Patents

Literature

81 results about "Alkadienes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acyclic branched or unbranched hydrocarbons having two carbon-carbon double bonds.

Preparation method of catalyst for selective hydrogenation of alkyne and alkadiene

InactiveCN103372432AGenerate good effectReduce churnHydrocarbon purification/separationHydrocarbonsAlkaline earth metalCerium

The invention relates to a preparation method of a catalyst for the selective hydrogenation of alkyne and alkadiene. A carrier of the catalyst is a compound of 30-99% of aluminum oxide, 1-50% of titanium oxide, 1-30% of magnetism oxide and 1-40% of zinc oxide based on the weight of the carrier of the catalyst as 100%; meanwhile, an alcohol reagent and an alkali metal or an alkaline-earth metal are used as modifying reagents; the preparation method is an acidity sol mixed kneading molding method; the active components of the catalyst comprise three or more of palladium, gold, silver, bismuth, cerium, lanthanum, tin and antimony, and a loaded solution of the active components is subjected to polymerization; the carrier of the catalyst prepared by the method has relatively low acid content; and the prepared catalyst shows up relatively appropriate reaction activity in the selective hydrogenation reaction of the alkyne and the alkadiene and has relatively good hydrogenation selectivity, relatively strong green oil generation resistance and relatively low palladium wastage rate.

Owner:PETROCHINA CO LTD

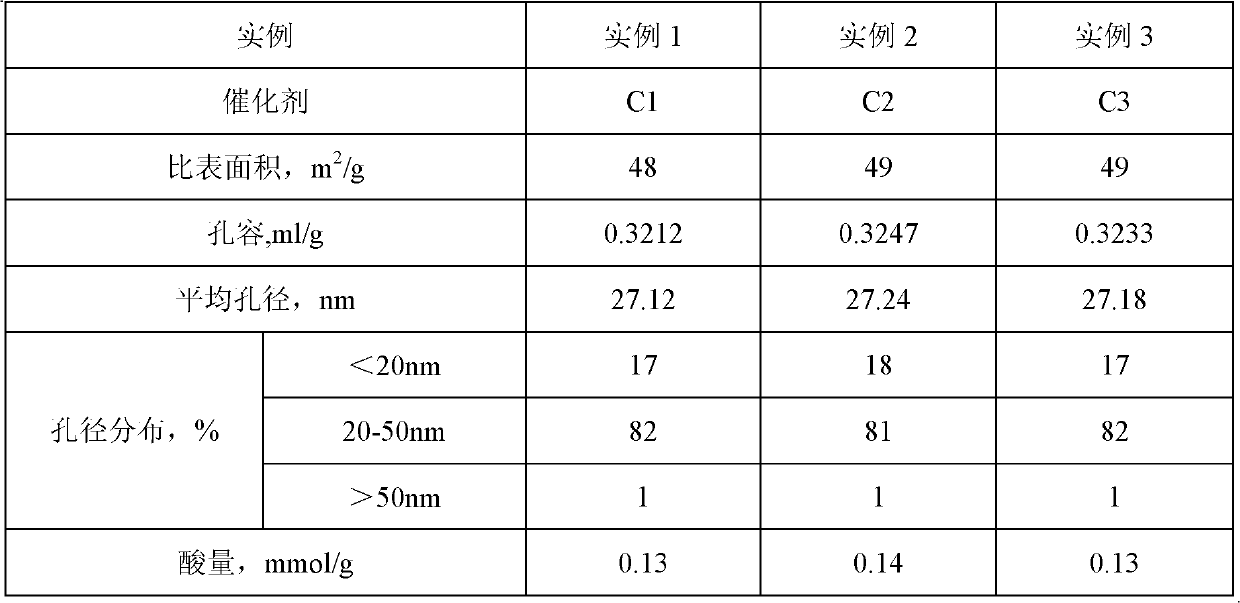

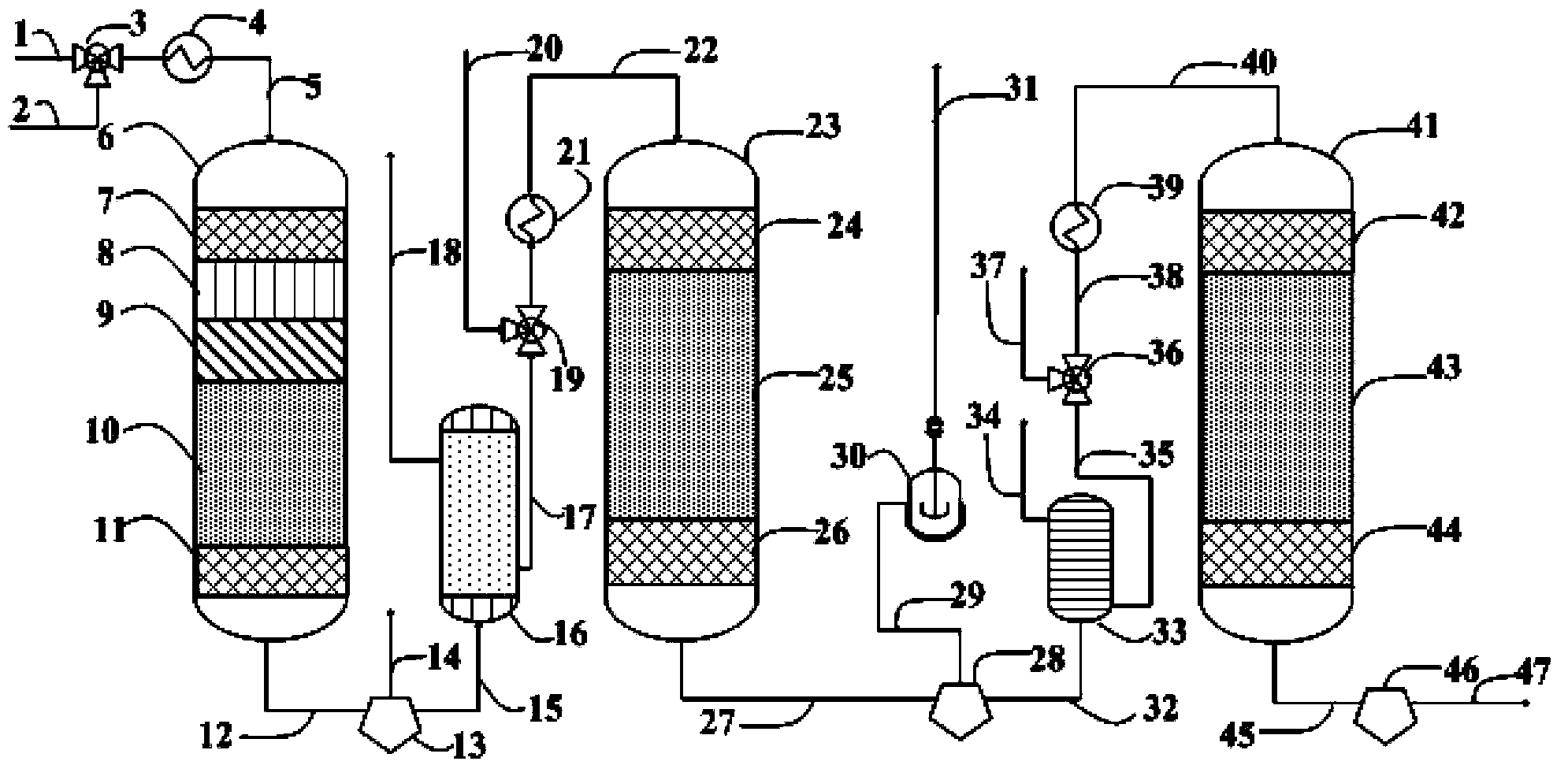

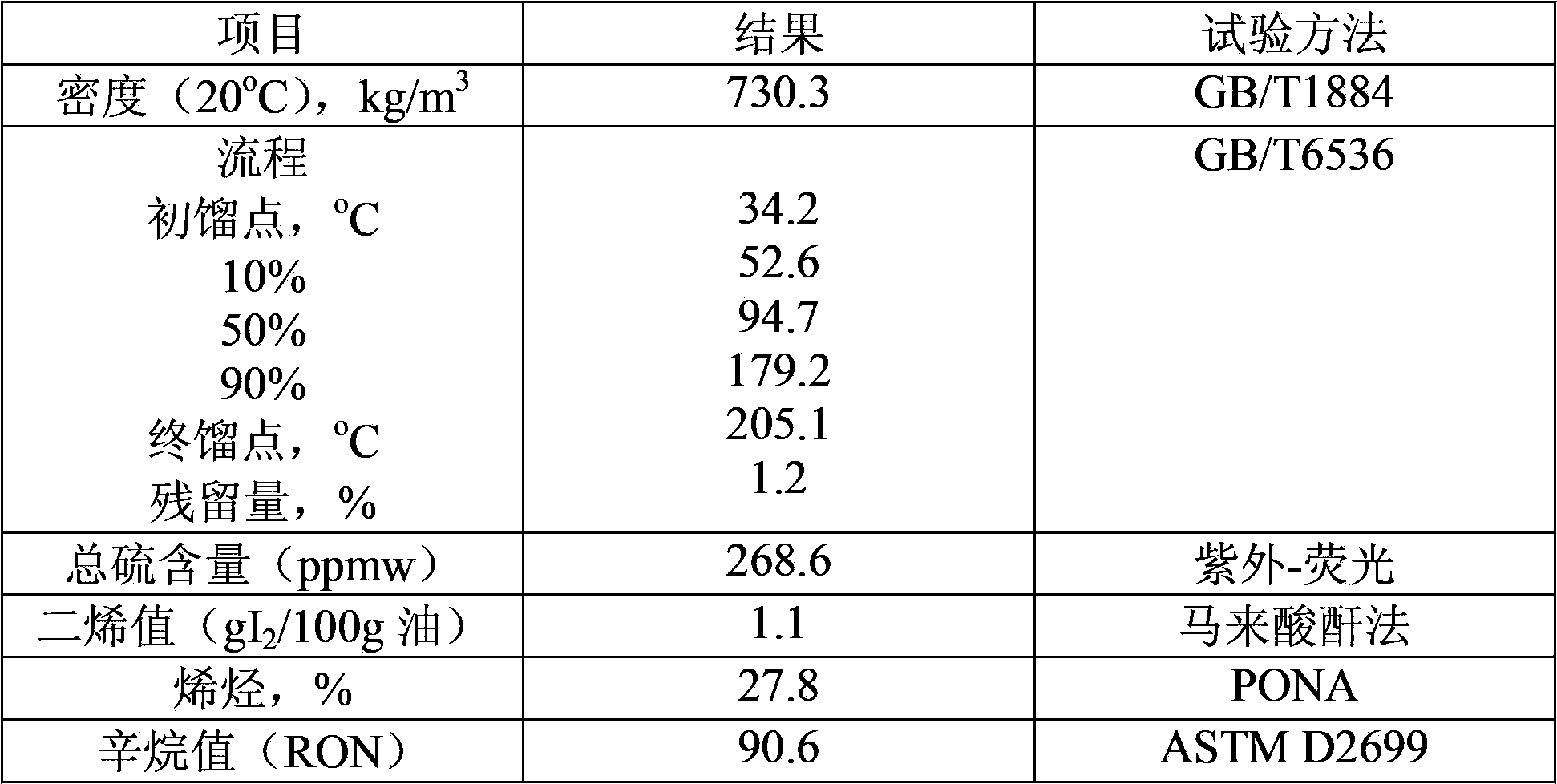

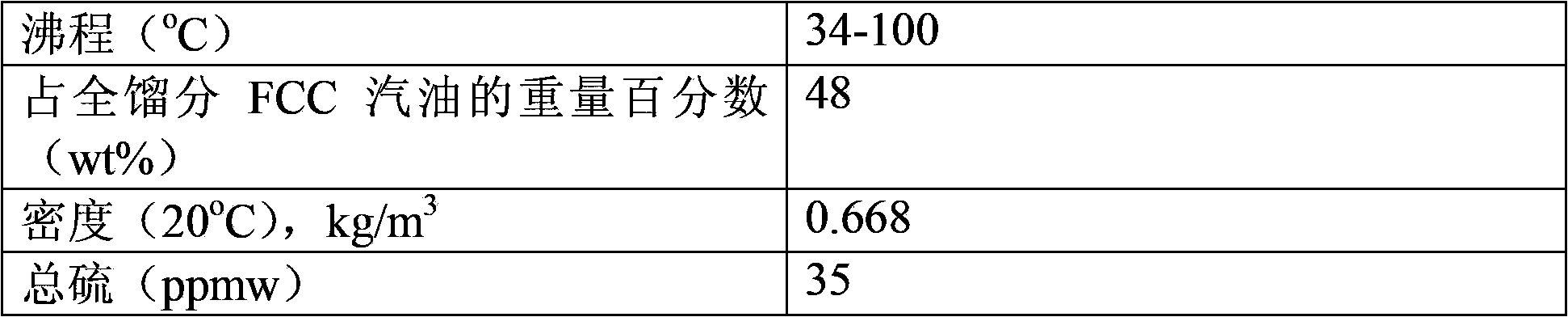

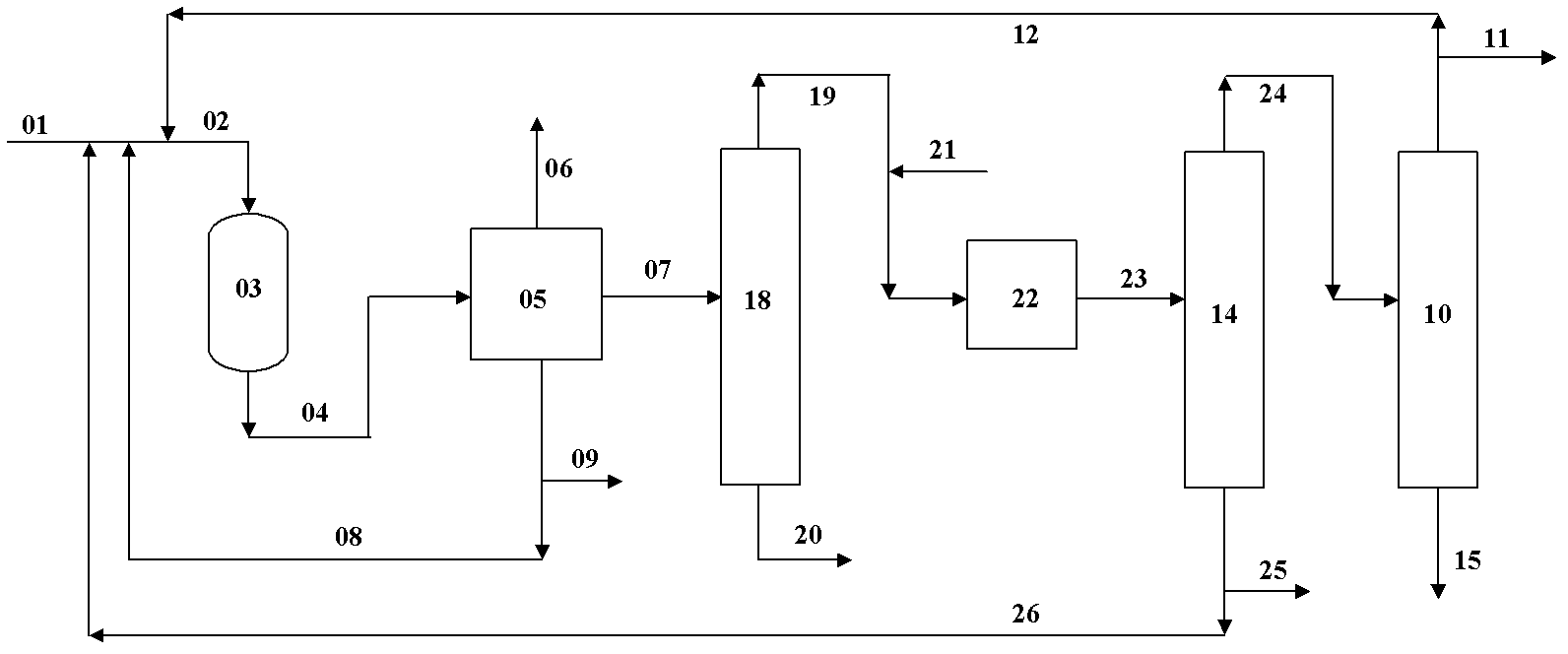

Super deep desulfurization combined method for FCC (fluid catalytic cracking) gasoline

ActiveCN103666559AHigh adsorption selectivityImprove adsorption capacityTreatment with hydrotreatment processesHydrodesulfurizationSorbent

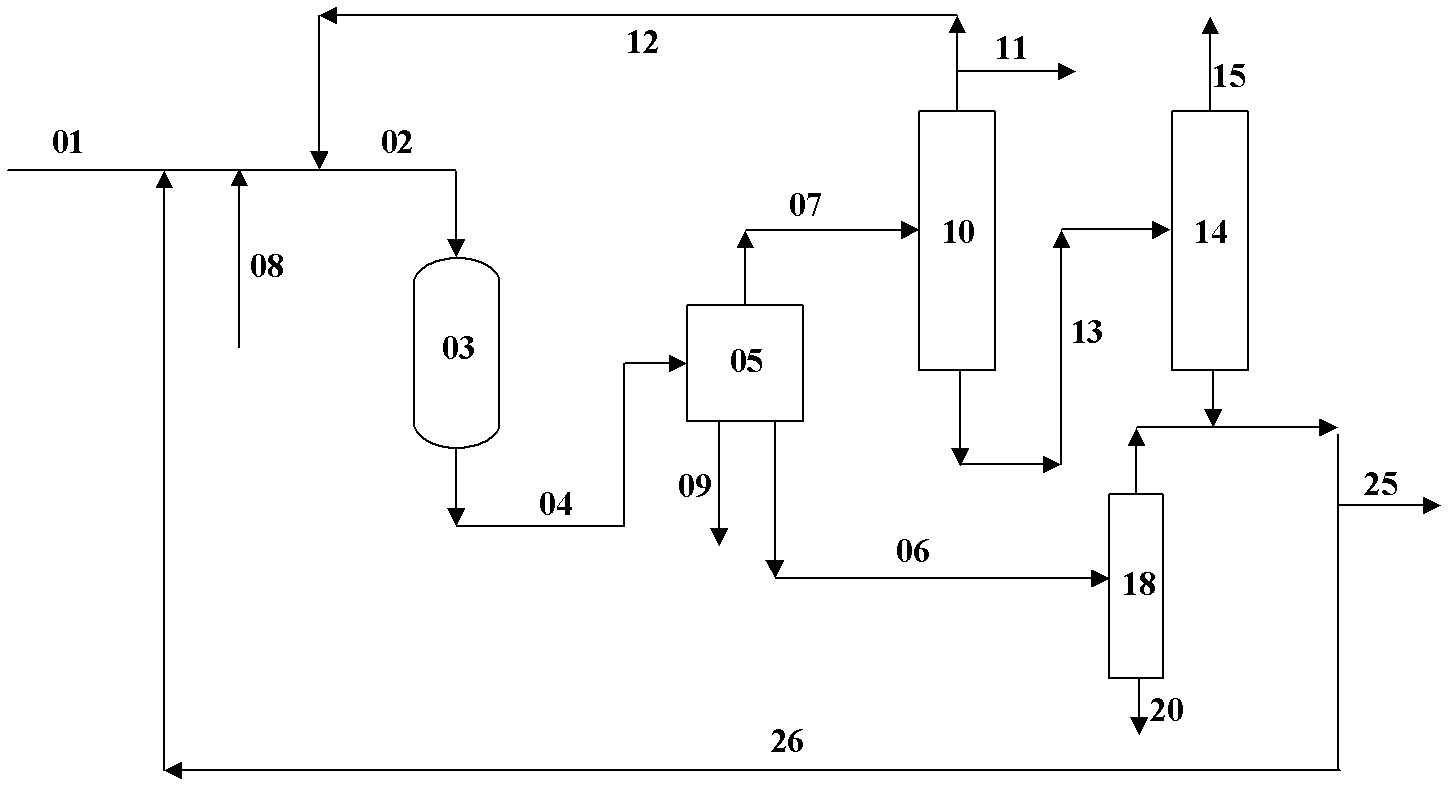

The invention relates to a super deep desulfurization combined method for FCC (fluid catalytic cracking) gasoline. The method comprises the steps of (1) with full fraction FCC gasoline and hydrogen as raw materials, enabling the raw materials to contact with protective agents 1 and 2 and a catalyst selectively removing alkadiene in a reactor removing alkadiene under proper conditions so as to remove most alkadiene in full fraction FCC gasoline raw material; (2) after the full fraction FCC gasoline with alkadiene removed in step (1) passes through a gas-liquid separator, dividing the liquid entering a fractionating tower into a light gasoline fraction and a heavy gasoline fraction; (3) enabling the heavy gasoline fraction obtained in step (2) to contact with the catalyst in a selective hydrogen desulfurization reactor under proper operation condition; (4) mixing the light gasoline fraction obtained in step (2) with the heavy gasoline fraction subjected to selective hydrogen desulfurization in step (3), then mixing with new hydrogen, and enabling the mixture to contact with an adsorbent in an adsorbing super deep desulfurization reactor under proper condition so as to remove most sulphur in the gasoline to obtain the ultra low sulphur gasoline product with content of sulphur less than 10ppmw.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Selective hydrogenation method of alkyne and alkadiene in C4 hydrocarbon material flow

