Lubricating composition

A kind of lubricating composition, comb polymer technology, applied in the direction of lubricating composition, biofuel, liquid carbon-containing fuel, etc., can solve the problems of engine lubricating protection no longer conforming to viscosity grade, viscosity loss of lubricating composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Further details of the preparation methods of the comb polymers used herein can be found in US2010 / 0190671 and US2008 / 0194443, which are incorporated herein by reference.

[0053] The comb polymer used in the present invention comprises repeating units derived from polyolefin-based macromonomers. These repeat units contain at least one group derived from polyolefins. Examples of suitable polyolefins include C2-C10 alkenes such as ethylene, propylene, n-butene, isobutene, norbornene and / or C4-C10 alkadienes such as butadiene, isoprene, norbornadiene, etc. .

[0054] The repeat units derived from polyolefin-based macromers preferably comprise at least 70 wt%, more preferably at least 80 wt%, most preferably at least 90 wt%, based on the weight of repeat units derived from polyolefin-based macromers % of groups derived from alkenes and / or alkadienes.

[0055] The polymer groups may also be present in hydrogenated form. The repeat units derived from polyolefin-based macro...

Embodiment

[0107] lubricating oil composition

[0108] Formulated with various engine oils for use in engine crankcases.

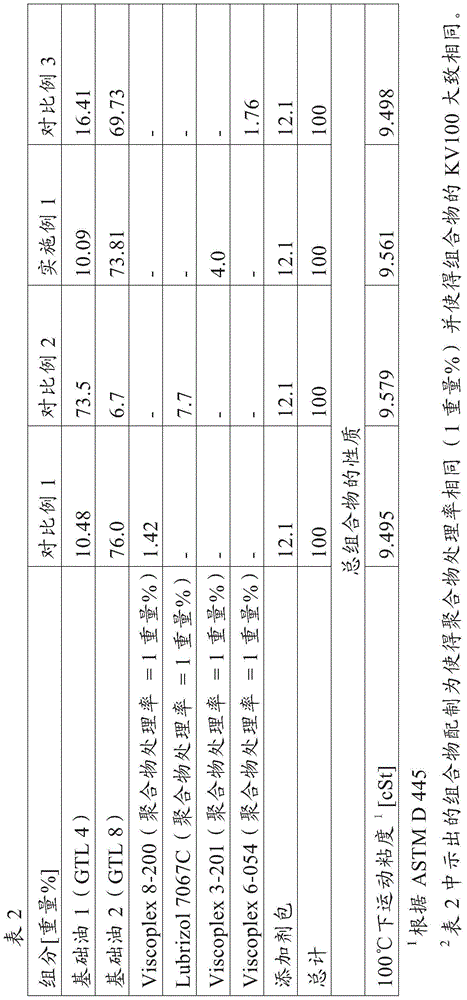

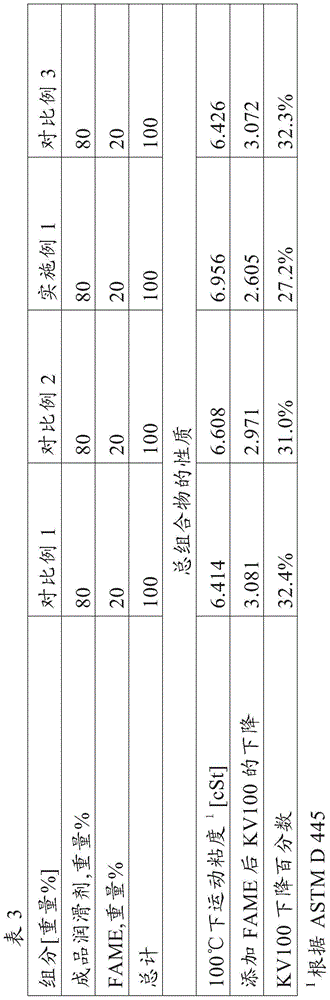

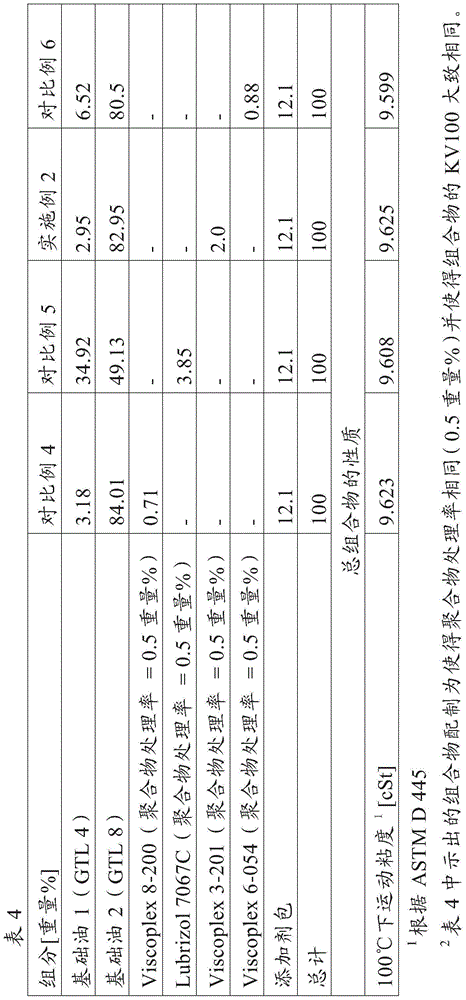

[0109] Table 1 shows the properties of the base oils used. Table 2 shows the composition and properties of the fully formulated engine oil formulations tested; the amounts of components are given in % by weight based on the total weight of the fully formulated formulation.

[0110] "Base oil 1" has a kinematic viscosity (ASTMD445) of about 4 cSt (mm) at 100°C 2 the s -1 ) Fischer-Tropsch derived base oil ("GTL4"). This GTL4 base oil may be suitably prepared by the method described in, for example, WO02 / 070631 (the teaching of which is incorporated herein by reference).

[0111] "Base oil 2" has a kinematic viscosity (ASTMD445) of about 8 cSt (mm) at 100°C 2 the s -1 ) Fischer-Tropsch derived base oil ("GTL8"). This GTL8 base oil may be suitably prepared by, for example, the method described in WO02 / 070631 (the teaching of which is incorporated herein by refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com