Photovoltaic generation box transformer substation

A photovoltaic power generation box and box-changing technology, which is applied in distribution substations, electrical components, substation/switch layout details, etc., can solve the problems of environmental pollution, maintenance time and high cost, and achieve convenient replacement of fuses, reduce maintenance costs, The effect of reducing the risk of environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

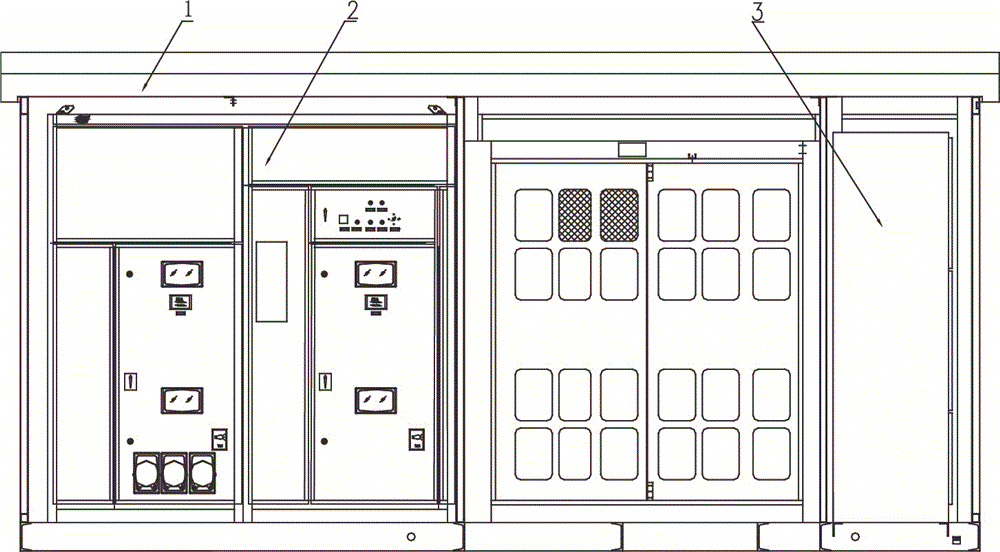

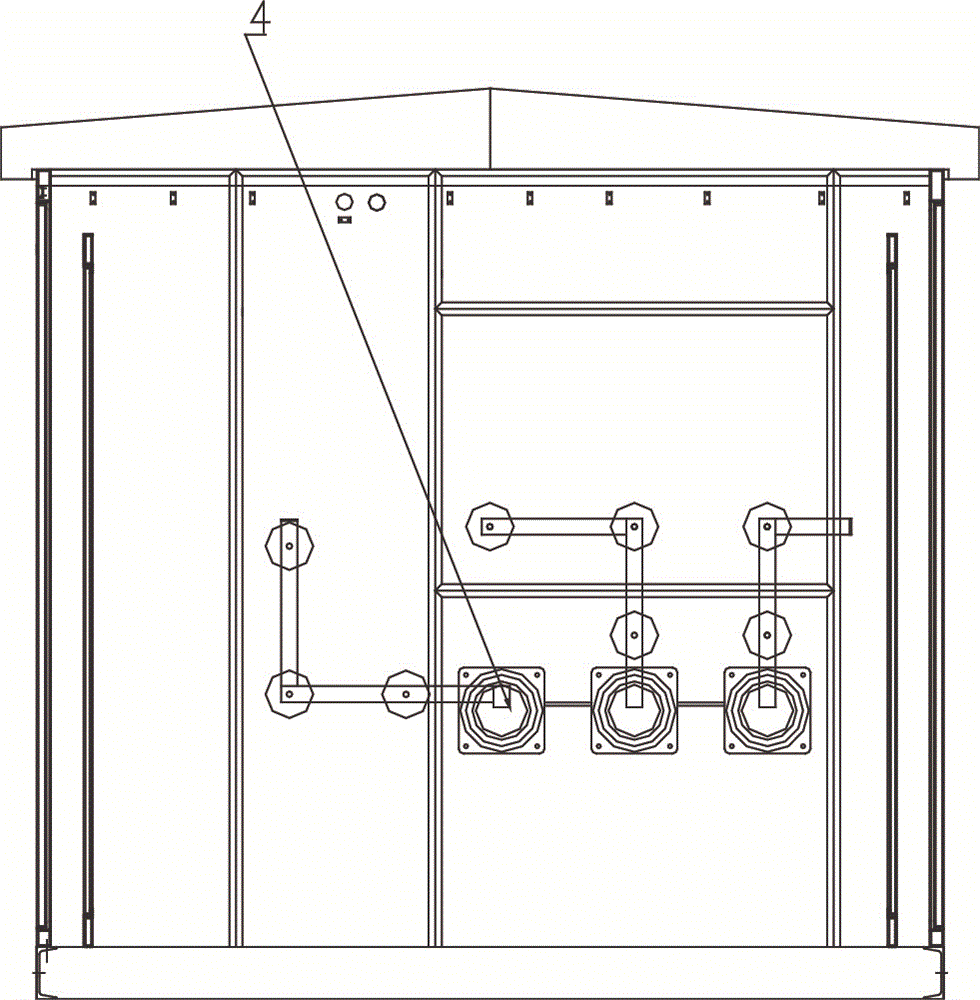

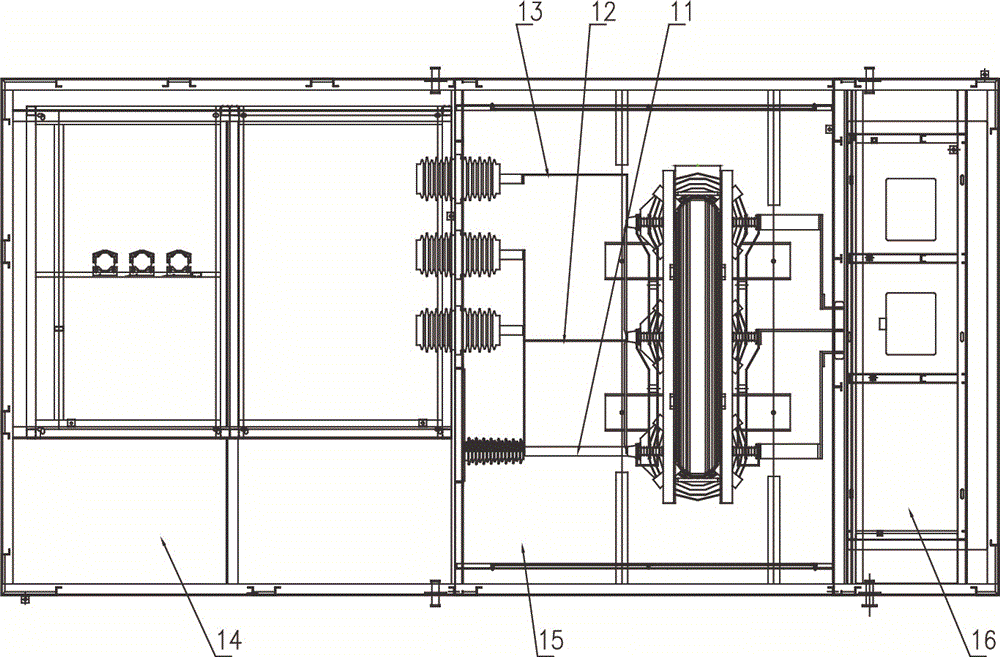

[0017] The photovoltaic power generation box change includes a box change casing 17, and the box change casing 17 is provided with a high-voltage chamber 14, a transformer chamber 15, and a low-voltage chamber 16, and a high-voltage cabinet 2 is placed in the high-voltage chamber 14. A transformer 7 is placed in the transformer chamber 15, a low-voltage cabinet 3 is placed in the low-voltage chamber 16, and the high-voltage side of the transformer 7 is connected with copper bars A11, copper bars B12, and copper bars C13. The copper bars The other side of A11, copper bar B12, and copper bar C13 is connected to the wall bushing 4, the wall bushing 4 is provided with a voltage equalizing ring, and the low voltage side of the transformer 7 is connected to the copper bar D6 and copper row E8, the copper row D6 and the other end of the copper row E8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com