ActiveCN102249835AGuaranteed reaction selectivityGuaranteed reactivityHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPalladium catalystAlkyne

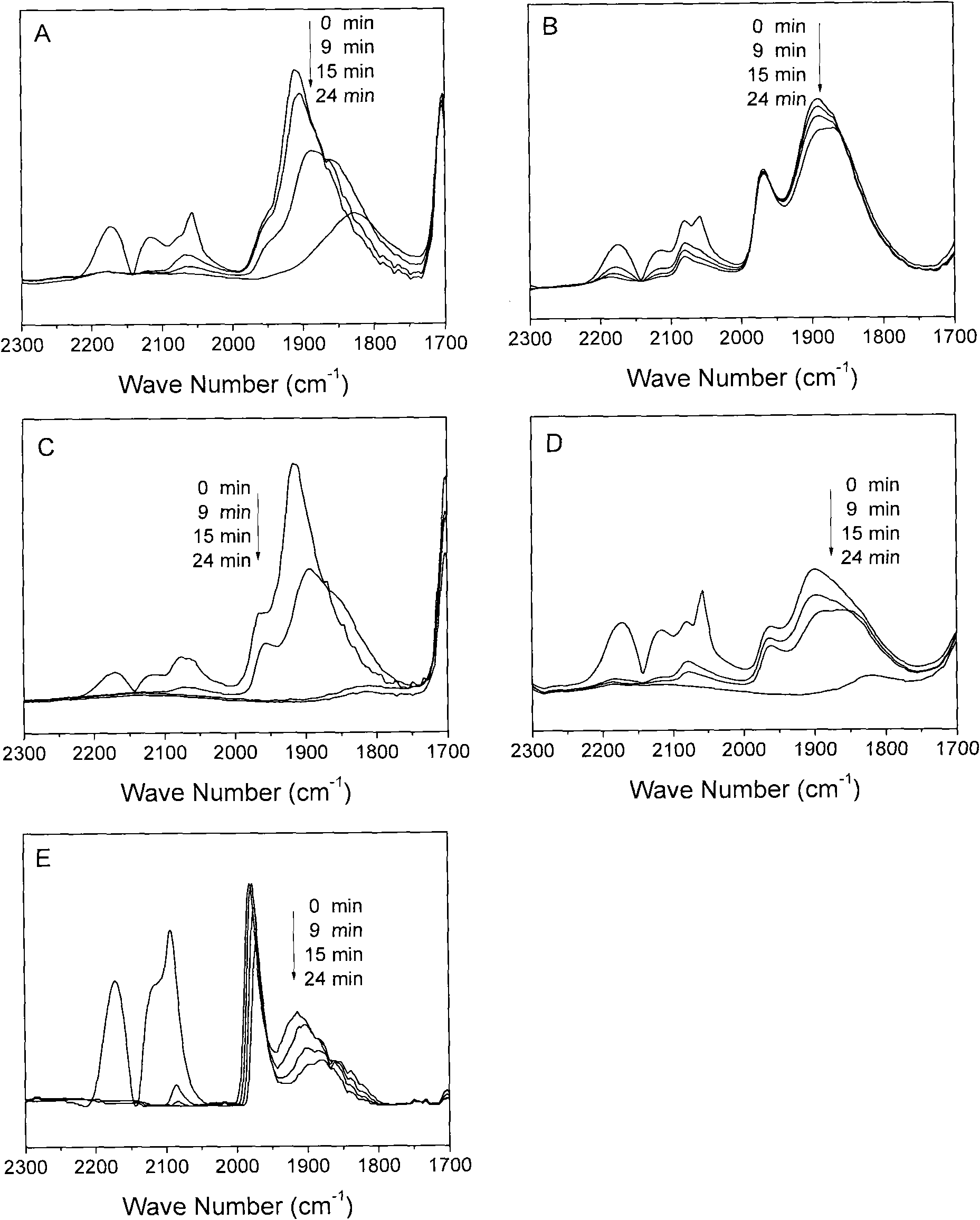

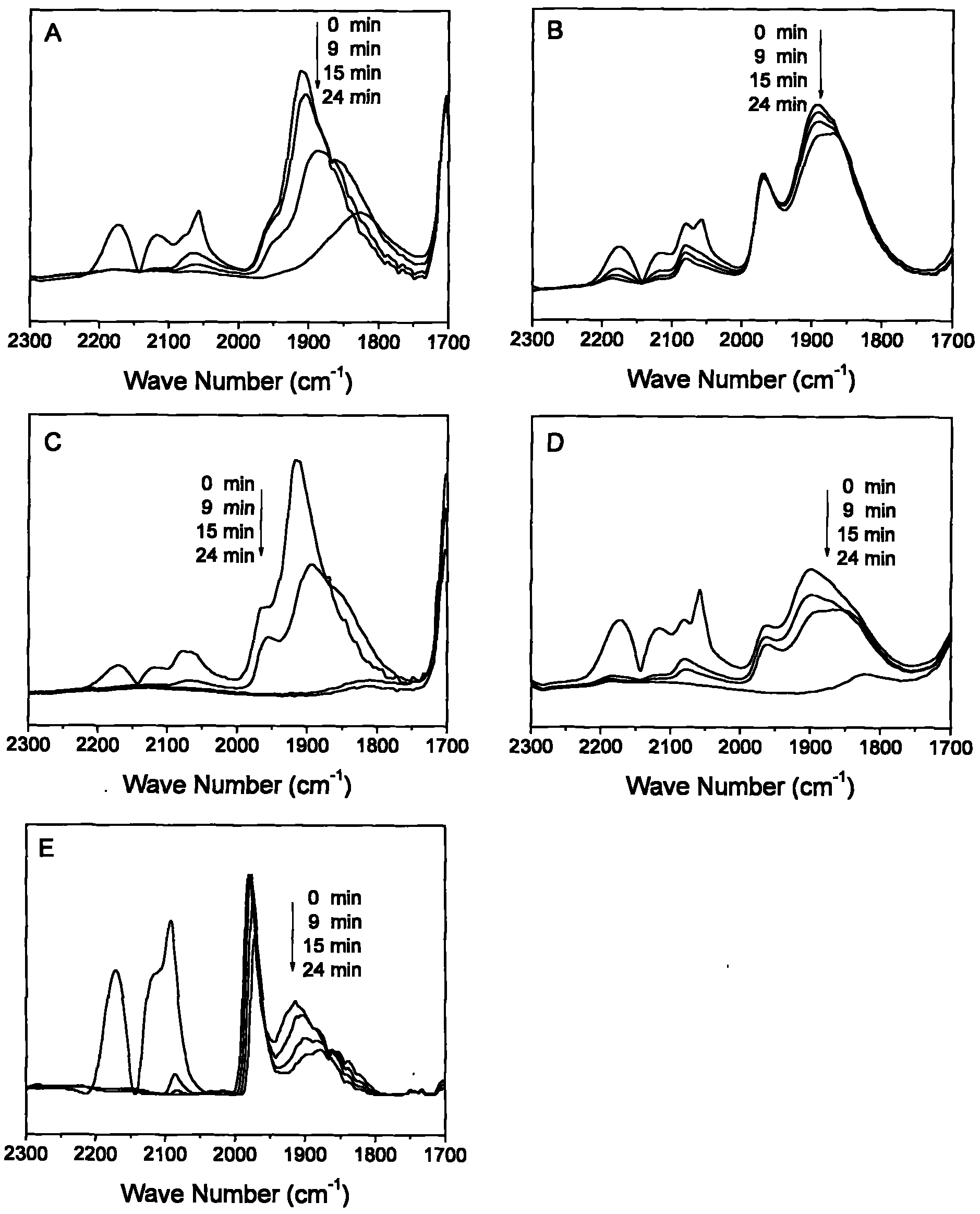

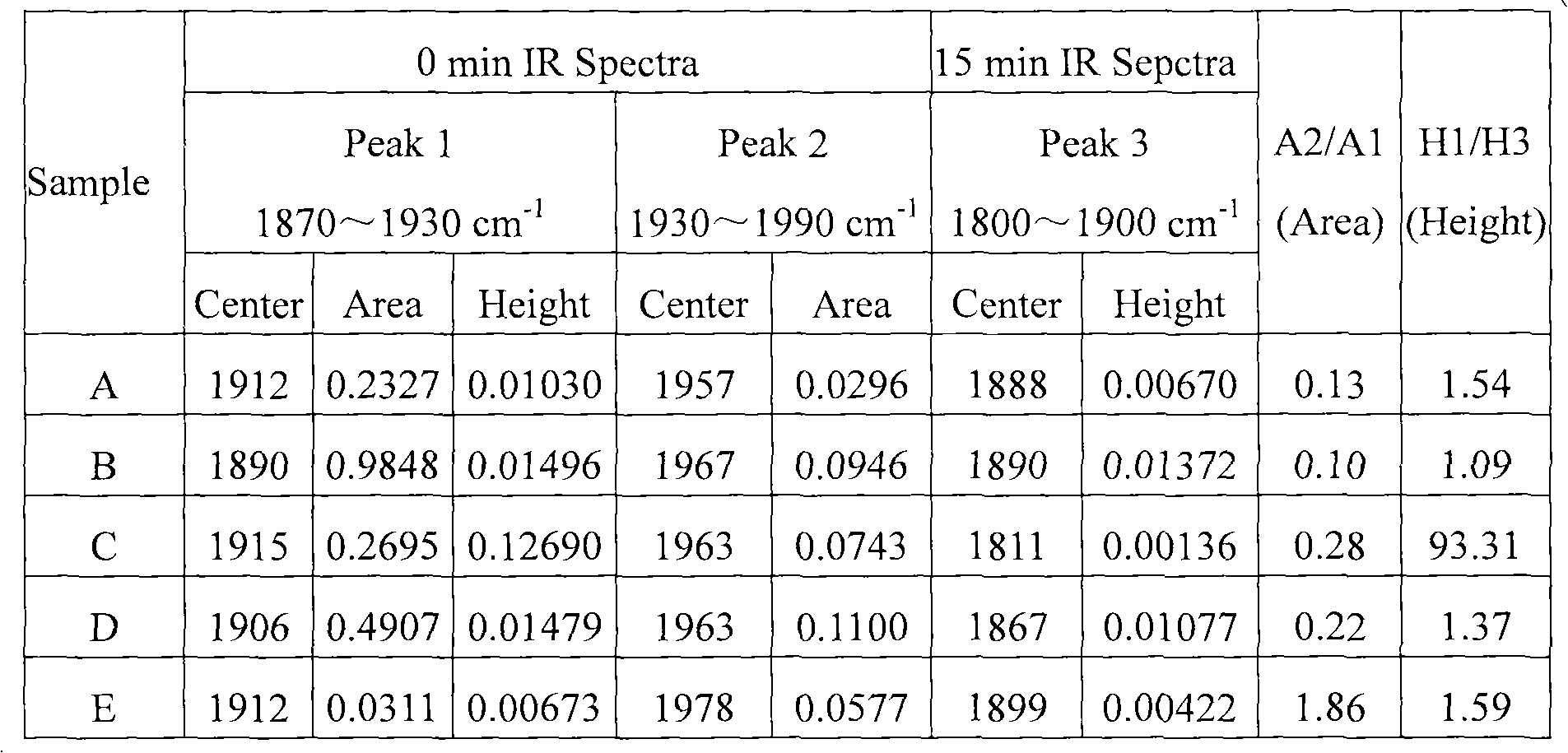

The invention provides a selective hydrogenation method of alkyne and alkadiene in a C4 hydrocarbon material flow. The method provided by the invention comprises the following steps of: adding the C4 hydrocarbon material flow containing alkyne and / or alkadiene and hydrogen gas into a hydrogenation reactor which is filled with a load type palladium catalyst; carrying out the selective hydrogenation on the alkyne and / or alkadiene in the C4 hydrocarbon material flow to form olefin when an inlet temperature is in a range of 10-80 DEG C, a mol ratio of the hydrogen gas to the sum of the alkyne and the alkadiene is 1-10 and a reaction pressure is in a range of 0.1-4 Mpa, and removing the olefin, wherein the load type palladium catalyst comprises a carrier, palladium and selective modified components; testing the load type palladium catalyst by utilizing a carbon monoxide adsorption in-situ infrared spectroscopy at the temperature of 40 DEG C to obtain an area ratio of a bridge type absorption peak at the 1930-1990cm<-1> to a bridge type absorption peak at the 1870-1930cm<-1> in an obtained infrared spectrogram is less than 0.2, more preferably less than 0.15. The method provided by the invention has a high selectivity to the selective hydrogenation of the alkyne and the alkadiene in the C4 hydrocarbon material flow and can be operated for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing propylene from methanol

ActiveCN102875307AExtended regeneration cycleFaster inactivationHydrocarbon purification/separationHydrocarbon from oxygen organic compoundsUnsaturated hydrocarbonFixed bed

The invention relates to a method for preparing propylene from methanol and mainly solves the problem that a present fixed bed technology has disadvantages of short catalyst regeneration period and low propylene yield and a present moving bed technology has disadvantages of large difficulty in continuous coke-burning control of a catalyst and complex flow. According to the method, C5 and the following hydrocarbons obtained from separation of methanol conversion reaction products are subjected to selective hydrogenation treatment, highly unsaturated hydrocarbons such as alkadiene, alkyne and the like are selectively converted into corresponding olefins, and the olefins are recycled. By the adoption of the technical scheme, the above problem is solved well. The method provided by the invention can be applied in industrial production of propylene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

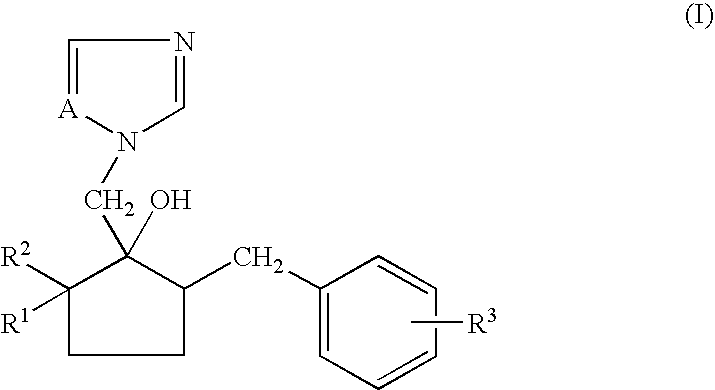

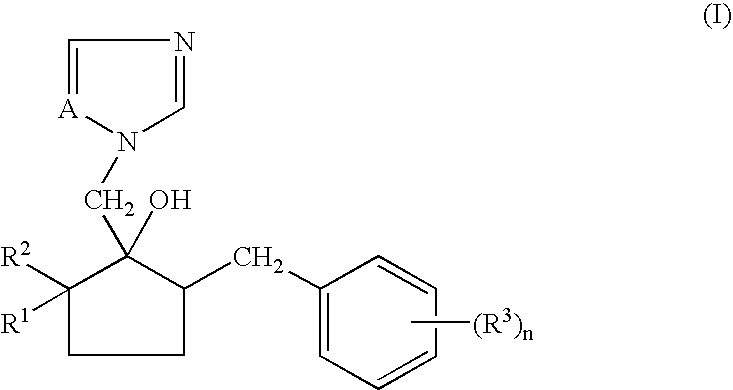

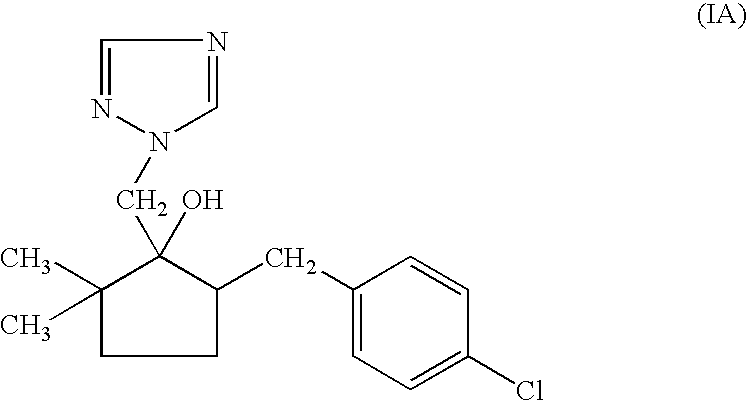

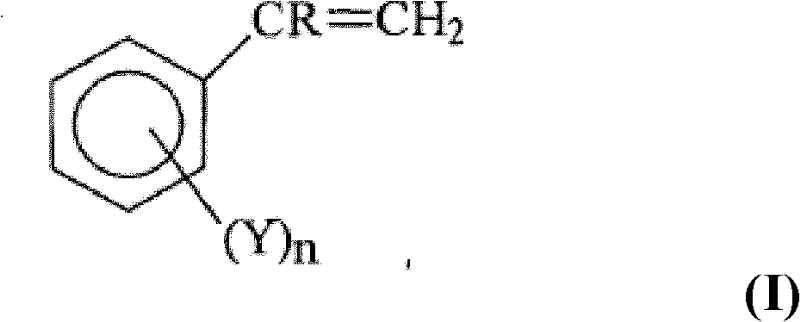

Non-aqueous emulsifiable concentrate formulation

The invention relates to a non-aqueous, emulsifiable concentrate (EC) formulation for crop protection active compounds which comprises(a1) 50 to 300 g / L of at least one azole derivative having a free hydroxy group or a salt or an adduct thereof, preferably a compound of formula I, wherein, R1 and R2 each independently represent hydrogen atom or an optionally substituted alkyl, alkenyl, alkynyl or alkadienyl group;R3 represents a halogen atom or an optionally substituted alkyl, alkenyl, alkynyl, alkadienyl, alkoxy or aryl group;A represents a nitrogen atom or a CH group; andn represents an integer from 0 to 2;(a2) optionally, 50 to 500 g / L of at least one additional fungicidally active compound;(b) up to 700 g / L of one or more alkoxylates of an aliphatic alcohol,(c) up to 100 g / L of one or more non-ionic dispersants,(d) 10 to 100 g / L of one or more anionic dispersants,(e) 50 to 600 g / L of one or more polar aprotic organic solvents, and(f) 150 to 500 g / L of one or more non-polar organic solvents, any(g) up to 5 g / L of one or more defoamers,and to the use of such a emulsifiable concentrate as a fungicide.

