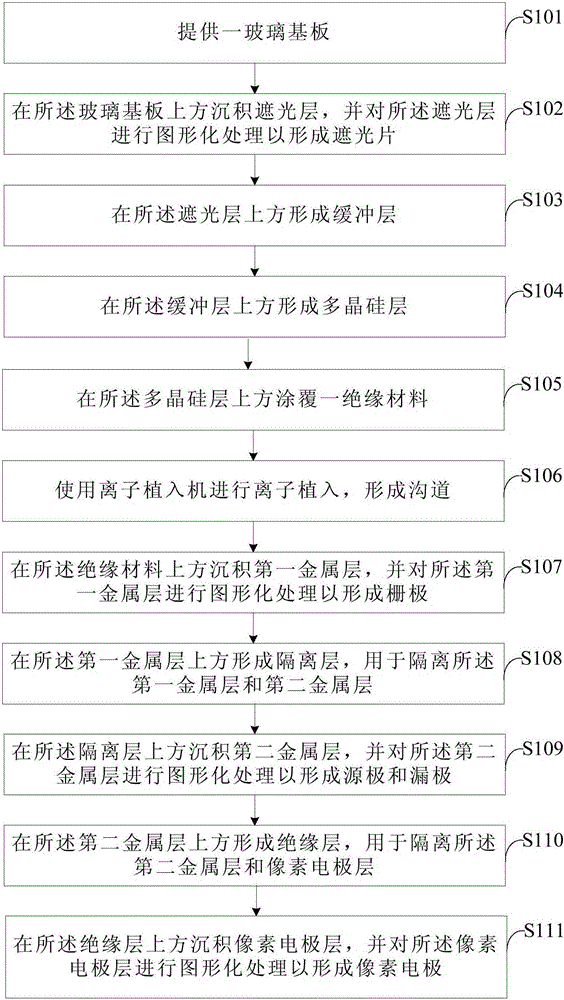

[0068] see figure 2 , is the implementation process of the method for manufacturing an array substrate provided in Embodiment 1 of the present invention, which mainly includes the following steps:

[0069] In step S201, a glass substrate is provided;

[0070] In step S202, a light-shielding layer is deposited on the glass substrate, and the light-shielding layer is patterned to form a light-shielding sheet;

[0071]In step S203, a buffer layer is formed on the light shielding layer;

[0072] In the embodiment of the present invention, a silicon nitride layer and a silicon oxide layer are sequentially formed on the light shielding layer, so as to obtain a buffer layer.

[0073] In step S204, forming a polysilicon layer on the buffer layer;

[0074] In an embodiment of the present invention, an amorphous silicon layer is formed on the buffer layer;

[0075] An excimer laser annealing operation is performed on the amorphous silicon layer to form a polycrystalline silicon lay...

Embodiment 2

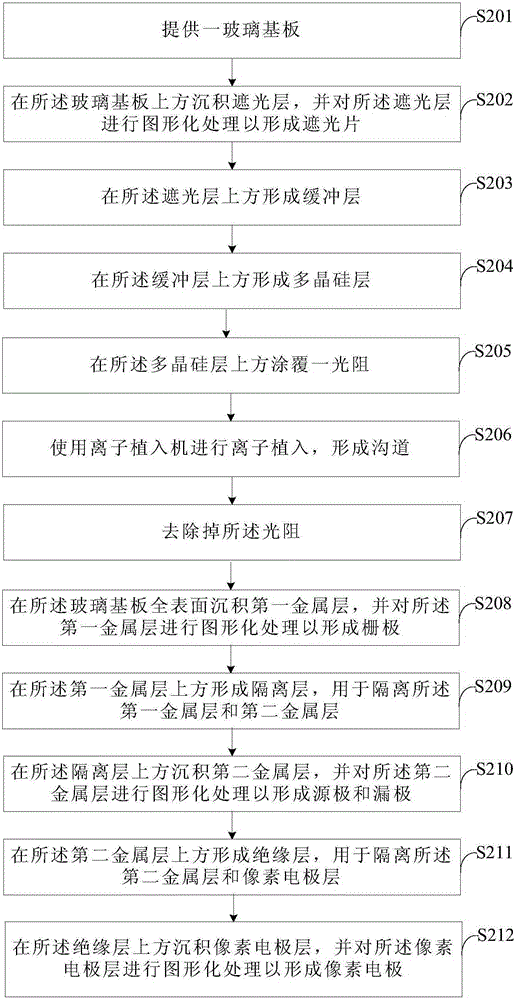

[0088] see image 3 , is the implementation process of the method for manufacturing an array substrate provided in Embodiment 2 of the present invention, which mainly includes the following steps:

