Piezoelectric-triboelectric combined MEMS wideband-energy harvester and preparation method thereof

An energy harvester and piezoelectric energy technology, applied in the field of micro energy, can solve the problems of narrow frequency band and low output power, and achieve the effect of improving output performance, improving output performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The present invention also provides a method for preparing a piezoelectric-triboelectric composite MEMS broadband energy harvester, comprising the following steps:

[0064] S1: Using bonding and thinning techniques to prepare a piezoelectric thick film layer on a silicon wafer, and fabricate a piezoelectric thick film electrode layer (5) on the surface of the piezoelectric thick film (3);

[0065] The silicon wafer refers to an SOI silicon wafer whose upper and lower surfaces are polished on both sides and a layer of silicon dioxide is thermally oxidized on the surface.

[0066] The step of preparing a piezoelectric thick film layer by bonding and thinning technology, specifically includes: combining the single-sided polished piezoelectric body with the silicon wafer through epoxy bonding technology, or combining the polished surface of the piezoelectric body with the silicon wafer After a layer of electrode layer is deposited on the surface, the piezoelectric material ...

Embodiment 1

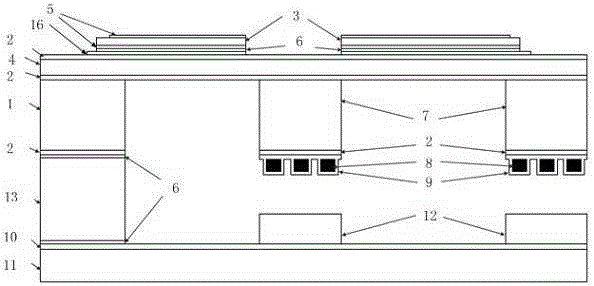

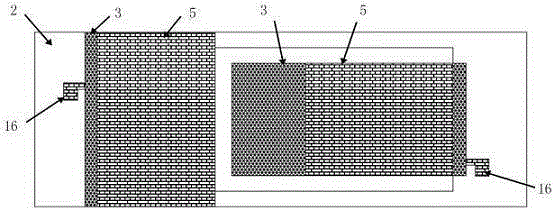

[0082] Such as figure 1 As shown, the piezoelectric-triboelectric composite MEMS energy harvester in this embodiment includes the main structure of the piezoelectric energy harvester, a blocking block and a gasket;

[0083] The main structure of the piezoelectric energy harvester includes: a silicon fixed base, 2 silicon-based piezoelectric cantilever beams and 2 mass blocks;

[0084] The silicon fixed base includes: a silicon wafer (1) and silicon dioxide layers (2) on both sides thereof;

[0085] The silicon-based piezoelectric cantilever beam on the piezoelectric main structure includes: a silicon cantilever beam support layer and a piezoelectric thick film layer attached to the silicon cantilever beam support layer; the silicon cantilever beam support layer includes a second silicon layer (4), a The silicon dioxide layer (2) on the upper and lower surfaces of the second silicon layer (4) and the supporting layer electrode layer (16) on the silicon dioxide layer (2) on the...

Embodiment 2

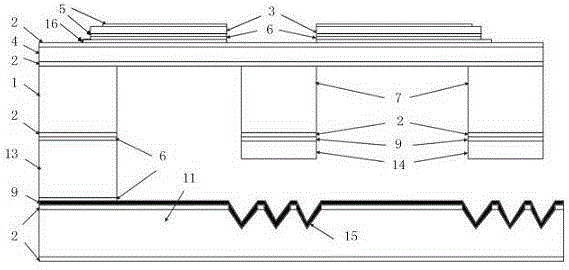

[0114] Such as image 3 As shown, a piezoelectric-triboelectric composite MEMS energy harvester provided in this embodiment includes: a main structure of the piezoelectric energy harvester, a blocking block and a gasket.

[0115] The main structure of the piezoelectric energy harvester includes: a silicon fixed base, 2 silicon-based piezoelectric cantilever beams and 2 mass blocks;

[0116] The silicon fixing base comprises: a silicon wafer (1) and silicon dioxide layers (2) on both sides thereof;

[0117] The silicon-based piezoelectric cantilever beam on the piezoelectric main structure includes: a silicon cantilever beam support layer and a piezoelectric thick film layer attached to the silicon cantilever beam support layer; the silicon cantilever beam support layer includes a second silicon layer (4), a The silicon dioxide layer (2) on the upper and lower surfaces of the second silicon layer (4) and the supporting layer electrode layer (16) on the silicon dioxide layer (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com