Owner:BASF AG

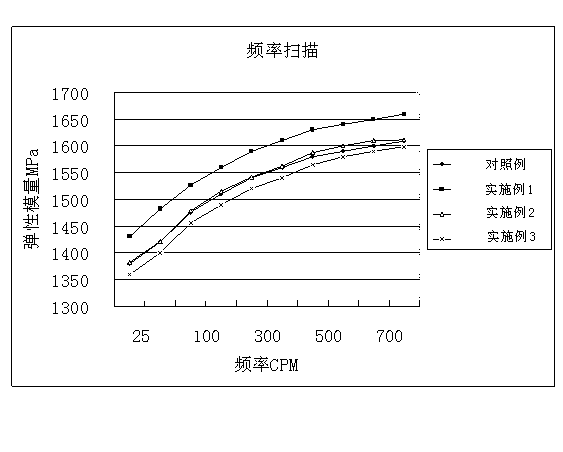

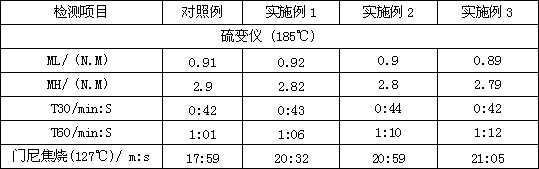

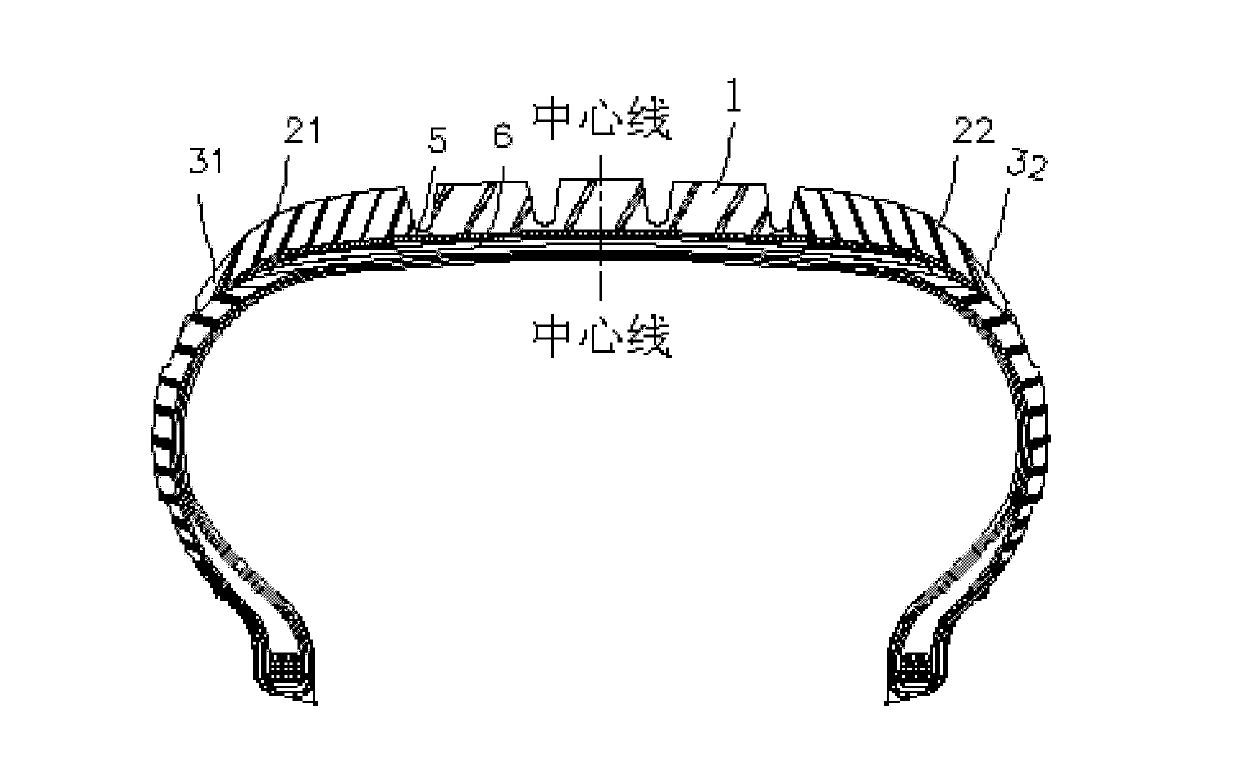

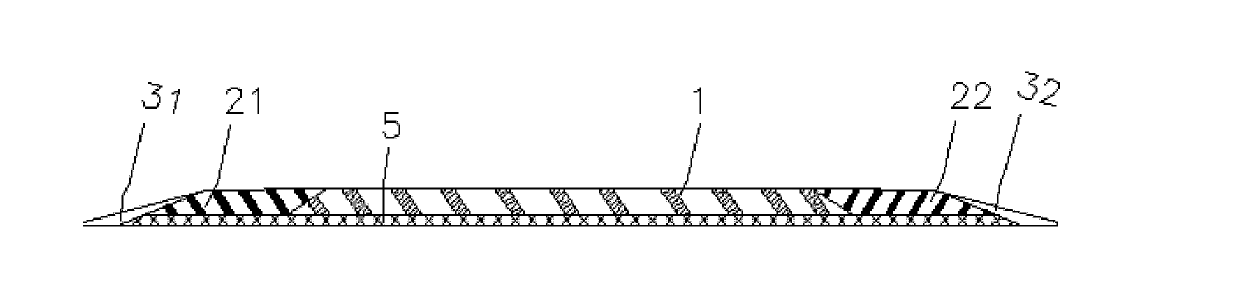

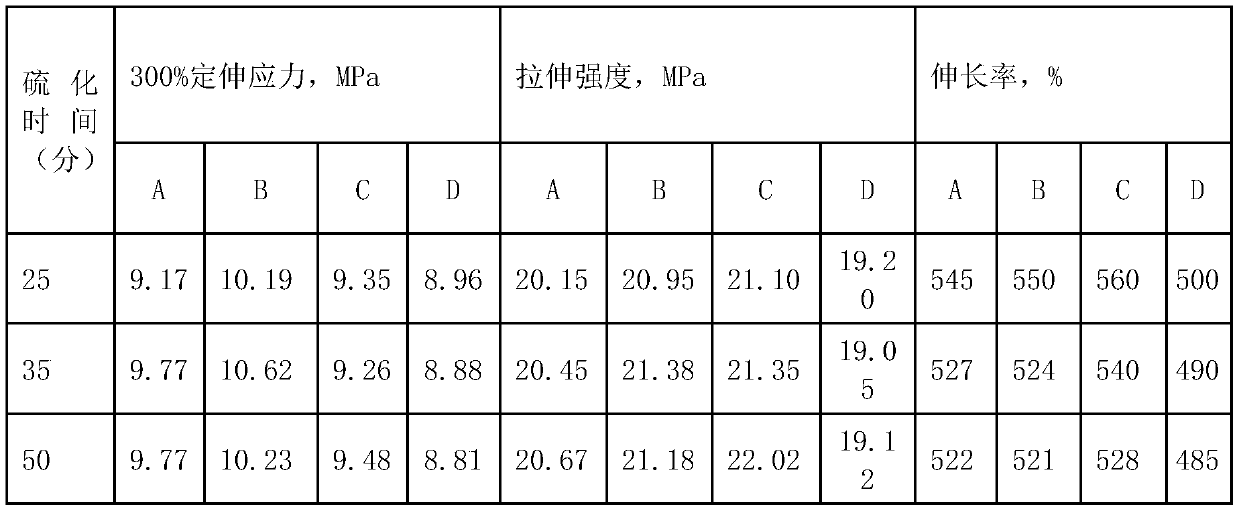

All-steel radial tire belt compound rubber composition and production method thereof

InactiveCN102702586AReduce manufacturing costProtection is goodSpecial tyresRolling resistance optimizationElastomerPolymer science

The invention relates to the technical field of rubber, in particular to an all-steel radial tire belt compound rubber composition, which is characterized by comprising the following materials in parts by weight on the basis of 100 parts by weight of alkadiene elastomer: 30-60 parts of carbon black, 5-15 parts of white carbon black, 3-10 parts of methylene donor, 1-3 parts of environment-friendly resin, 4-10 parts of sulfur, 1-2 parts of cobalt salt and 1-2 parts of accelerant, wherein the environment-friendly resin is obtained from R modified m-phenol diamine, and R mainly represents styrene; and the alkadiene elastomer is selected as one or a mixture of smoke sheet rubber, standard rubber and synthetic polyisoprene rubber. The all-steel radial tire belt compound rubber composition is of great help to reduction of the production cost of the compound; and on the premise of meeting the basic performance such as strength, elongation and resilience of the belt compound, the performances such as an adhesive force between the compound and a steel tire cord and the adhesive force between boundaries of rubber and a steel wire at the later stage of use can be guaranteed.

Owner:TRIANGLE TIRE

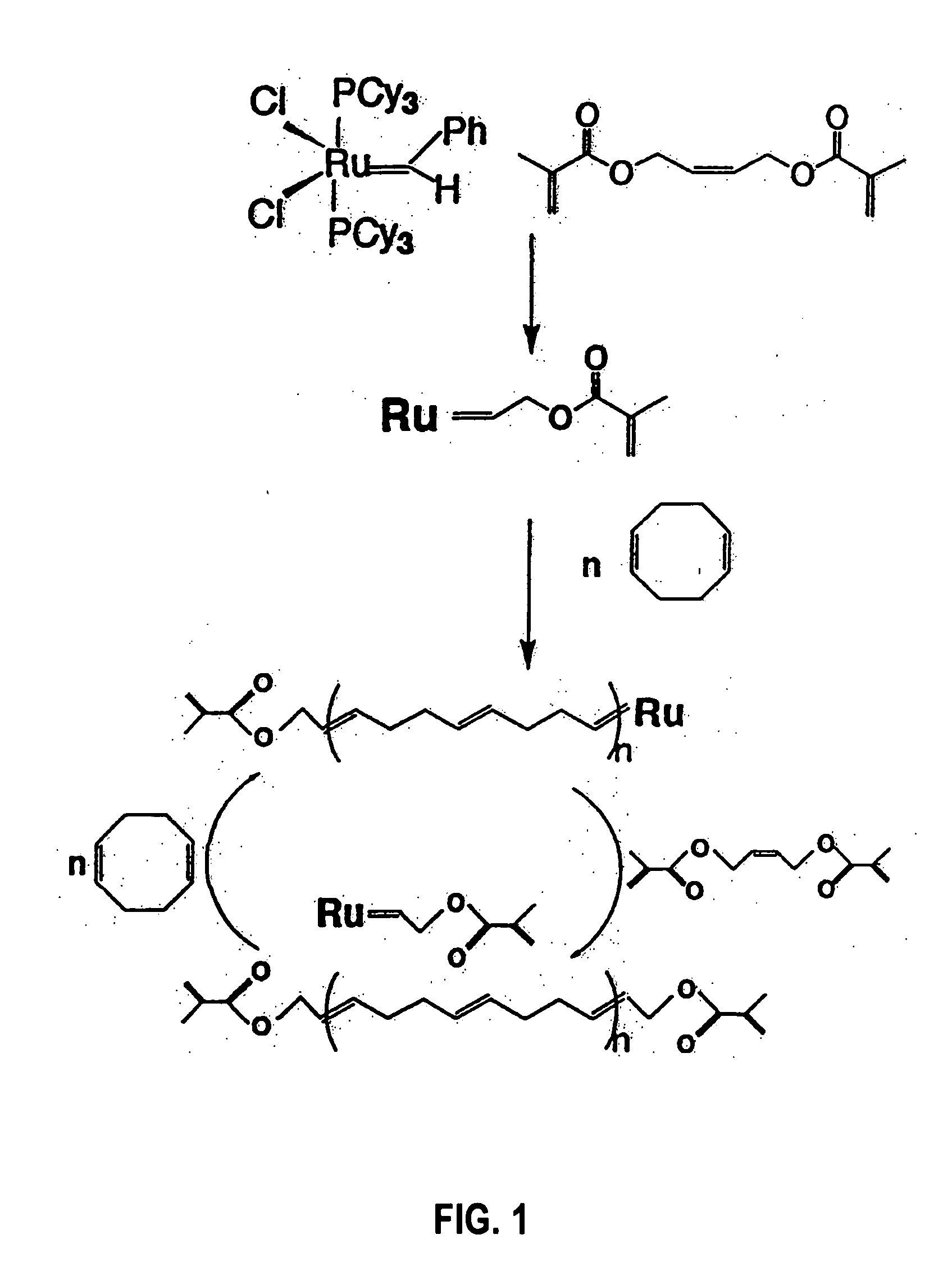

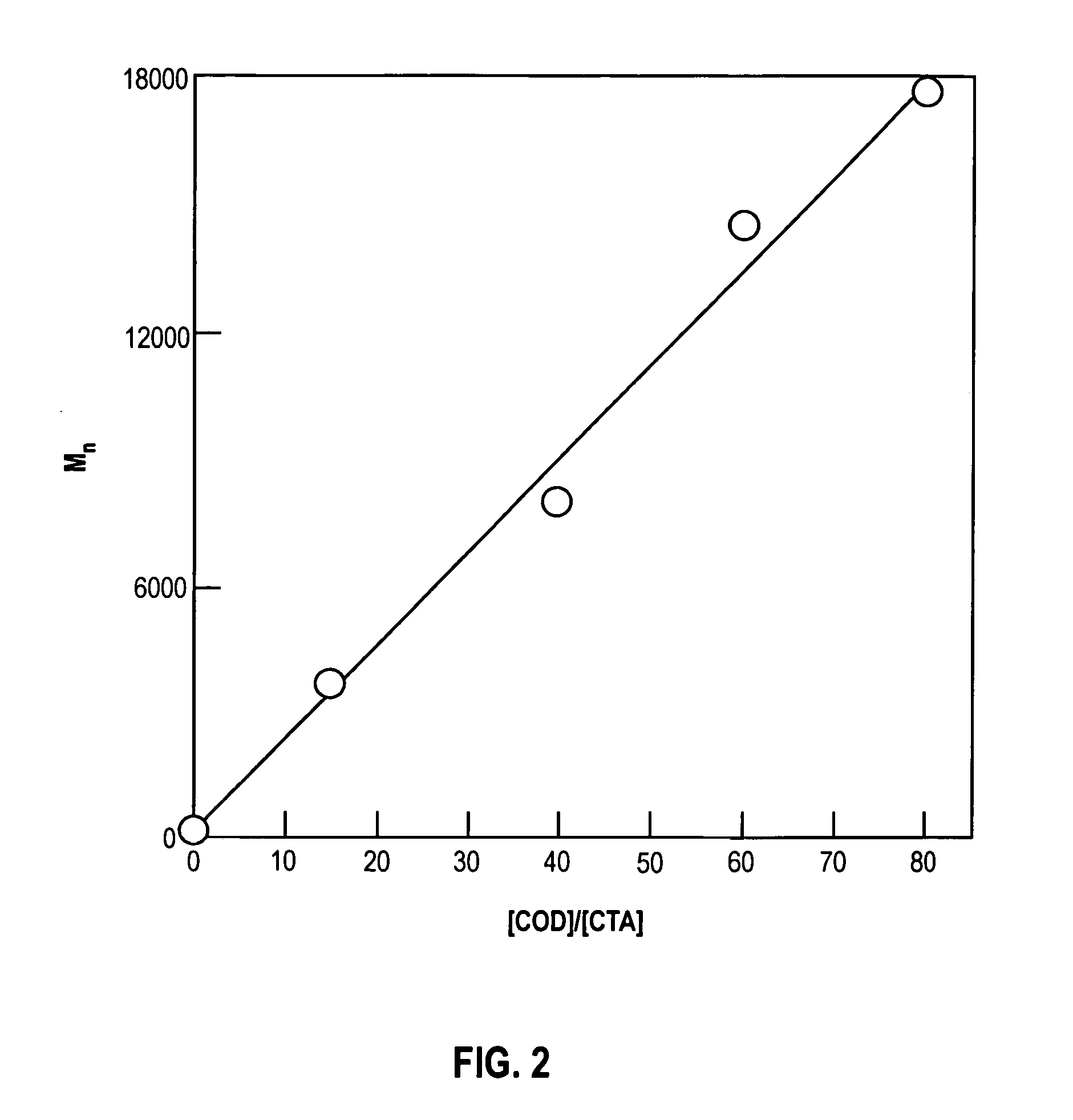

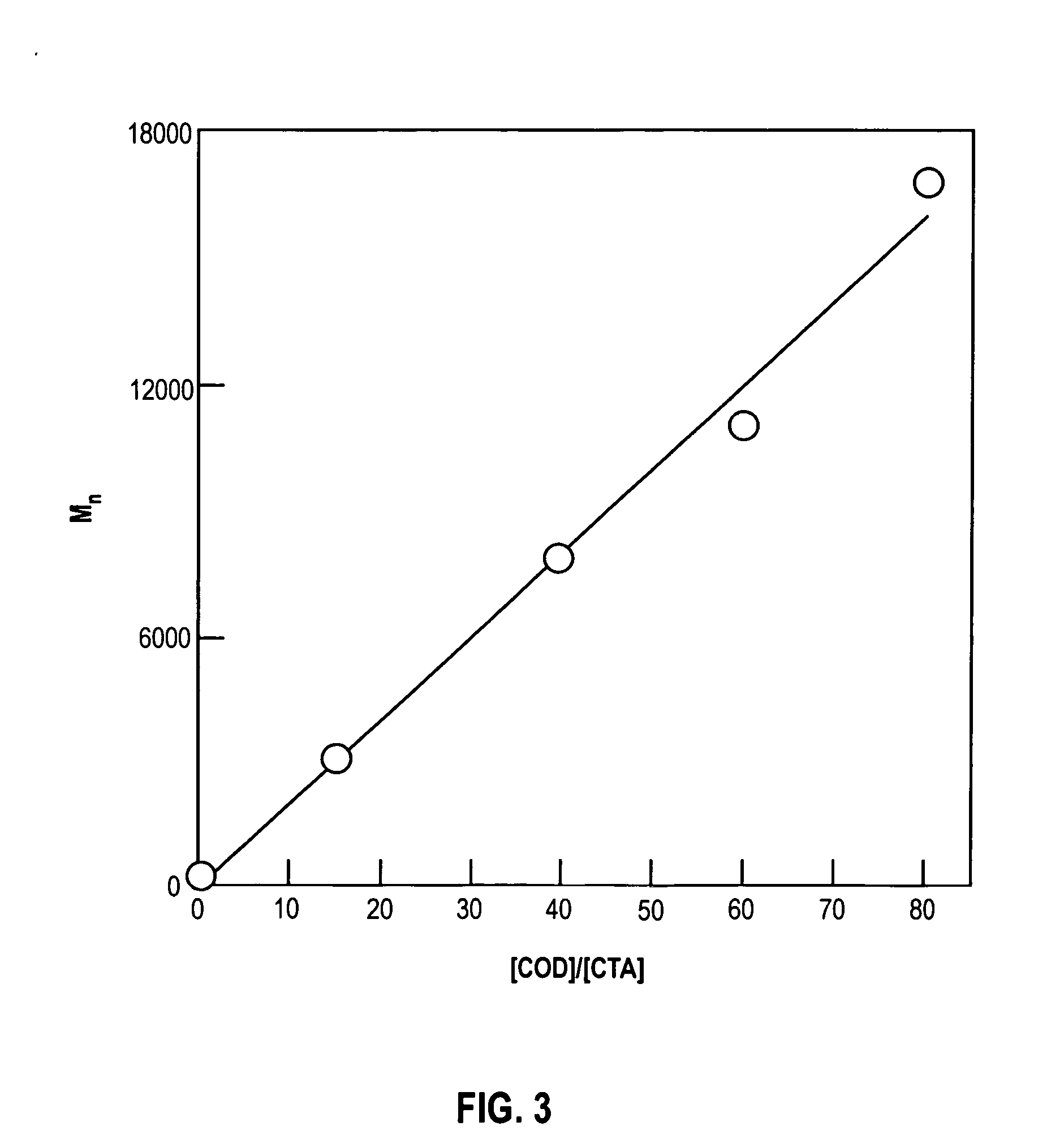

Telechelic alkadiene polymers with crosslinkable end groups and methods for making the same

The present invention relates to telechelic polymers having crosslinkable end groups of the formula and methods for preparing the same wherein n is an integer; is an alkadienyl group; Y is an alkyl group; and Z is crosslinkable end group. In general, the inventive synthesis involves reacting a functionalized chain transfer agent having crosslinkable ends with a cycloalkene in the presence of a ruthenium or osmium catalyst of the formula wherein: M is ruthenium or osmium; X and X1 are independently any anionic ligand; L and L1 are any neutral electron donor ligand; R and R1 are each hydrogen or a substituted or unsubstituted substituent wherein the substituent is selected from the group consisting of C1-C20 alkyl, C2-C20 alkenyl, C2-C20 alkynyl, aryl, C1-C20 carboxylate, C1-C20 alkoxy, C1-C20 alkenyloxy, C2-C20 alkynyloxy, aryloxy, C2-C20 alkoxycarbonyl, C1-C20 alkylthio, C1-C20 alkylsulfonyl and C1-C20 alkylsulfinyl. In another aspect of the invention, methods for controlling the molecular weight of the resulting telechelic polymer are also presented.