[0089] In step S301, a glass substrate is provided;

[0090] In step S302, a light-shielding layer is deposited on the glass substrate, and the light-shielding layer is patterned to form a light-shielding sheet;

[0091] In step S303, a buffer layer is formed on the light shielding layer;

[0092] In the embodiment of the present invention, a silicon nitride layer and a silicon oxide layer are sequentially formed on the light shielding layer, so as to obtain a buffer layer.

[0093] In step S304, forming a polysilicon layer on the buffer layer;

[0094] In an embodiment of the present invention, an amorphous silicon layer is formed on the buffer layer;

[0095] An excimer laser annealing operation is performed on the amorphous silicon layer to form a polycrystalline silicon lay...

Embodiment 3

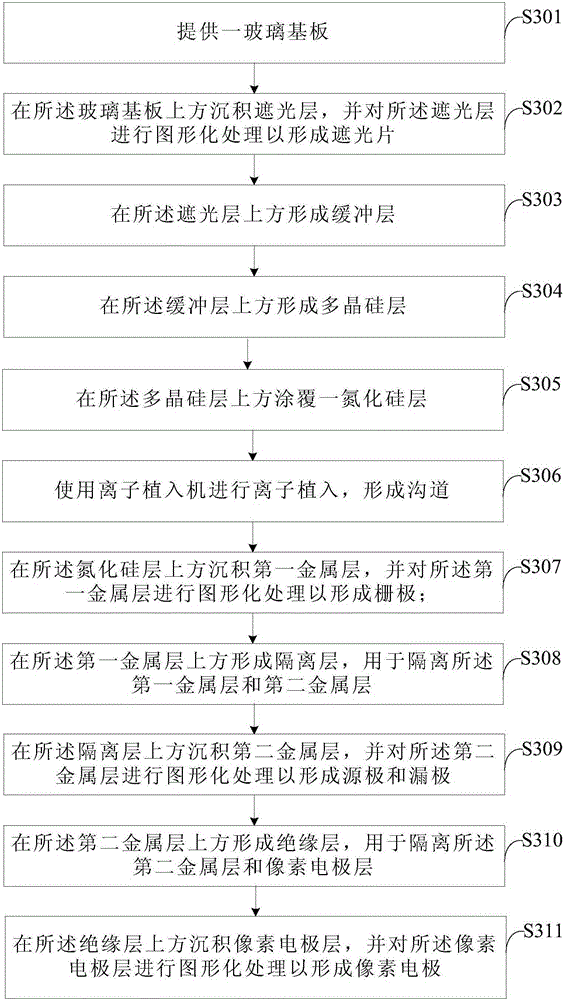

[0107] see Figure 4 , is the implementation process of the method for manufacturing an array substrate provided in Embodiment 3 of the present invention, which mainly includes the following steps:

[0108] In step S401, a glass substrate is provided;

[0109] In step S402, a light-shielding layer is deposited on the glass substrate, and the light-shielding layer is patterned to form a light-shielding sheet;

[0110] In step S403, a buffer layer is formed on the light shielding layer;

[0111] In the embodiment of the present invention, a silicon nitride layer and a silicon oxide layer are sequentially formed on the light shielding layer, so as to obtain a buffer layer.

[0112] In step S404, forming a polysilicon layer on the buffer layer;

[0113] In an embodiment of the present invention, an amorphous silicon layer is formed on the buffer layer;

[0114] An excimer laser annealing operation is performed on the amorphous silicon layer to form a polycrystalline silicon la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com