YIG electrically tunable filter magnetic circuit structure with high temperature stability

An ESC filter and stability technology, applied in circuits, waveguide-type devices, electrical components, etc., can solve the problems of large coil power consumption and large temperature drift of the filter, so as to reduce the magnetic circuit, reduce the temperature drift, The effect of improving temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

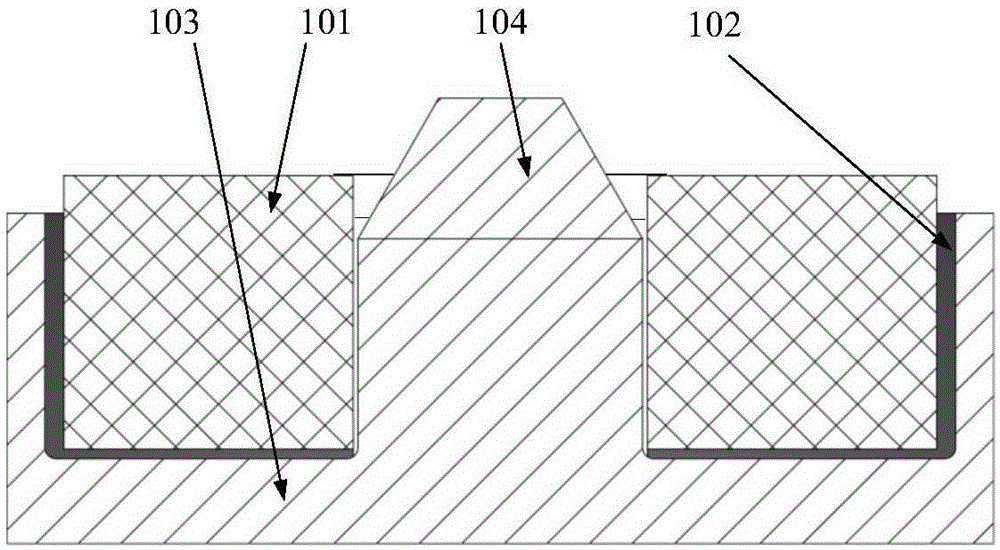

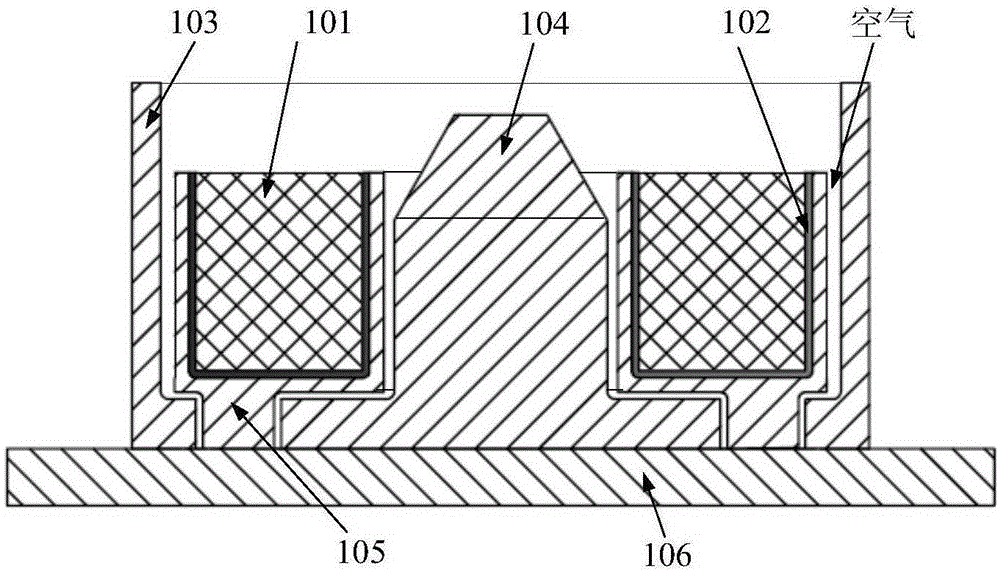

[0030] A high temperature stability YIG electric filter magnetic circuit structure, figure 2 is a schematic diagram of the magnetic circuit structure of the electronically tunable filter, image 3 is a schematic cross-sectional view of the magnetic circuit structure of the present invention, such as figure 2 with image 3 Shown:

[0031] The tuning coil 101 is fixed on the heat conduction bracket 105 through the heat conduction silica gel 102;

[0032] The upper part of the heat conduction bracket 105 is a U-shaped ring structure, which is placed in the annular groove formed by the casing 103 and the pole head 104; the upper part of the heat conduction bracket 105 is not in contact with the casing and the pole head;

[0033] The heat conduction support 105 is fixed on the cooling block 106 through the casing through a plurality of pillars provided at the bottom; the plurality of pillars are not in contact with the casing 103 .

[0034] Preferred:

[0035] The heat condu...

Embodiment 2

[0039] The present invention additionally provides a heat conduction bracket for YIG electric tuning filter, Figure 4 It is a perspective view schematic diagram of the heat conduction bracket of the present invention; Figure 5 is a schematic front view of the heat conduction bracket of the present invention; Image 6 It is a schematic diagram of the back side of the heat conduction bracket of the present invention; Figure 7 It is a schematic cross-sectional view of the heat conducting bracket of the present invention.

[0040] As shown in the figure, the upper part of the heat conduction bracket is a U-shaped ring structure, which is used to hold up the tuning coil; the lower part of the heat conduction support is a plurality of heat conduction pillars, which are used to fix the heat dissipation block; pole head contact.

[0041] When in use, the high-performance heat conduction bracket is fixed on the cooling block, and the cooling block is fixed on the casing, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com