Owner:CALIFORNIA INST OF TECH

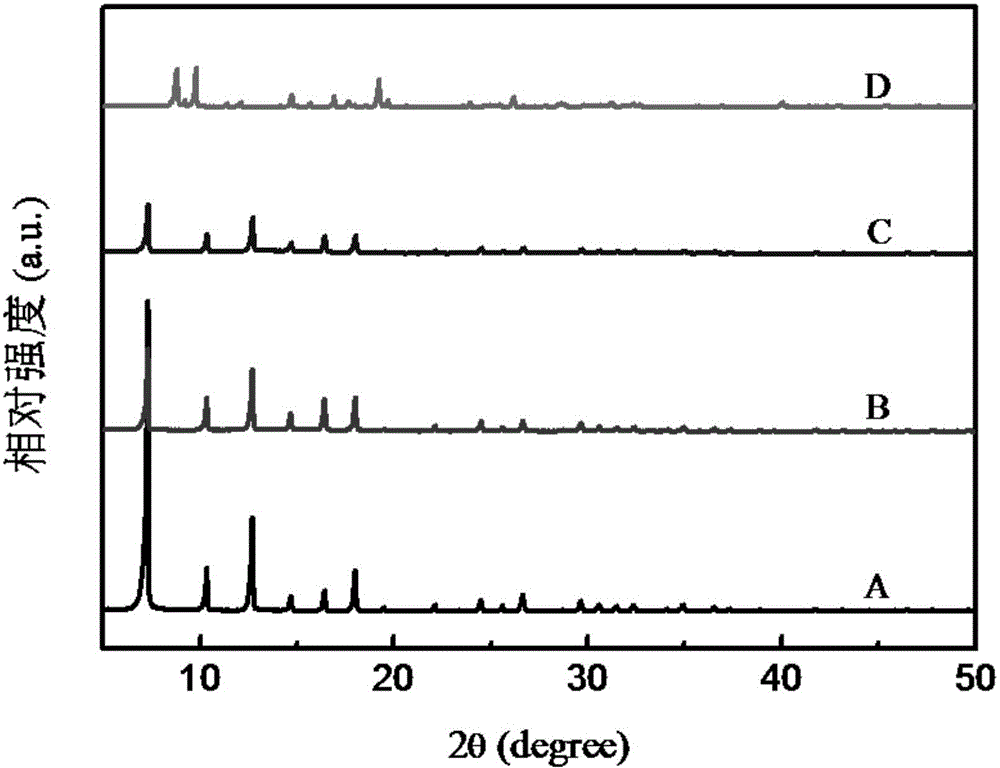

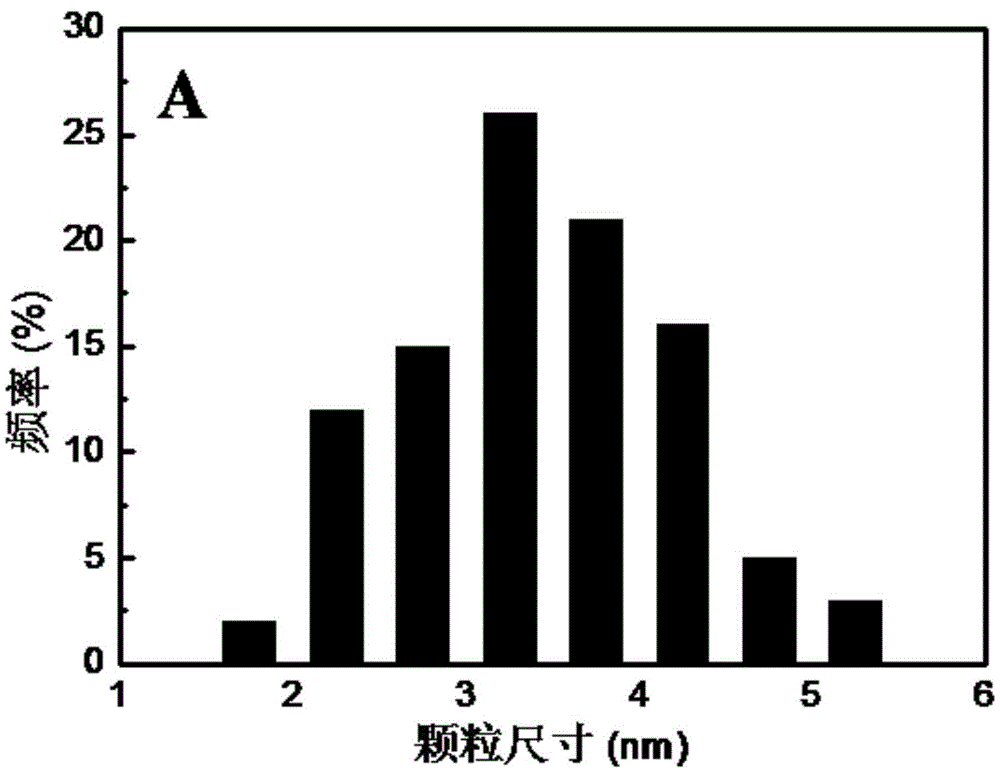

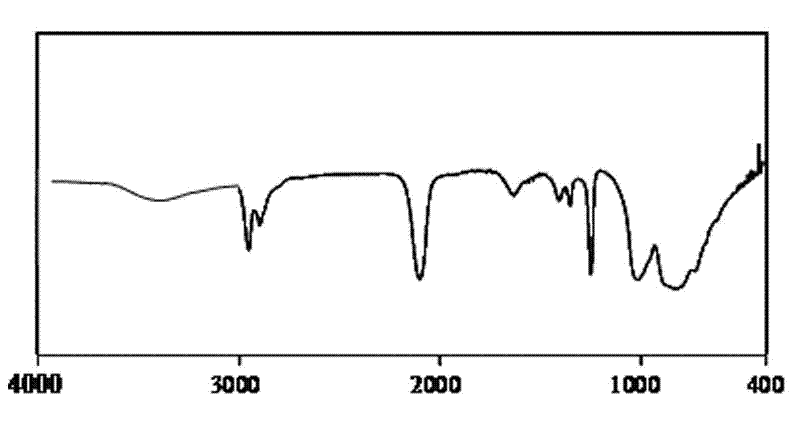

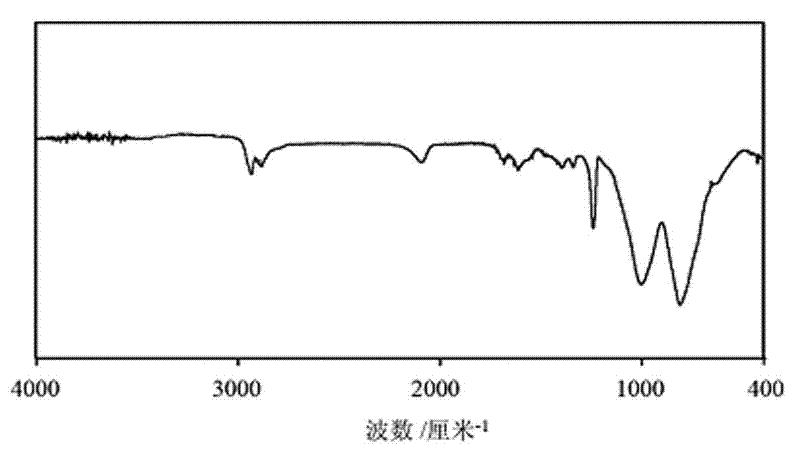

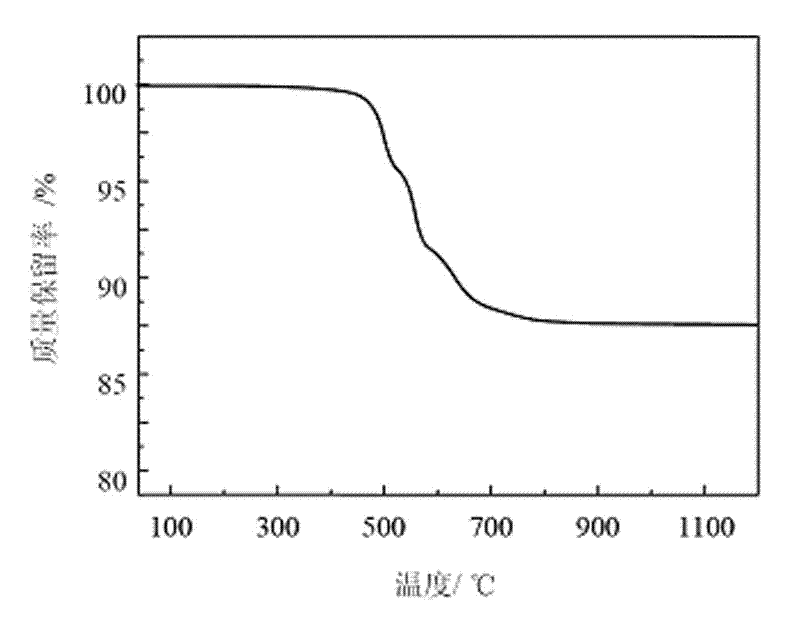

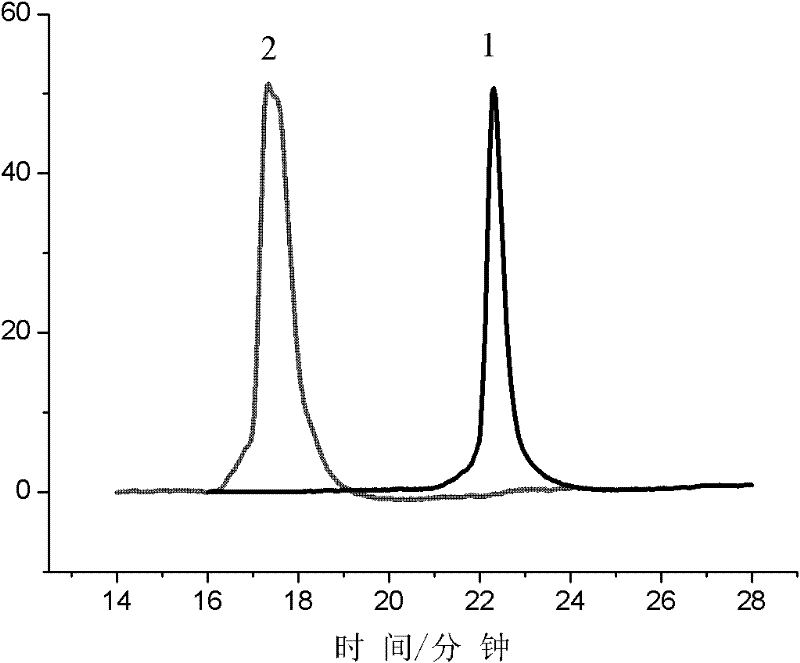

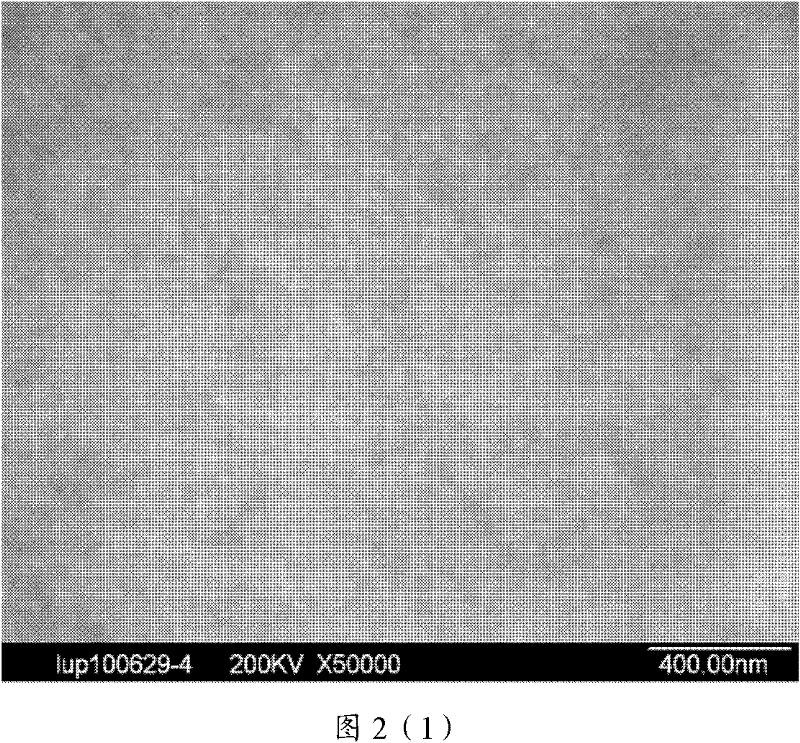

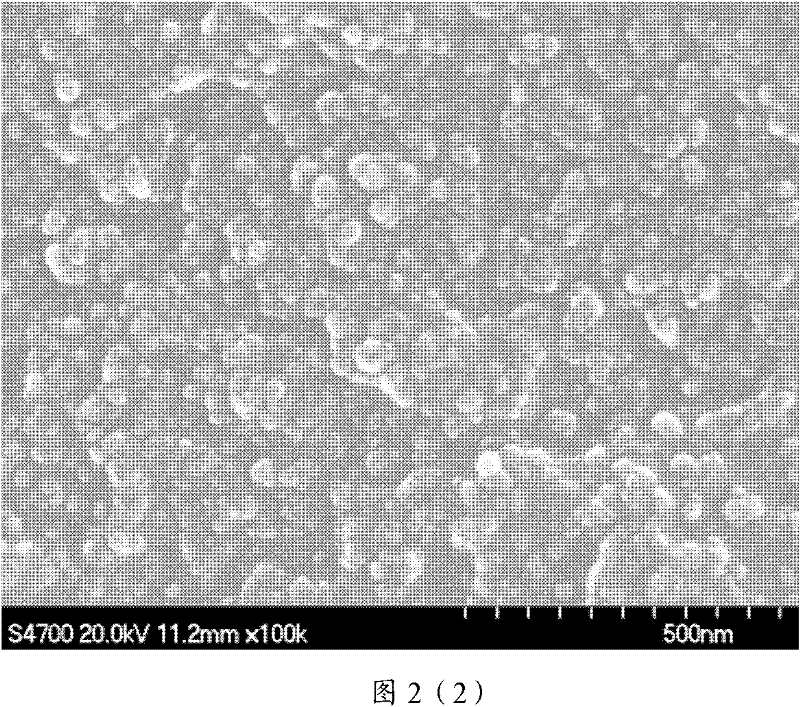

Alkadiene selective hydrogenation catalyst as well as preparation method and application thereof

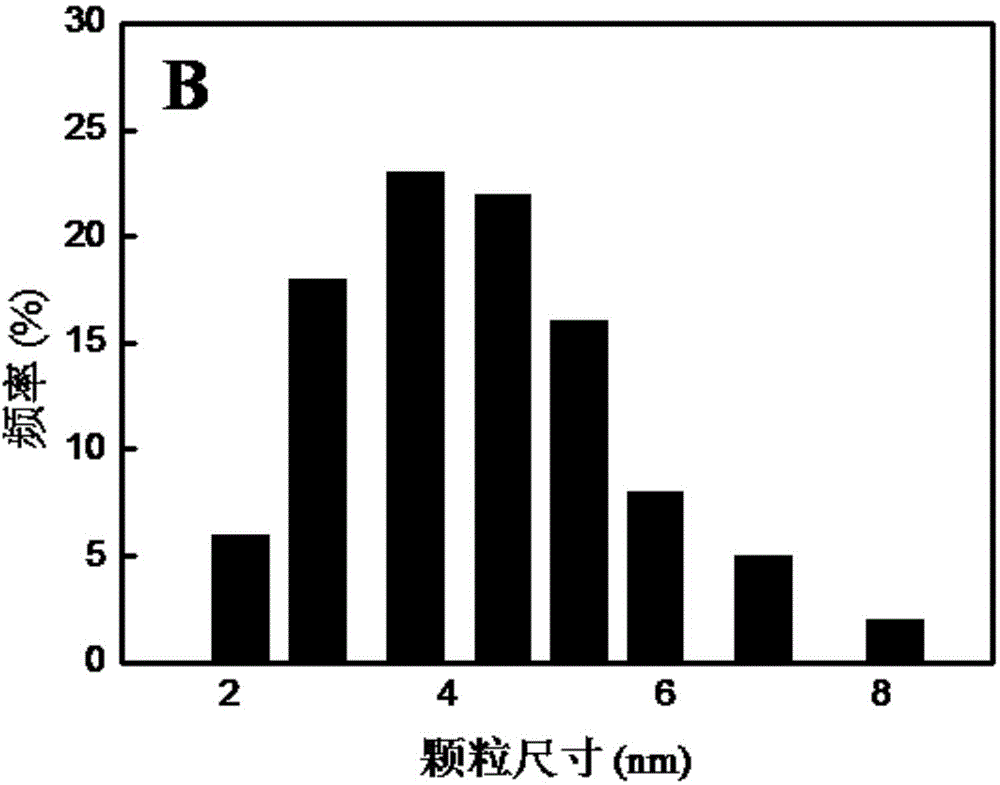

ActiveCN104399529AGood dispersionIncreased hydrogenation conversionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationActive componentReaction temperature

The invention provides an alkadiene selective hydrogenation catalyst and a preparation method thereof. The carrier of the catalyst adopts carboxyl-functionalized step hole FZIF-8; active components adopts palladium; the active component palladium accounts for 0.1 to 10 percent on the basis of the total weight of the carrier of the catalyst. The invention further provides the preparation method of the alkadiene selective hydrogenation catalyst. A step hole structure is formed in the carrier of the alkadiene selective hydrogenation catalyst, so that carboxyl groups have accessibility, and the active components and the carboxyl groups can interact mutually; the carboxyl groups are contained in the carrier of the catalyst, can anchor the active components, realize high dispersion of the active components, meanwhile prevent agglomeration and drain of the active components during the process, and ensure that the catalyst is high in activity. The catalyst can be applied to the hydrogenation upgrading of FCC petrol, removal of alkadiene in the petrol, and is mild in reaction condition, low in reaction temperature and pressure, and good in selective hydrogenation effect of products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

