Heat management system for power batteries and control method

A thermal management system and power battery technology, applied in battery/fuel cell control devices, batteries, secondary batteries, etc., can solve problems such as temperature imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

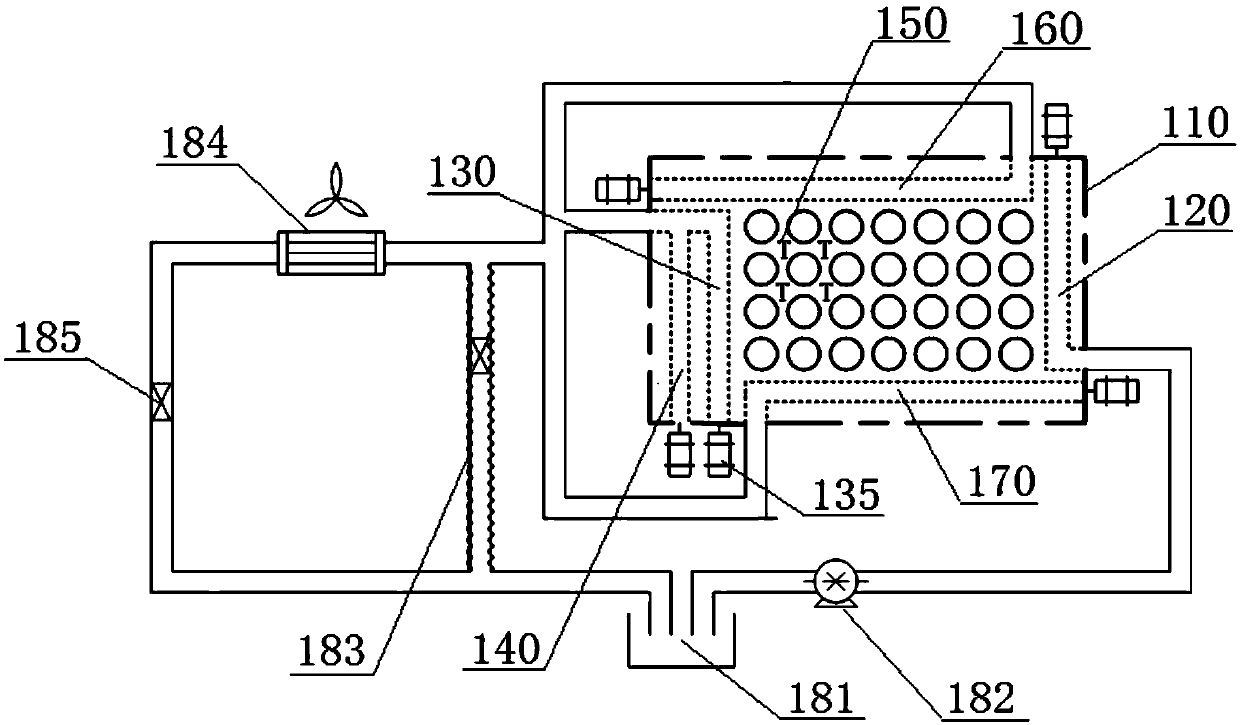

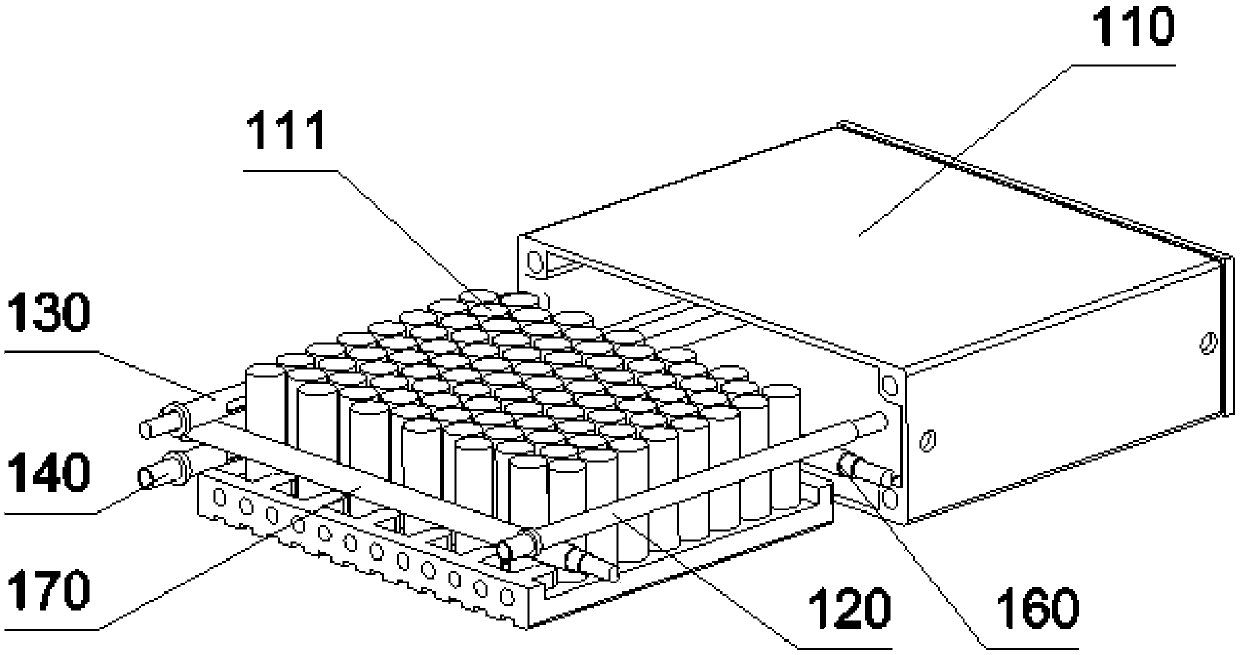

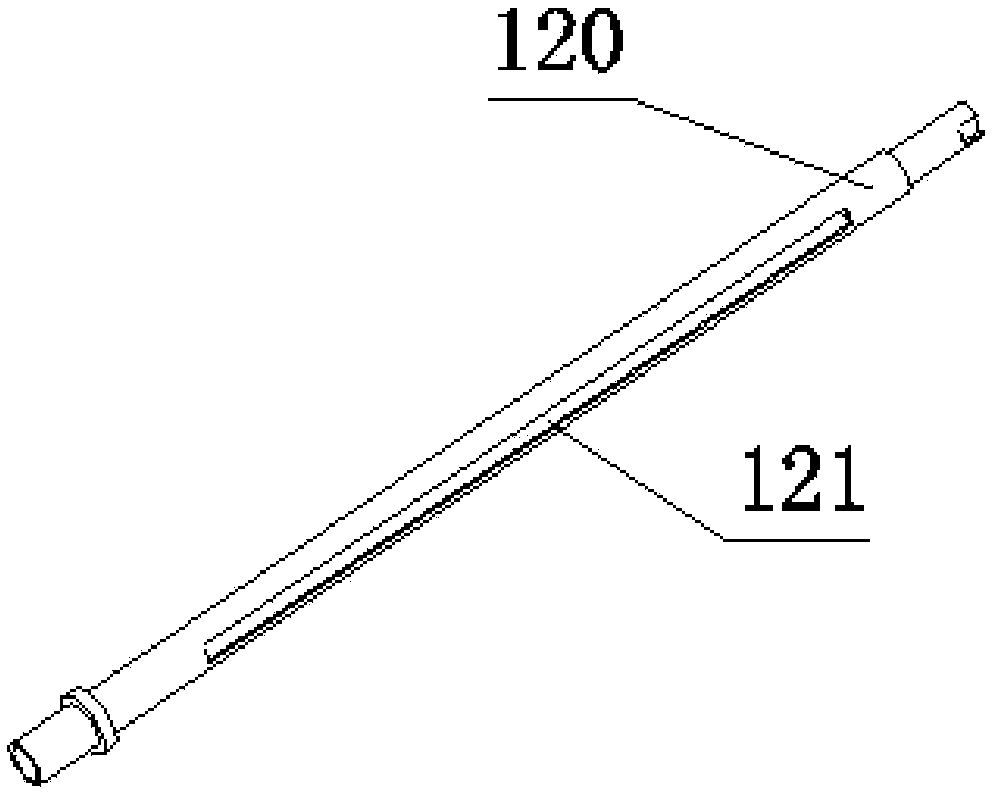

[0058] like figure 1 As shown, the present invention provides a power battery thermal management system, including a battery box 110, a main oil inlet pipe 120, a main oil outlet pipe 130, a first oil outlet pipe 140, a temperature sensor 150 and an external circulation system.

[0059] see also figure 2 , the battery box 110 is in the shape of a cuboid, and the battery box 110 is kept airtight. In the battery box 110, a battery pack composed of several battery cells 111 connected in series and parallel through wires is placed, and each battery cell 111 maintains the same distance, evenly arranged in the battery box 110. The battery cell 111 is cylindrical, the axis of the battery cell 111 is perpendicular to the horizontal plane, and the external terminals of the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com