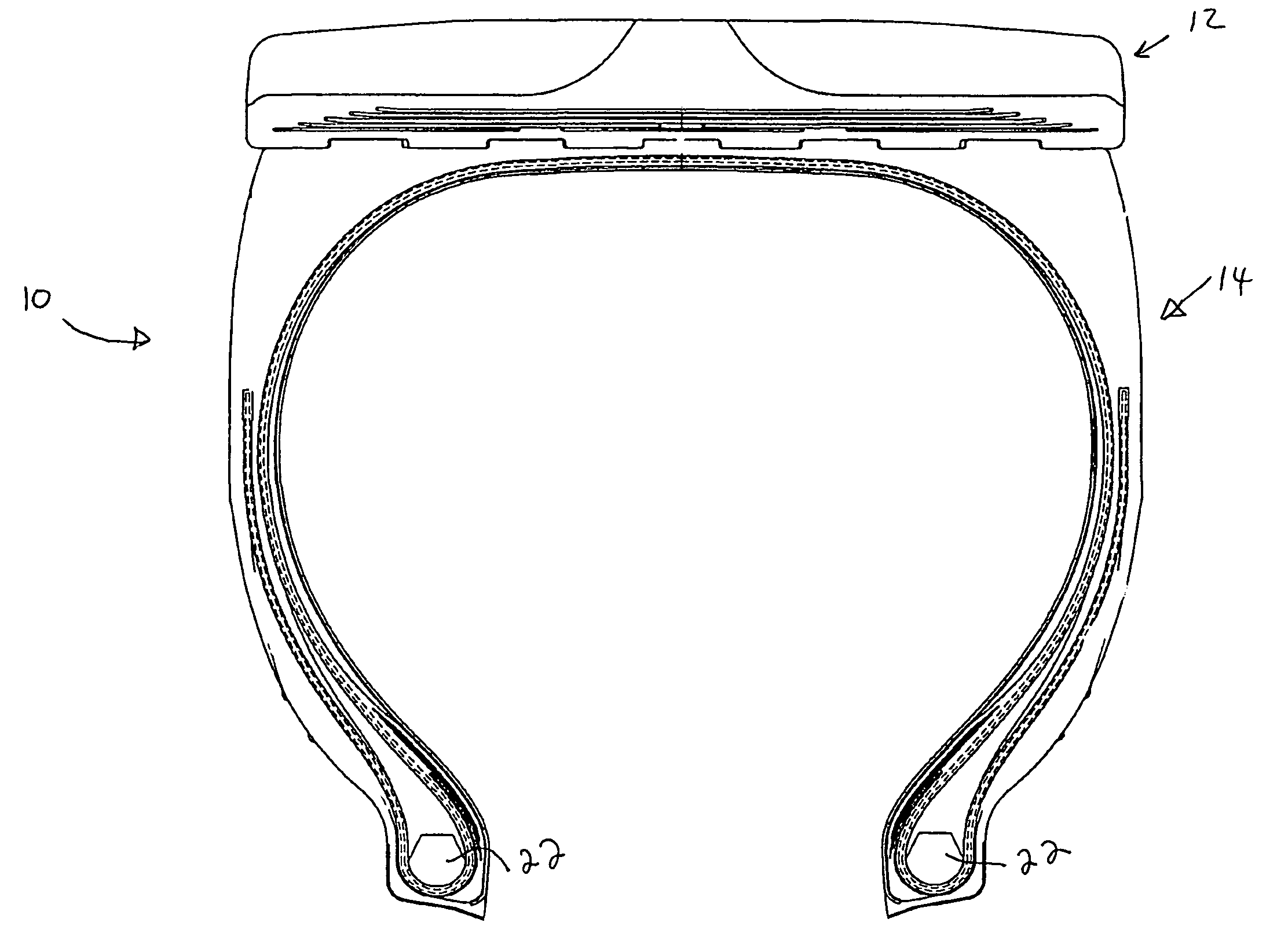

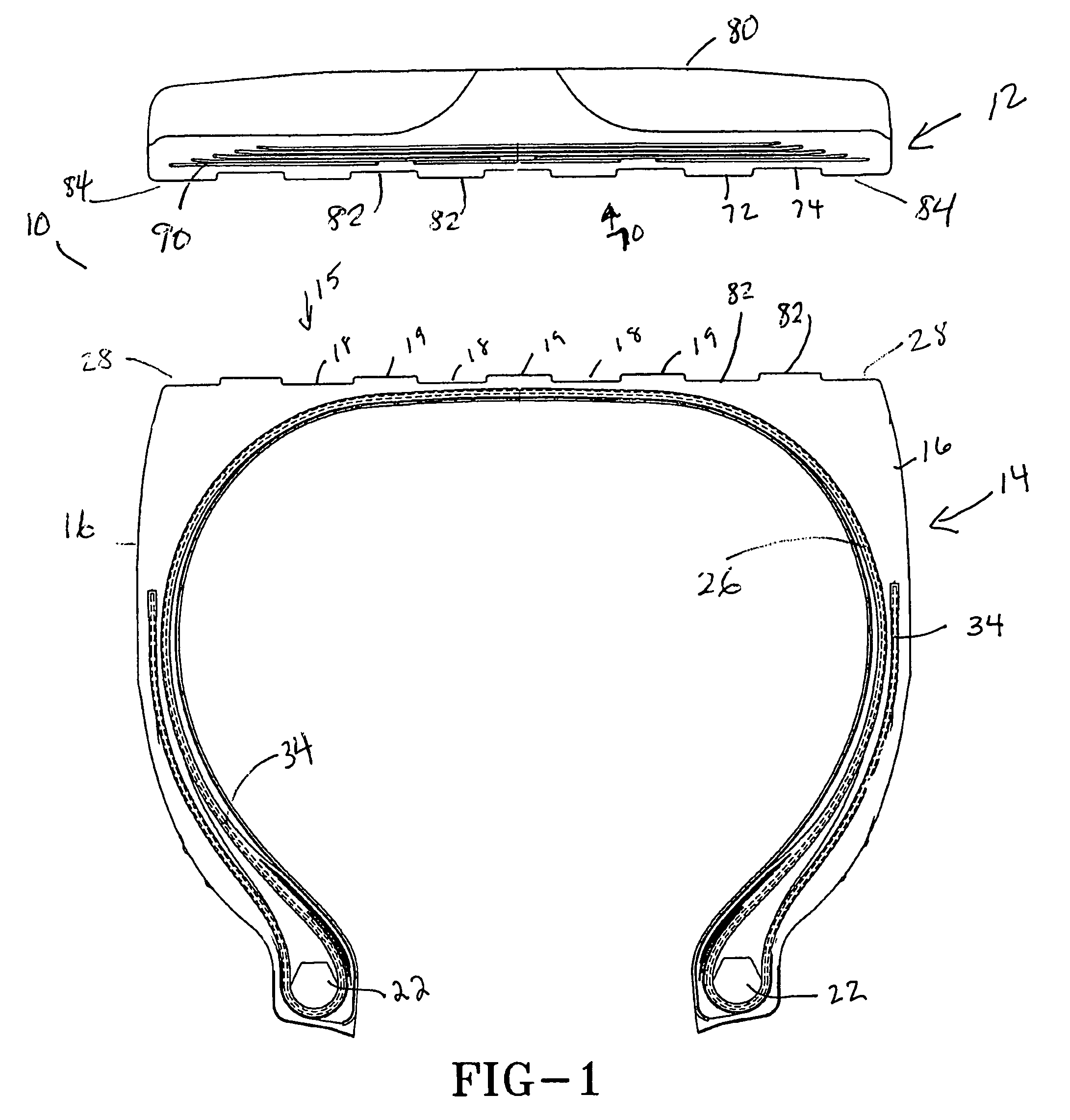

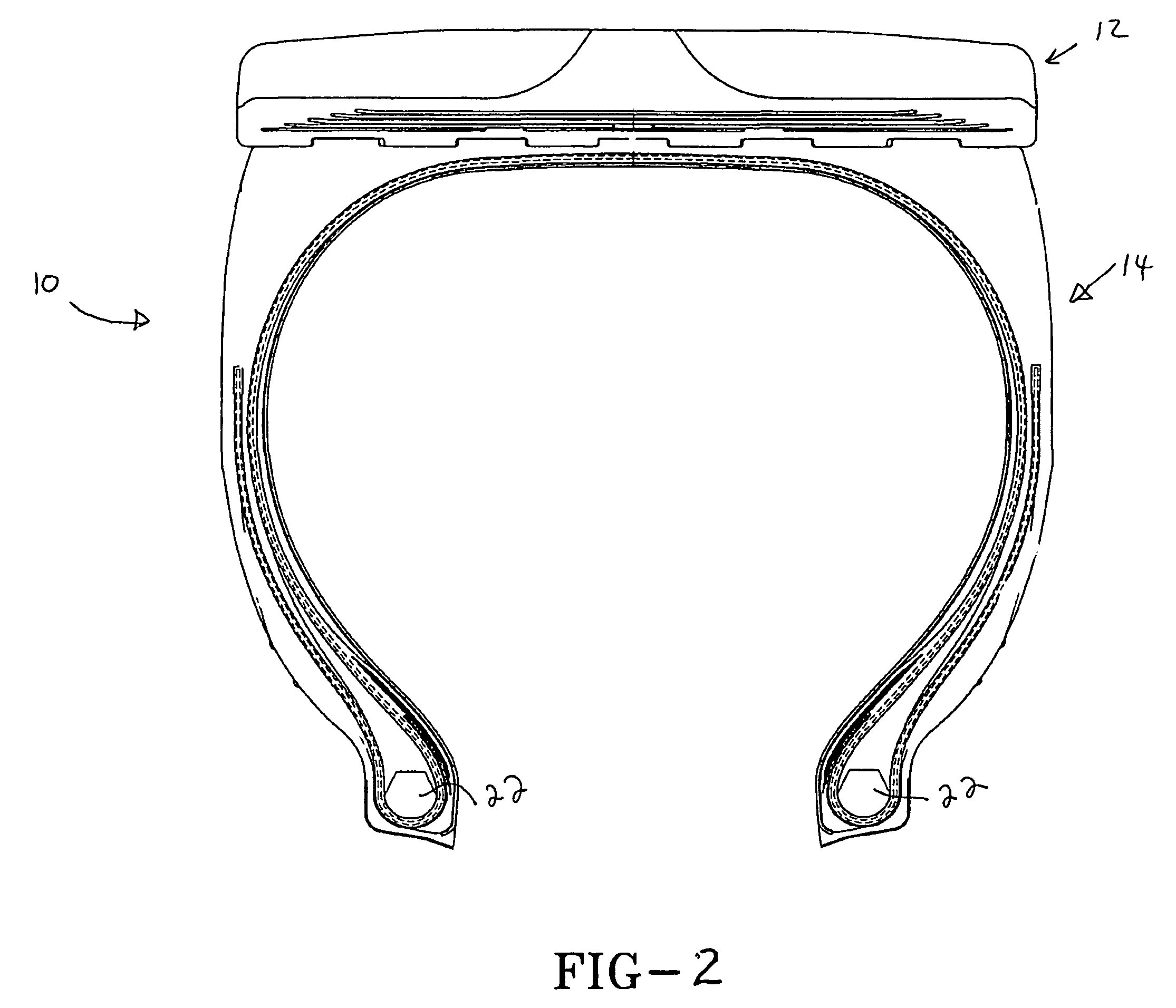

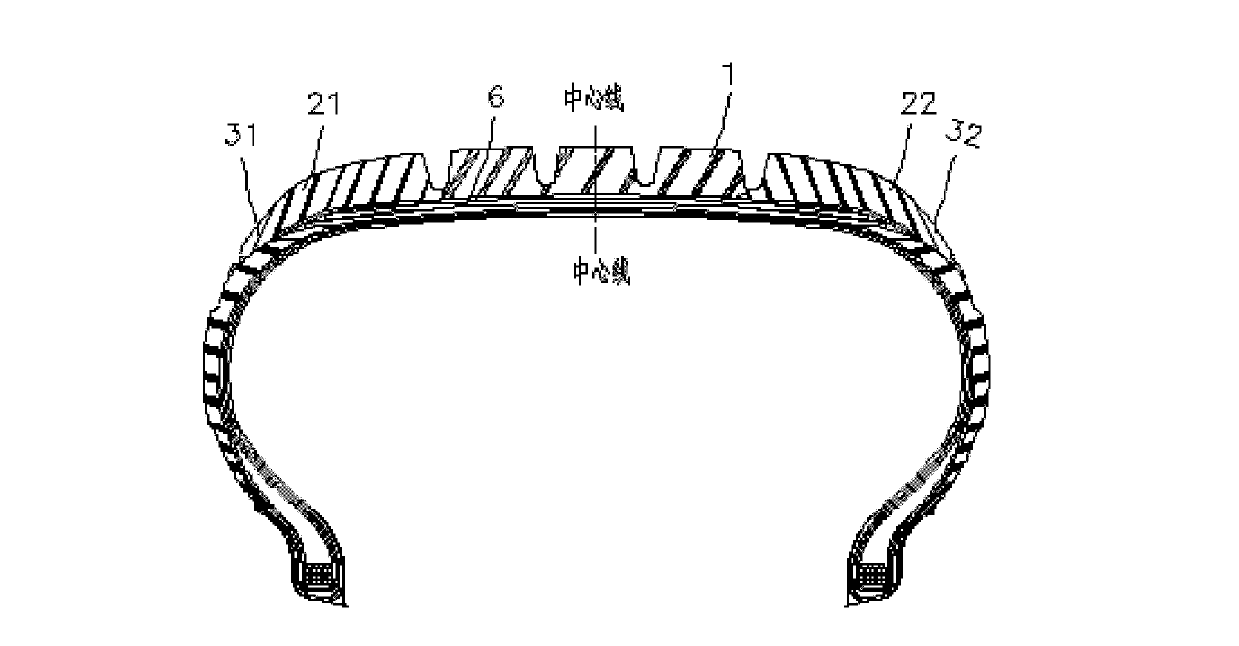

Two-piece tire

The present invention relates to a two piece pneumatic tire comprising a carcass and a removable tread belt disposed radially about the periphery of the carcass, the tread belt and carcass meeting at an interface between a radially outermost surface of the carcass and a radially innermost surface of the tread belt, wherein at least one of the radially outermost surface of the carcass and the radially innermost surface of the tread belt comprise a self lubricating rubber composition, the self lubricating rubber composition comprising at least one rubber and from 1 to 50 phr of at least one additive selected from alcohols of formula I, esters of formula II, or amides of formula IIIwherein R1 and R2 are independently selected from C12–C36 alkyl, C12–C36 alkenyl, or C12–C36 alkadienyl.

Owner:THE GOODYEAR TIRE & RUBBER CO

Preparation method of cu/stainless steel wire mesh catalyst loaded ZSM-5 molecular sieve membrane reactor

InactiveCN102274710ASurface properties can be changedConducive to loadHydrogenChemical/physical/physico-chemical processesAir atmospherePartial oxidation

The invention relates to the preparation of a catalytic material, and aims to provide a method for preparing a zeolite socony mobile-5 (ZSM-5) molecular sieve membrane reactor loaded with a Cu / stainless steel screen mesh catalyst. The method comprises the following steps of: pretreating a stainless steel screen mesh, and immersing into H2SO4 electrolyte solution to perform anodic oxidation treatment, so that a porous structure is formed on the surface of the stainless steel screen mesh; electrodepositing a Cu component on the surface of the stainless steel screen mesh; adding deionized water into a template agent, stirring at room temperature, and putting into a crystallization kettle, and immersing the Cu / stainless steel screen mesh catalyst into the solution to perform hydrothermal crystallization; and washing by using the deionized water until the solution is neutral, drying, and calcining in an air atmosphere. The ZSM-5 molecular sieve membrane reactor has the advantages of high mechanical strength, low pressure drop, high heat stability, flexible and adjustable aperture and the like, and can be used for various catalytic reactions, such as the selective hydrogenation of alkyne and alkadiene, the preparation of synthesis gas by the partial oxidation of methane, selective catalytic disproportionation of methylbenzene and the like. The novel molecular sieve membrane reactor has a wide application prospect in processes of catalysis, separation and the like.

Owner:ZHEJIANG UNIV

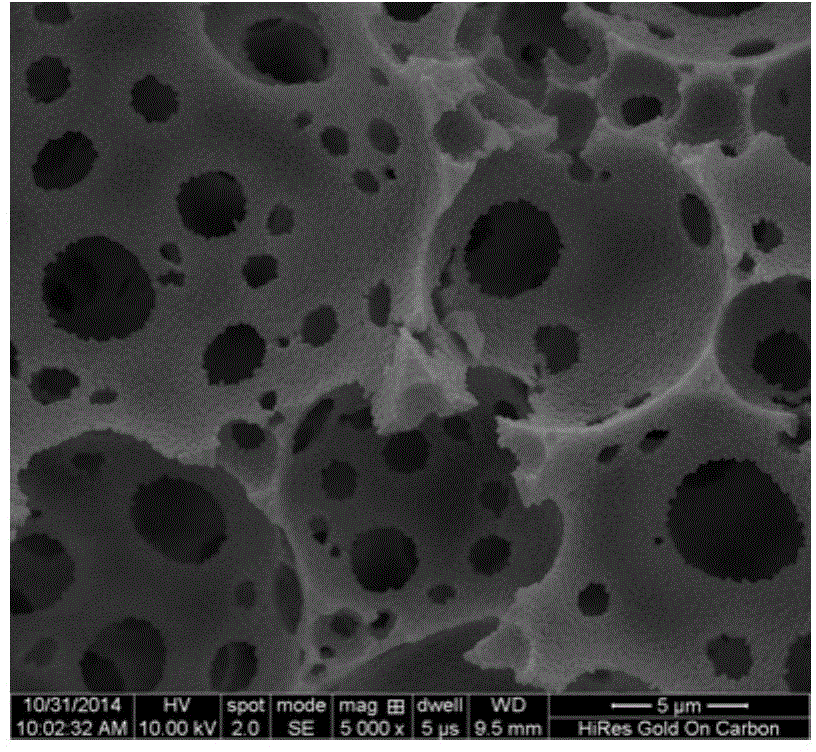

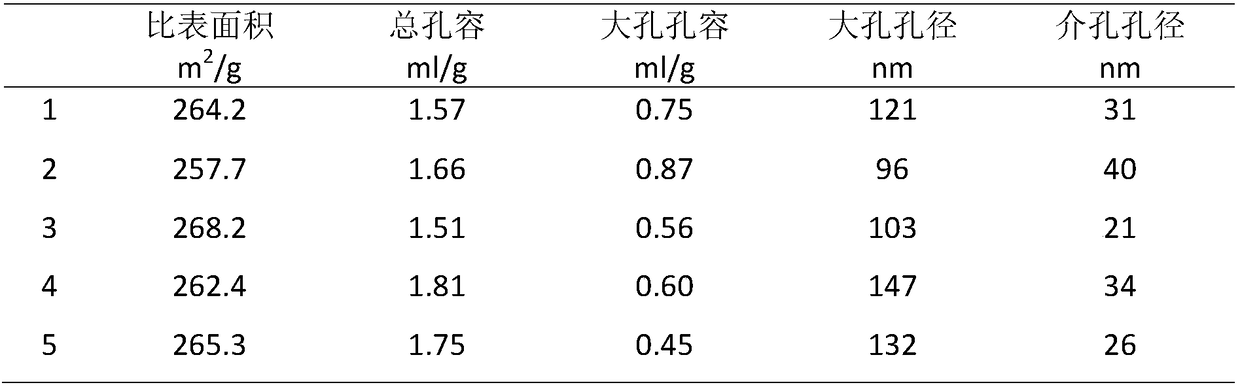

High-superficial-area porous adsorption material and preparation method and application of high-superficial-area porous adsorption material

InactiveCN104437430ALow densitySmall sizeOther chemical processesEnergy based wastewater treatmentFoaming agentAlcohol

The invention relates to a high-superficial area porous adsorption material and a preparation method and application of the high-superficial-area porous adsorption material. The method comprises the following steps: mixing 1-10 parts of a PEI amphipathic body, 30-70 parts of olefin / alkadiene, 10-30 parts of a pore-foaming agent and 1 part of a radical initiator as an oil phase; dropping water, which is equal to 8-9 times of volume of the oil phase, and of which the pH is 7-9 into the oil phase under stirring, so as to form emulsion; further stirring, and then hatching at 60-80 DEG C for 5-24 hours; and washing with low alcohols so as to obtain porous solid, and drying, so as to obtain the high-superficial area porous adsorption material. Compared with the prior art, the porous adsorption material disclosed by the invention can adsorb anionic organic matter such as various dyes and phenol in water, so that the typical residual concentration is respectively reduced to below millionth. Due to small density and large size, the high-superficial area porous adsorption material can be easily separated out from water; and the adsorbent can be regenerated through alkali treatment.

Owner:TONGJI UNIV

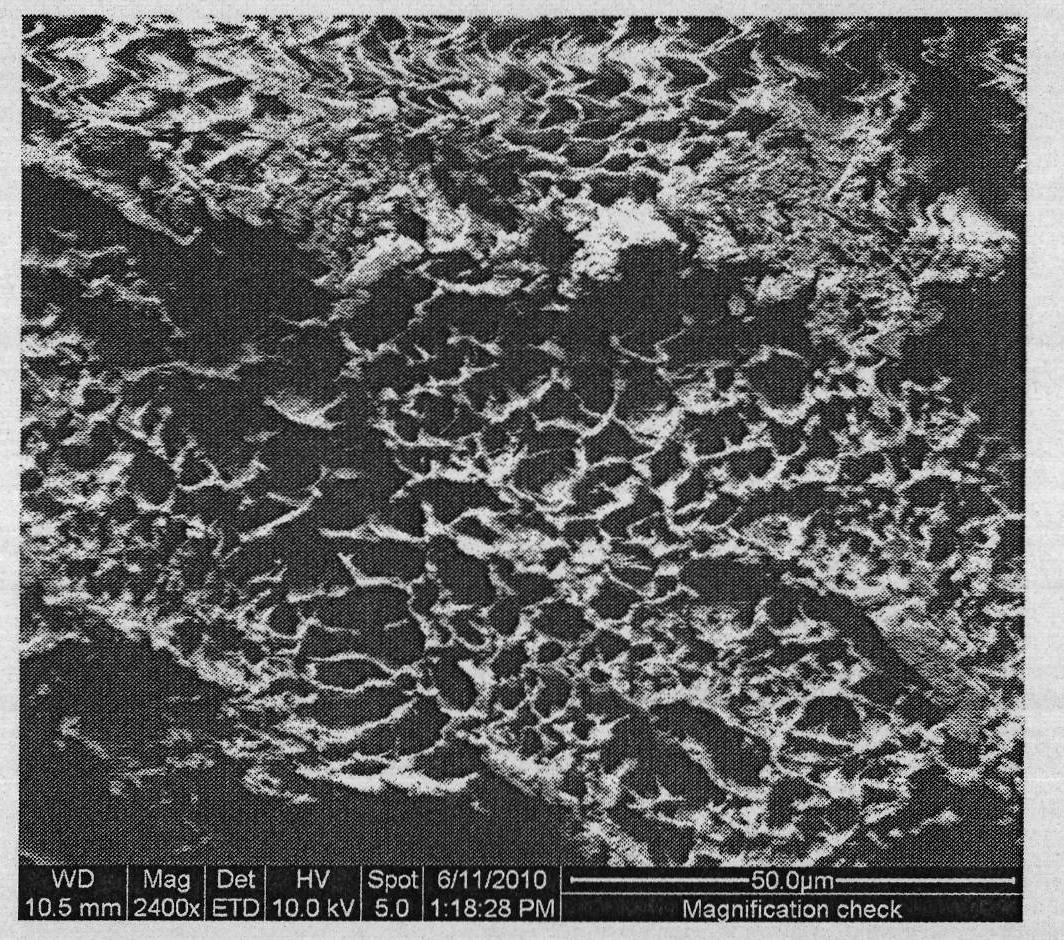

Catalytic crosslinking method for polycarbosilane fiber

ActiveCN102586953AAvoid introducingLow reaction temperatureSynthetic polymer filament chemical after-treatmentFiberFibril

The invention discloses a catalytic crosslinking method for polycarbosilane fiber. The catalytic crosslinking method comprises the following steps of: catalytic solution preparation: taking 0.1-0.3g of catalyst noble metal compound to dissolve in 100mL of deionized water or ethanol; causing polycarbosilane fibril to pass through a catalyst aqueous solution slot, or spraying catalyst ethanol solution onto the polycarbosilane fibril through a spraying method, and drying; arranging the polycarbosilane fibril (which is obtained in step two) containing the catalyst noble metal compound into a chemical gaseous phase crosslinking system, vacuumizing, exchanging gas in a kettle by nitrogen to normal pressure, and repeating for 2-4 times; introducing alkadiene or alkyne; conducting programmable heating to 50-250DEG C, and reacting for 0.5-12h; and heating to 350-500DEG C, keeping warm for 0.5-2h, and cooling to the room temperature to obtain the polycarbosilane fiber. The catalytic crosslinking method has simple and convenient technology and low cost and is suitable for large-scale production.

Owner:NAT UNIV OF DEFENSE TECH

Method for improving gasoline quality by etherifying light gasoline

ActiveCN105623735AImprove simplicityGood reproducibilityTreatment with hydrotreatment processesHydrocarbon oils treatment productsGasolineAlkene

The invention discloses a method for improving the gasoline quality by etherifying light gasoline. The method comprises the following steps: (1) separating and hydrogenating catalytic gasoline to obtain alkadiene-removed light gasoline; (2) washing the alkadiene-removed light gasoline to remove toxins in an etherified catalyst in the light gasoline, and dehydrating; (3) leading the dehydrated light gasoline in the step (2) and ethanol to enter the etherifying reaction part, flowing the reactant from a reactor to obtain effluent which is mixture of TAME, C5 component and ethanol; and (4) introducing the mixture of TAME and C5 component in the step (3) into a liquid distribution device, discharging from the liquid distribution device after liquid distribution and moisture removal to obtain the high-quality clean gasoline. The method can be used for greatly improving the environmental friendliness and reducing sewage discharge, has the advantages of simplicity in operation, high active olefin conversion rate and the like, and enables the conversion rates of active C5 and active C6 olefin to be over 90 percent and 45 percent respectively.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

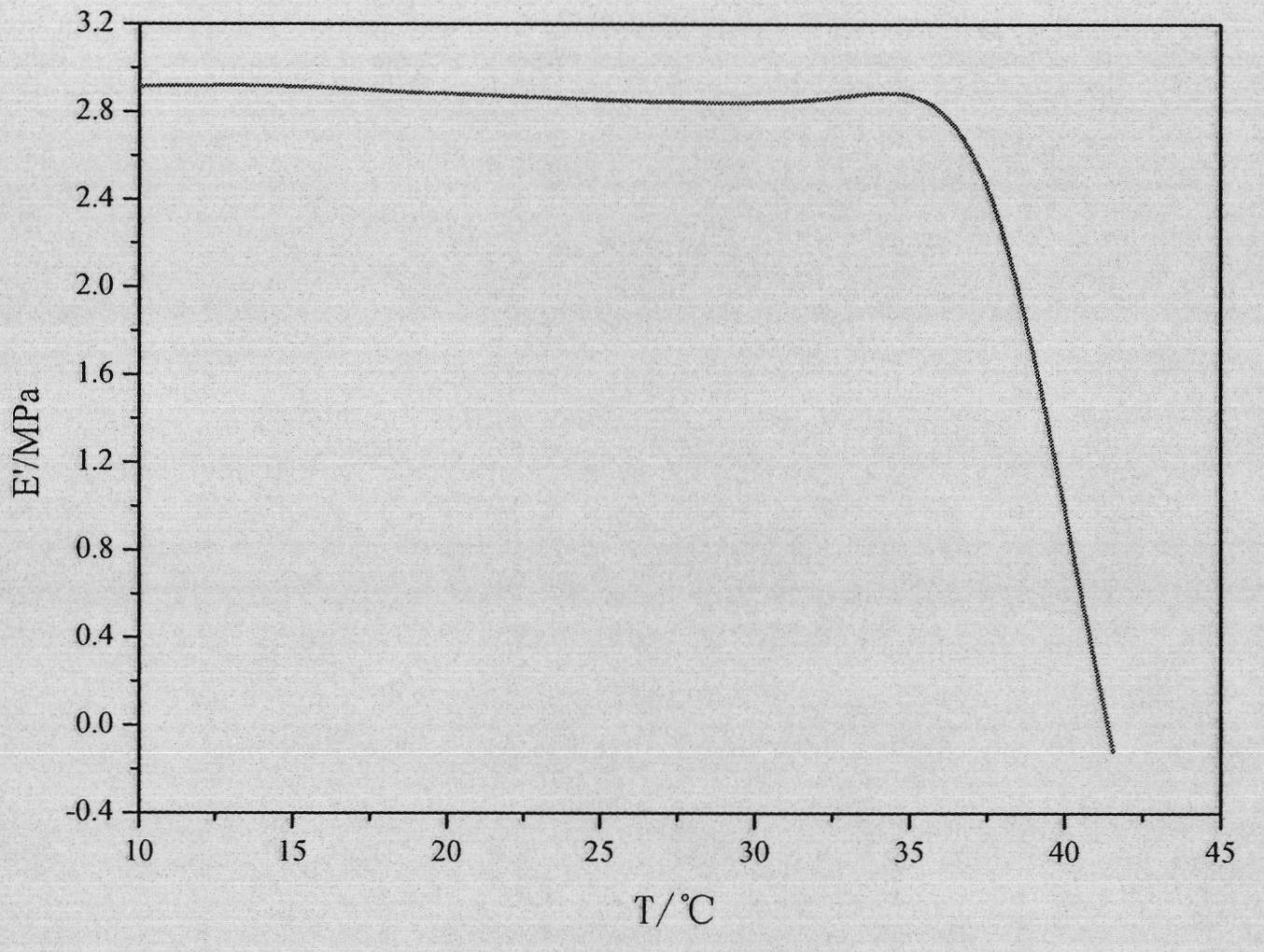

Liquid crystal-enhanced fast response temperature sensitive hydrogel and preparation method thereof

The invention relates to a liquid crystal-enhanced fast response temperature sensitive hydrogel and a preparation method thereof. The hydrogel contains the following three components in percent by weight: 10-58 percent of amphiphilic liquid crystal molecule polyoxyethylene fatty alcohol ether M1, 2-10 percent of alkadiene M2 both ends of which contain double bonds and 40-80 percent of alkyl acrylamide M3 with temperature sensitivity. In the preparation method, by taking the Mi as a temperature in an aqueous solution, liquid crystal molecules are removed through soaking after the polymerization is ended to obtain the hydrogel with fast temperature response and mechanical property. The hydrogel is transparent to milky in appearance, and the internal hole dimensions are 1-10 mu m. The method has simple preparation process, is easy to control and can be used for manufacturing various shapes of hydrogel; and the temperature sensitivity and the mechanical property of the hydrogel can be regulated through changing the density, the water content and the components of a cross-linking agent. The hydrogel can be used for the fields of biology, sensing and the like.

Owner:TIANJIN POLYTECHNIC UNIV

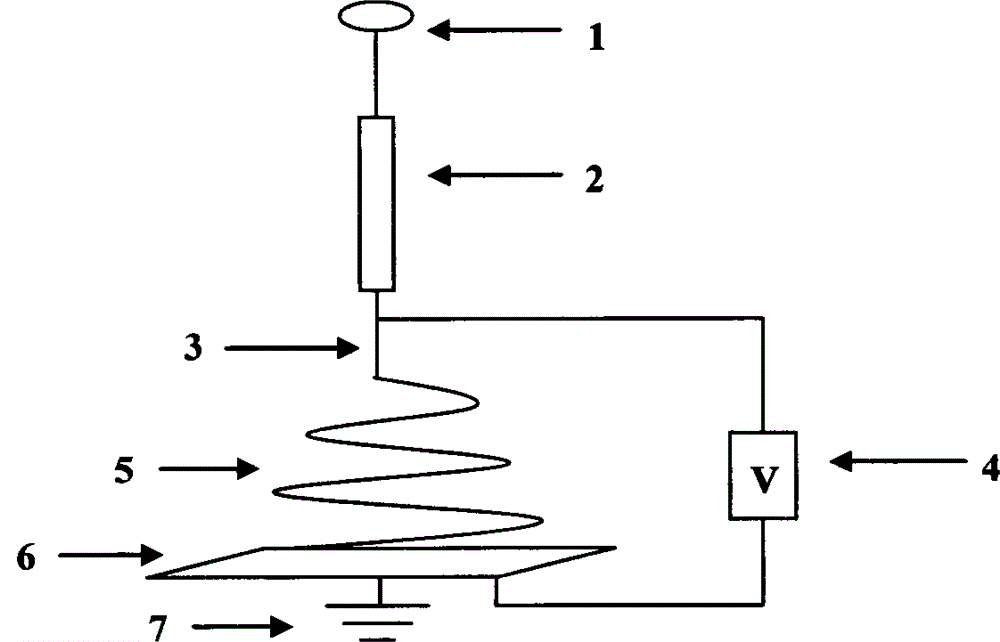

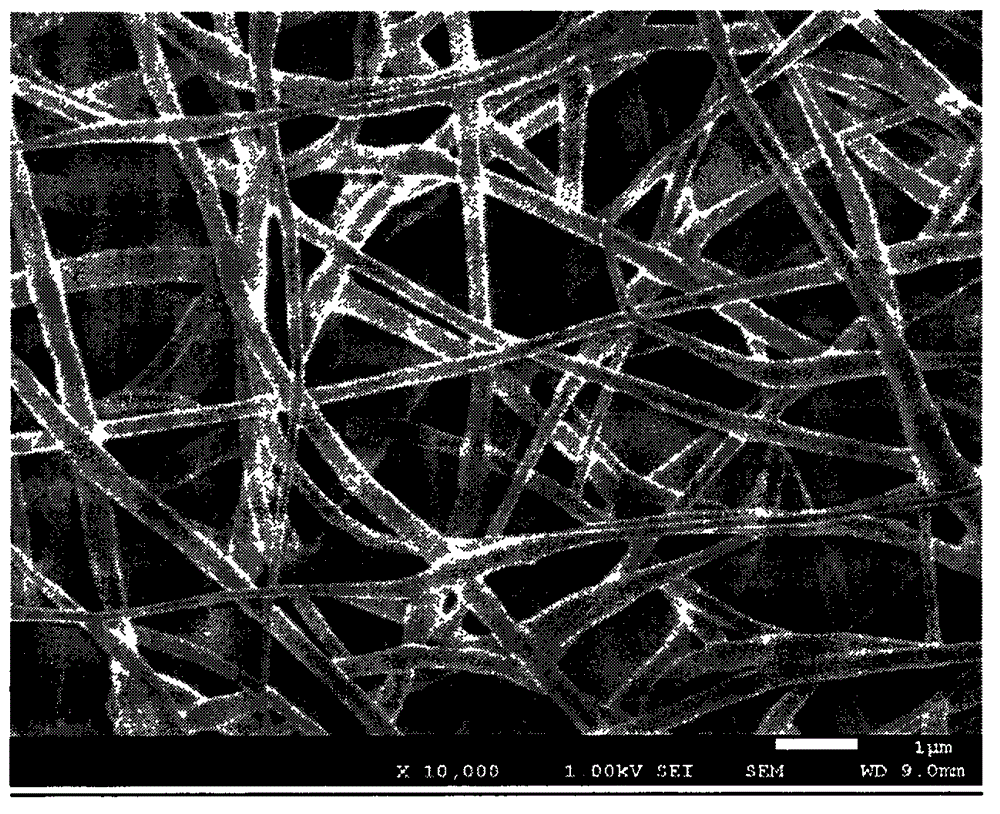

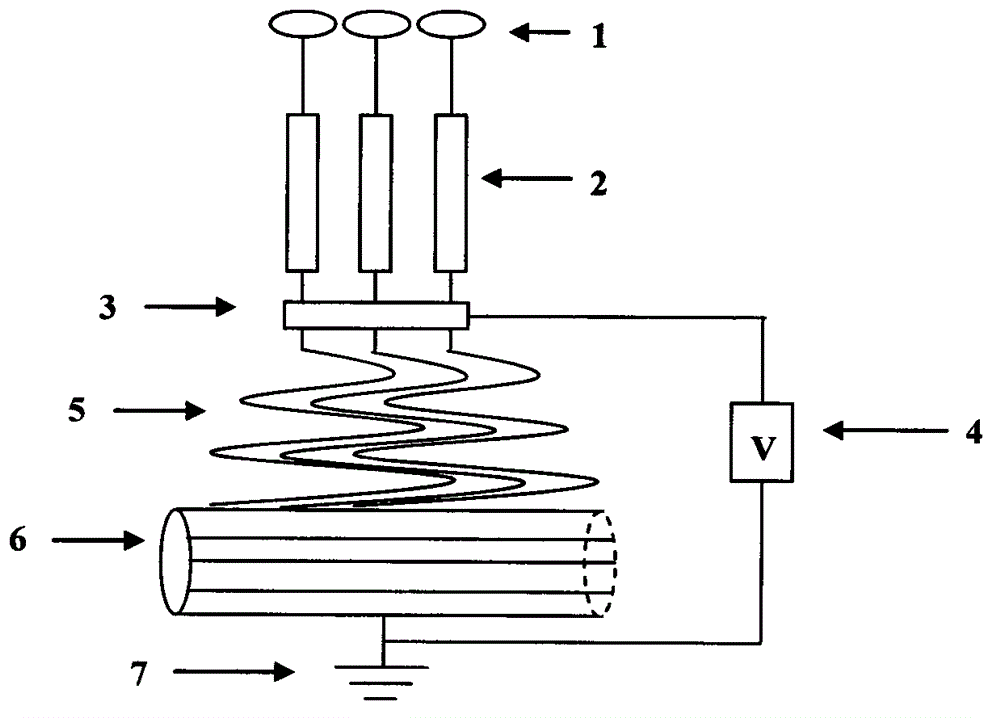

Trans-rubber fiber material, preparation method and applications thereof

InactiveCN103911766AControl diameterControl speedNew-spun product collectionFilament/thread formingFiberPorosity

The invention provides a trans-rubber fiber material. The trans-rubber is selected from one or more of trans-1, 4-polyisoprene, trans-1, 4-polybutadiene, trans-1, 4-butadiene-isoprene copolymerization rubber, trans-1, 4-butadiene-piperylene copolymerization rubber, trans-1, 4-polydiolefin rubber alloy and trans-1, 4-alkadiene homopolymer and / or homopolymer epoxidation or chlorination modified derivatives and derivatives. The diameter of the trans-rubber is in a range of 100nm to 10 microns. The invention further provides a preparation method and applications of the trans-rubber fiber material. The trans-rubber fiber material has the advantages of being fine in diameter, low in weight, large in specific surface area, large in porosity, small in mass-to-volume ratio, capable of maintaining good fiber morphology after being put for a period and free of fiber dissolving and deformation of other fibers in the prior art.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for preparing catalyst of rare earth butadiene rubber

The invention relates to a preparation method for preparing a catalyst of rare earth butadiene rubber. The preparation method comprises the following steps: under nitrogen protection, successively adding a solution of a phosphoric acid rare earth compound, alkadiene and hydrogenated aluminum alkyl into a catalyst ageing bottle which is dried; ageing the mixture for 10-30min at 0-60 DEG C; then adding an organic chloride; ageing the mixture for 5-20min at 0-60 DEG C to from a homogeneous transparent solution; and then adding aluminum alkyl to age for 1-30min at 0-60 DEG C to prepare the catalyst of rare earth butadiene rubber. The catalyst is used for evaluating activity of butadiene polymerization. The monomer conversion rate is greater than or equal to 90%, the Mooney point of a product is 55-100, the number-average molecular weight is greater than or equal to 180 thousand and the molecular weight distribution is 1.3-2.5.

Owner:PETROCHINA CO LTD

Tire with low rolling resistance

ActiveCN103374154AImprove wear resistanceExtend the life cycleSpecial tyresRolling resistance optimizationElastomerRolling resistance

The invention provides a tire with low rolling resistance. The abrasion resistance of the tire is improved. The rolling resistance coefficient of the tire is smaller than 10.5kg / t. The tire comprises a tire tread which has a split-type structure and consists of a tire crown, a tire shoulder and a tire side, wherein the tire shoulder consists of the following rubber compositions in percentage by weight: 0-30 percent of cis alkadiene elastomer, 15-50 percent of copolymerization olefin polymer, 8-30 percent of carbon black, 10-40 percent of white carbon black and 3.5-35 percent of rubber additive. The tire shoulder of the tire with the low rolling resistance provided by the invention consists of the rubber compositions comprising 8-30 percent of carbon black; by the carbon black, the abrasion resistance of the tire shoulder is improved, the whole use cycle of the tire is prolonged, and the service life of the tire is prolonged. The tire provided by the invention also has low rolling resistance, good wetland road holding capacity and high abrasion resistance.

Owner:CHENG SHIN RUBBER CHINA

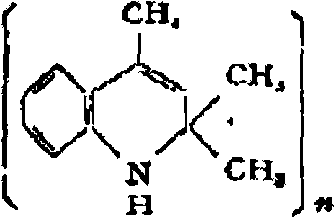

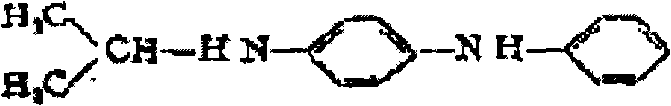

Rubber composition

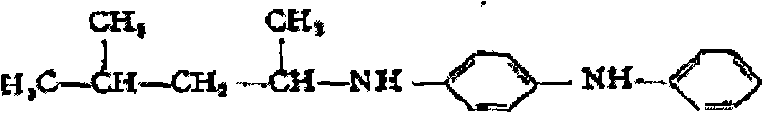

The invention provides a rubber composition. According to the invention, low-cost alkadiene rubbers are adopted, such as natural rubber (NR) and isoprene rubber (IR); a single alkadiene rubber component can be used, and a combination of two or more than two alkadiene rubber components can also be used; an anti-aging agent used in the rubber composition meets the requirements of European Union REACH environmental protection law, and the rubber composition contains high-content anti-aging active components; an accelerating agent used in the rubber composition can generate fewer nitrocompounds, and the processing property and mechanical property of the rubber composition are equivalent to those of the rubber composition in which a common anti-aging agent and a common accelerating agent are used. The invention simultaneously provides a pneumatic tyre using the rubber composition as a material. Specifically, the invention relates to a rubber composition which comprises a rubber component containing diene rubbers, an environment-friendly anti-aging agent and an environment-friendly accelerating agent; and the invention further relates to a pneumatic tyre using the rubber composition as a material.

Owner:CHINA PETROLEUM & CHEM CORP +1

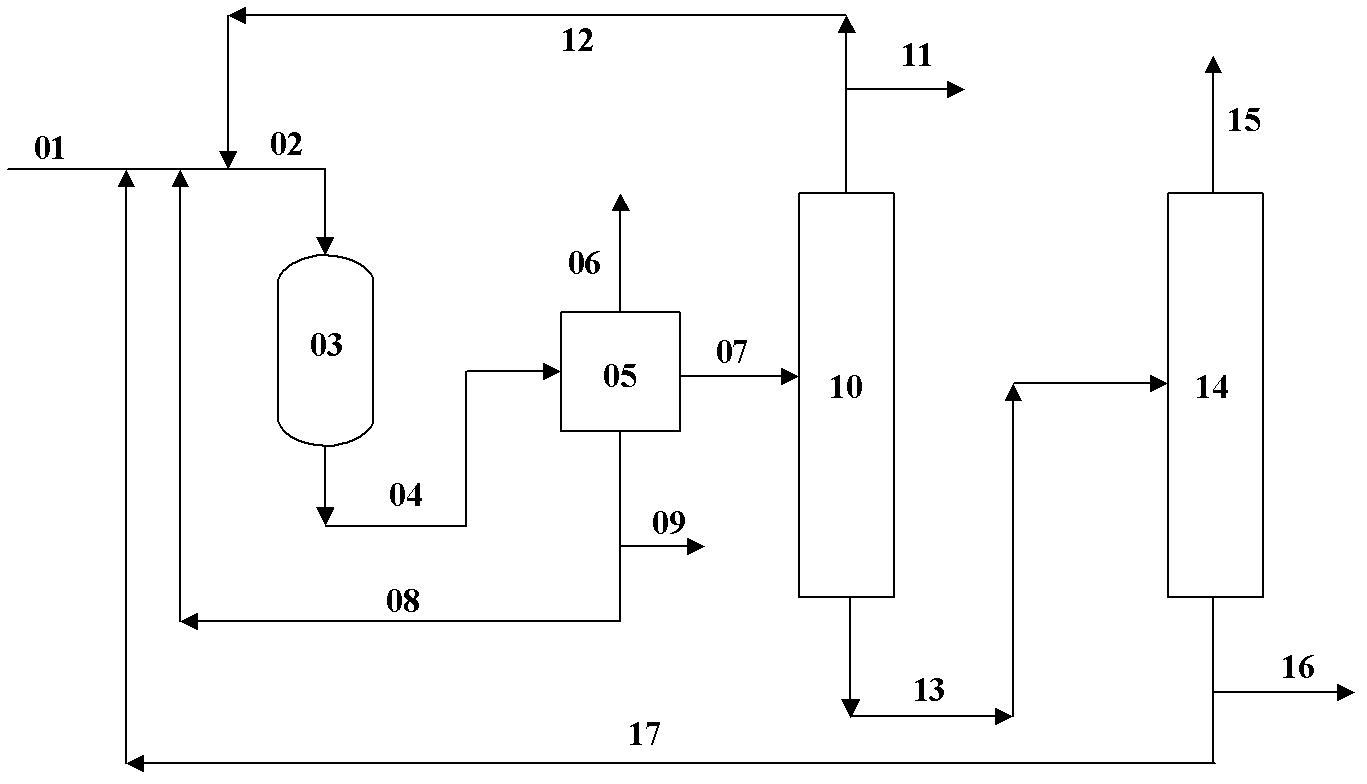

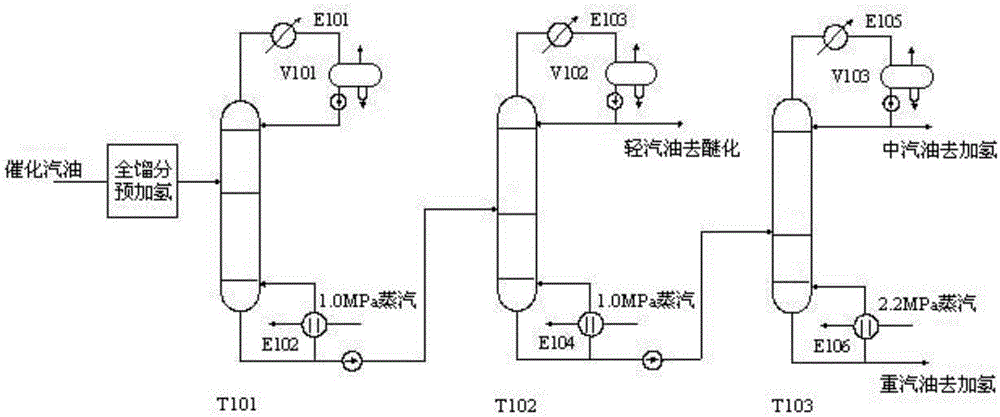

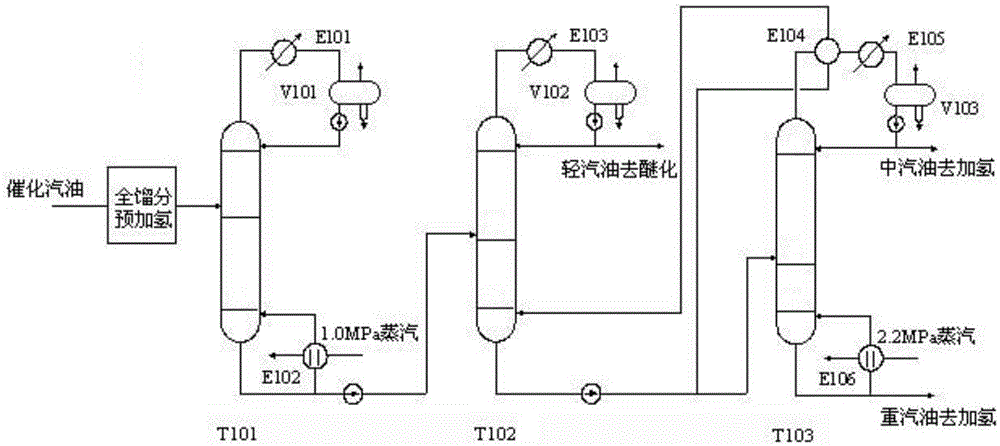

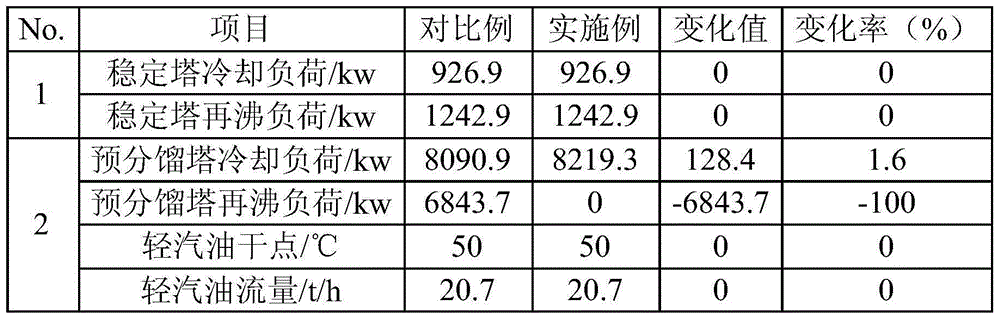

Novel process for reducing energy consumption of catalytic gasoline hydrogenation refining process

InactiveCN105062559AEliminate consumptionReduce cooling loadTreatment with hydrotreatment processesHydrogenGasoline

The invention belongs to the technical field of petrochemical engineering and discloses a novel process for reducing energy consumption of a catalytic gasoline hydrogenation refining process. The process comprises the flows: removing alkadiene in catalytic gasoline from a catalytic cracking device by virtue of a whole fraction prehydrogenation device, and then feeding a whole fraction reactant into a stabilizing tower to separate light hydrocarbon less than or equal to C4 and excessive hydrogen; feeding stable gasoline at the bottom of the stabilizing tower into a prefrationation tower to separate light gasoline to be de-etherized, wherein the tower top pressure of the prefractionation tower is 0.07MPag, and the tower bottom temperature is 124.4 DEG C; feeding the pump-pressurized circulating material flow at the bottom of the prefractionation tower into a heat exchange at the top of a heavy cut tower; after heat removal, turning heat to the tower bottom, wherein the tower top temperature of the heavy cut tower is 0.56Mpag and the tower top temperature is 156.0 DEG C; and finally, feeding the prefrationated gasoline at the tower bottom of the prefrationation tower into the heavy cut tower to be divided into medium gasoline and heavy gasoline, and separately feeding the medium gasoline and the heavy gasoline to hydrogenation sections in different reaction depths. The process disclosed by the invention can be used for reducing energy consumption to a great extent and has a good energy-saving benefit.

Owner:SOUTH CHINA UNIV OF TECH

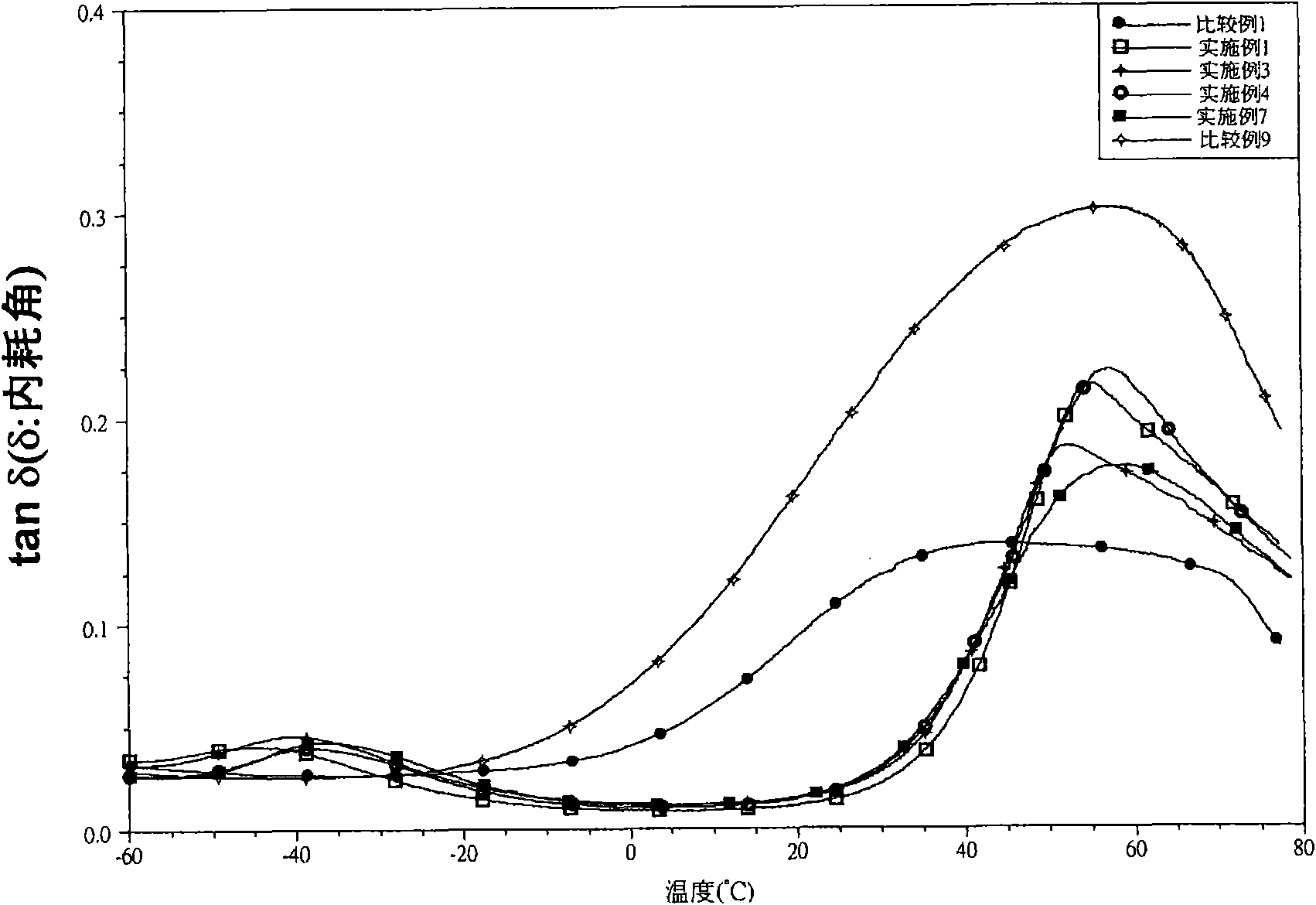

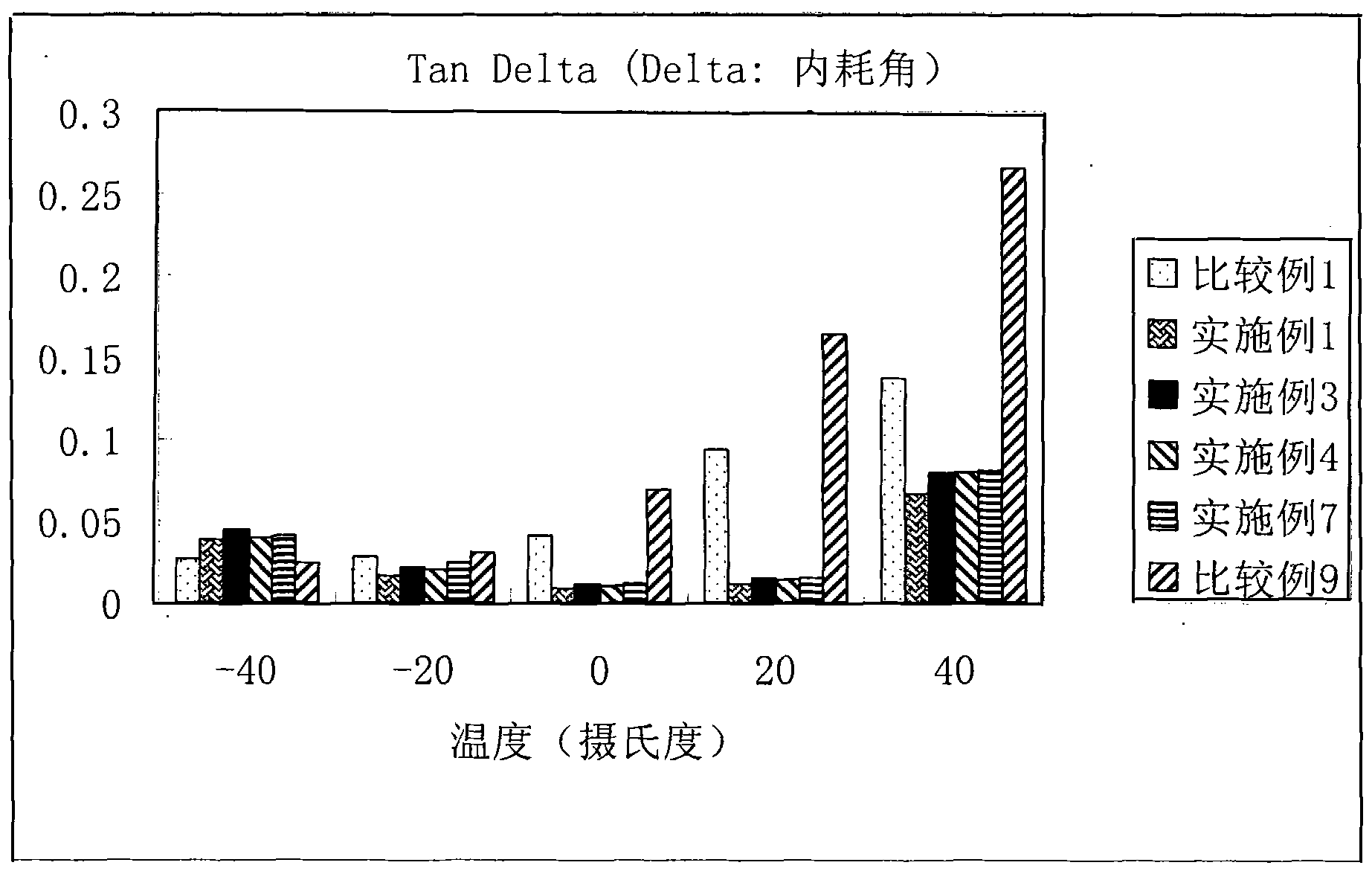

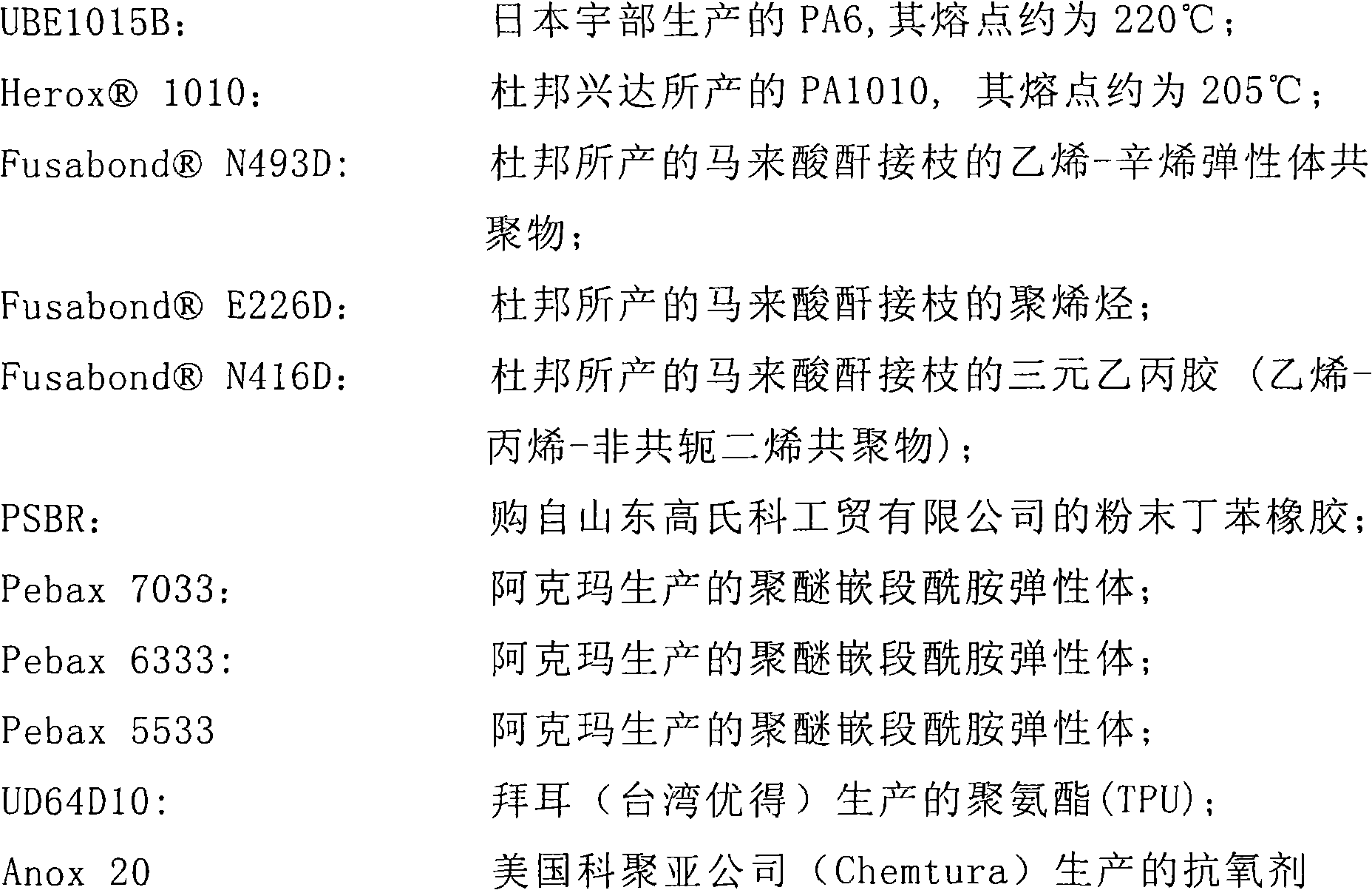

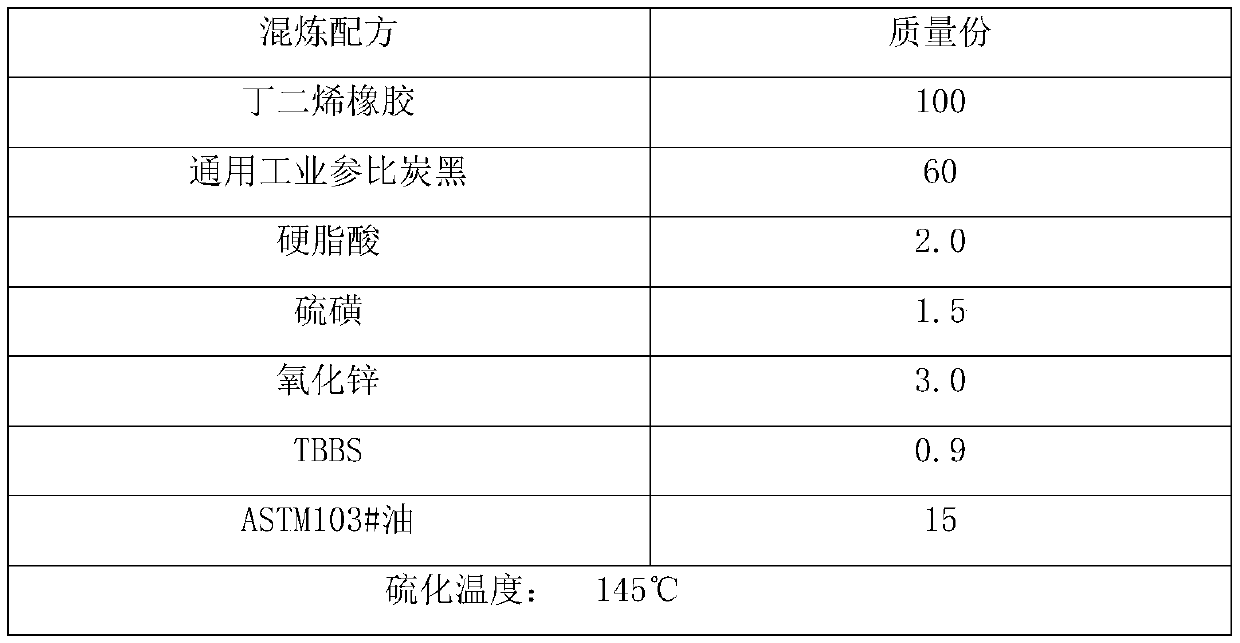

Polyamide alloy and application thereof

The invention discloses a polyamide alloy. The polyamide alloy comprises (a) 50 to 80 weight percent of at least one kind of aliphatic polyamide, and (b) 20 to 50 weight percent of ethylene copolymer mixture, wherein the ethylene copolymer mixture comprises at least two of the following components: (i) ethylene / olefin copolymer subjected to graft modification, (ii) ethylene propylene rubber subjected to graft modification, and (iii) styrene rubber; the ethylene / olefin copolymer to be subjected to graft modification before graft modification comprises 60 to 92 weight percent of comonomer unit from ethylene and 8 to 40 weight percent of one or more kinds of comonomer units from C4 to C10 alkene; and the ethylene propylene rubber to be subjected to graft modification before graft modification comprises 45 to 80 weight percent of comonomer unit from the ethylene, 20 to 55 weight percent of comonomer unit from propylene and 0 to 20 weight percent of one or more kinds of comonomer units from C5 to C10 non-conjugated chain alkadiene.

Owner:EI DU PONT DE NEMOURS & CO

A kind of preparation method of catalyst for preparing rare earth butadiene rubber

The invention relates to a preparation method for preparing a catalyst of rare earth butadiene rubber. The preparation method comprises the following steps: under nitrogen protection, successively adding a solution of a phosphoric acid rare earth compound, alkadiene and hydrogenated aluminum alkyl into a catalyst ageing bottle which is dried; ageing the mixture for 10-30min at 0-60 DEG C; then adding an organic chloride; ageing the mixture for 5-20min at 0-60 DEG C to from a homogeneous transparent solution; and then adding aluminum alkyl to age for 1-30min at 0-60 DEG C to prepare the catalyst of rare earth butadiene rubber. The catalyst is used for evaluating activity of butadiene polymerization. The monomer conversion rate is greater than or equal to 90%, the Mooney point of a product is 55-100, the number-average molecular weight is greater than or equal to 180 thousand and the molecular weight distribution is 1.3-2.5.

Owner:PETROCHINA CO LTD

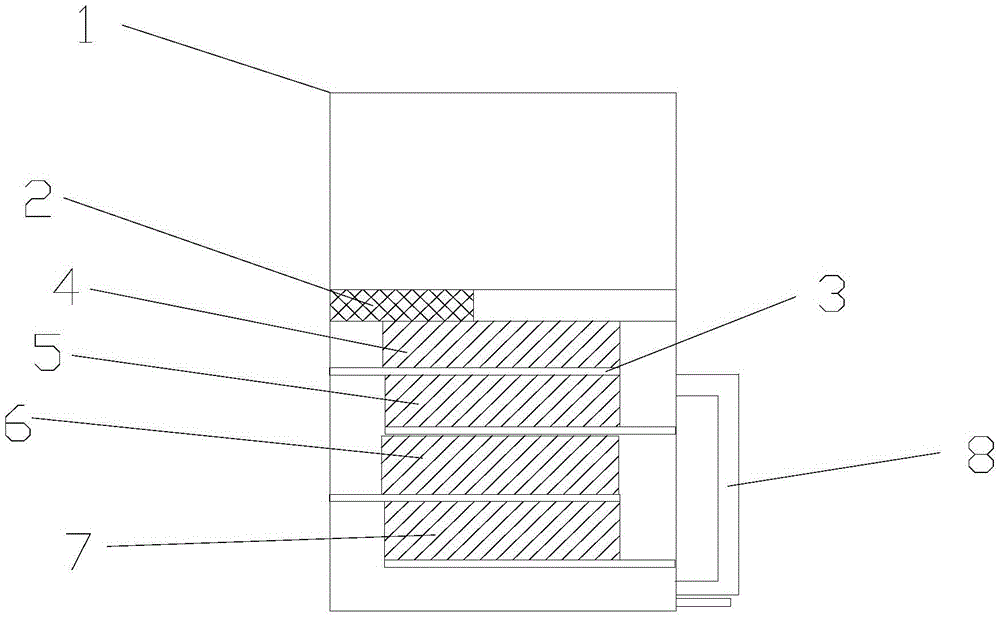

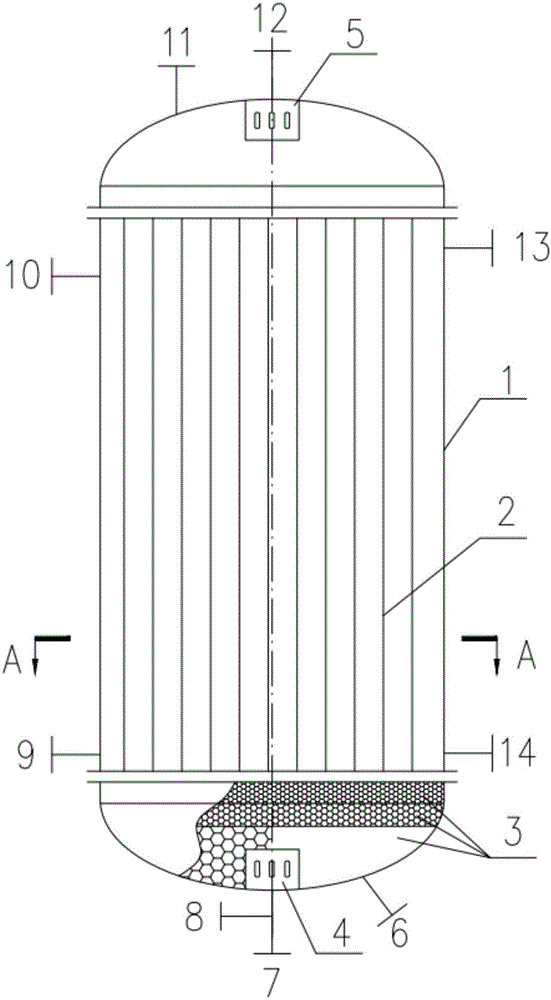

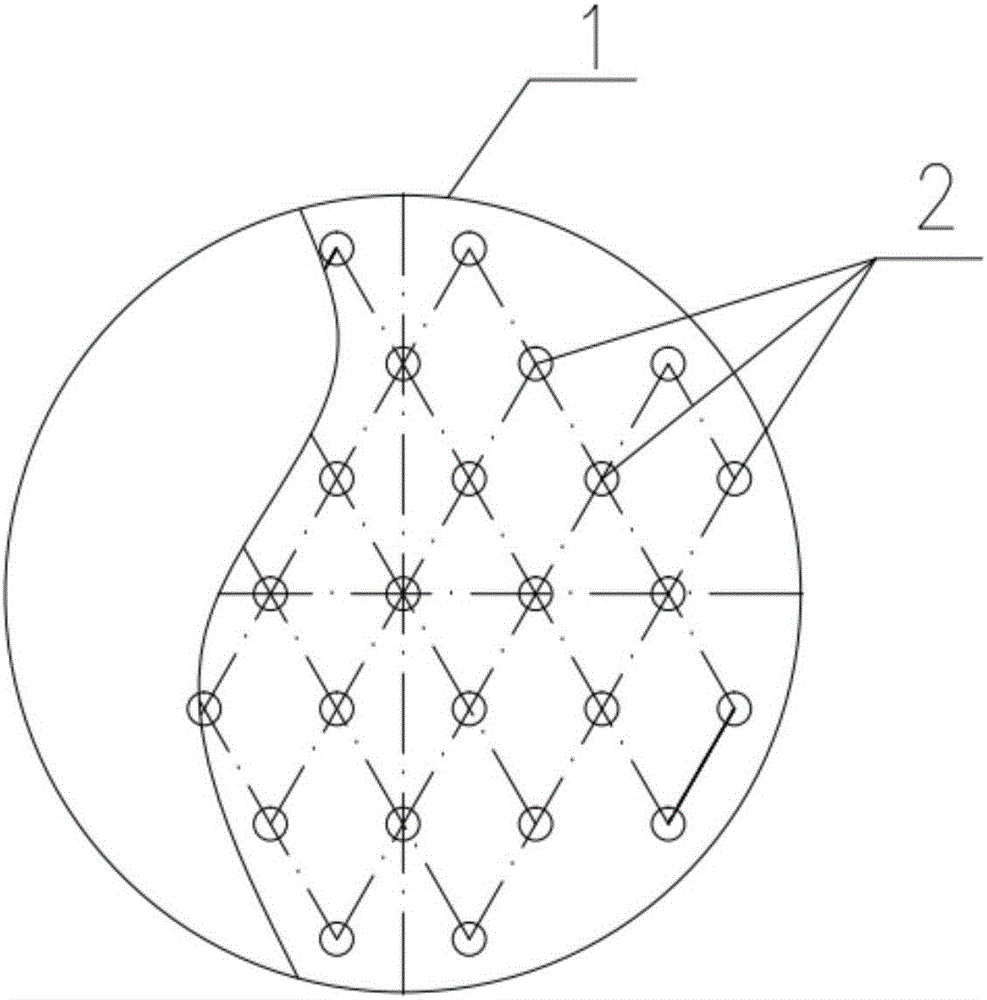

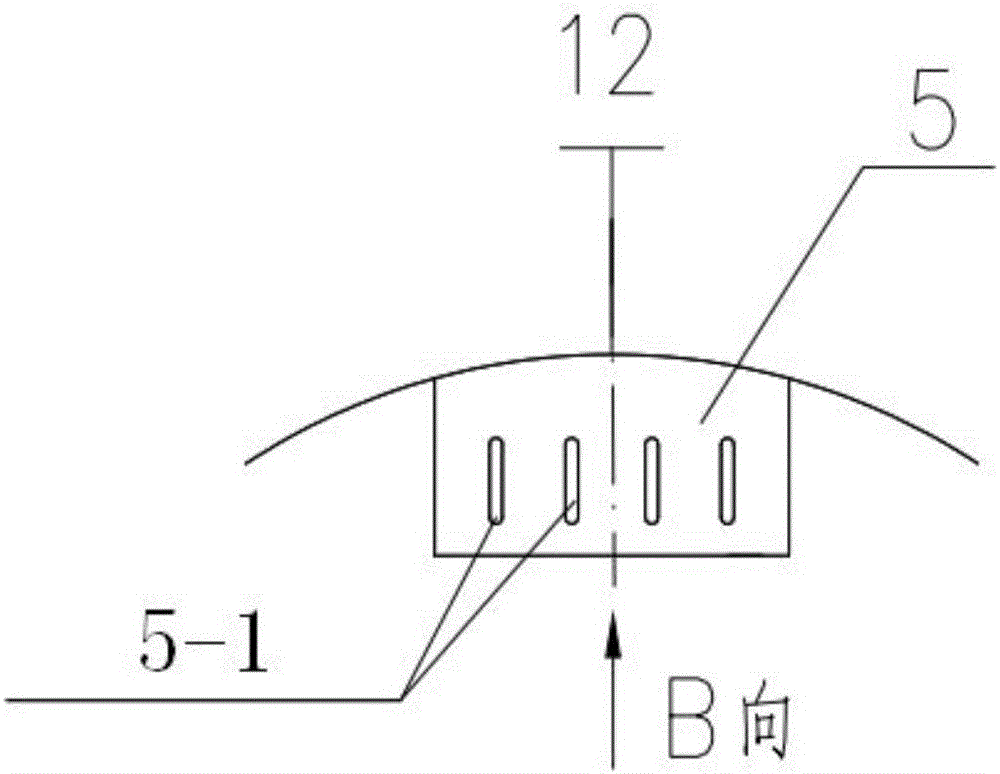

Tubular fixed-bed reactor for selective co-hydrogenation of mixed C4 containing high-concentration alkyne and alkadiene

InactiveCN106179132AAvoid rapid overheatingAvoid coking and other conditionsHydrocarbon by hydrogenationChemical/physical processesHigh concentrationFixed bed

The invention discloses a tubular fixed-bed reactor for selective co-hydrogenation of mixed C4 containing high-concentration alkyne and alkadiene. The reactor is the tubular fixed-bed reactor and comprises a casing, tubes, functional tube openings and internal pieces and the like; the tubes are filled with solid co-hydrogenation catalysts used for performing selective co-hydrogenation on mixed C4; the main functional tube openings and internal pieces of the reactor comprise multi-specification porcelain balls, an inlet distributor, an outlet collector, an unloading port, a feeding port, a circulating port, a water inlet, a water outlet, a safety valve port, a discharging port, an exhausting port and an emptying port. With the reactor, the technical problems of low conversion ratio of selective hydrogenation, large equipment size and coking of reactors due to rapid heating of traditional devices can be solved.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

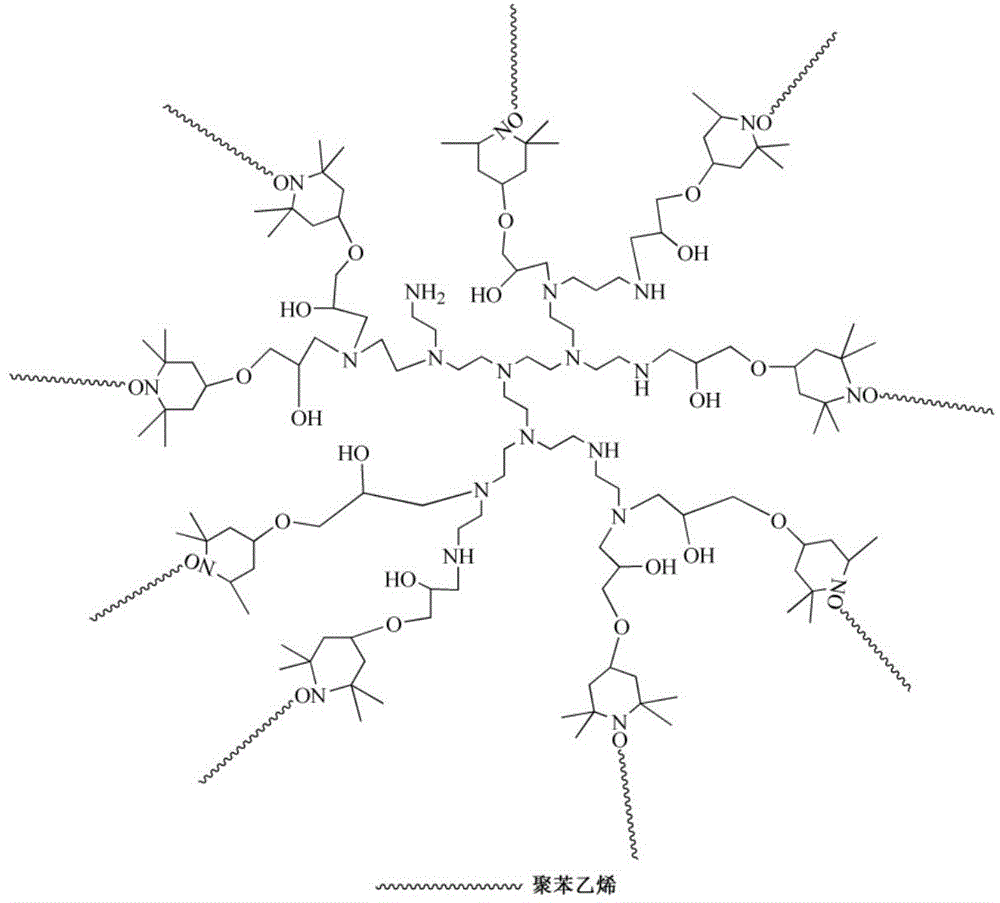

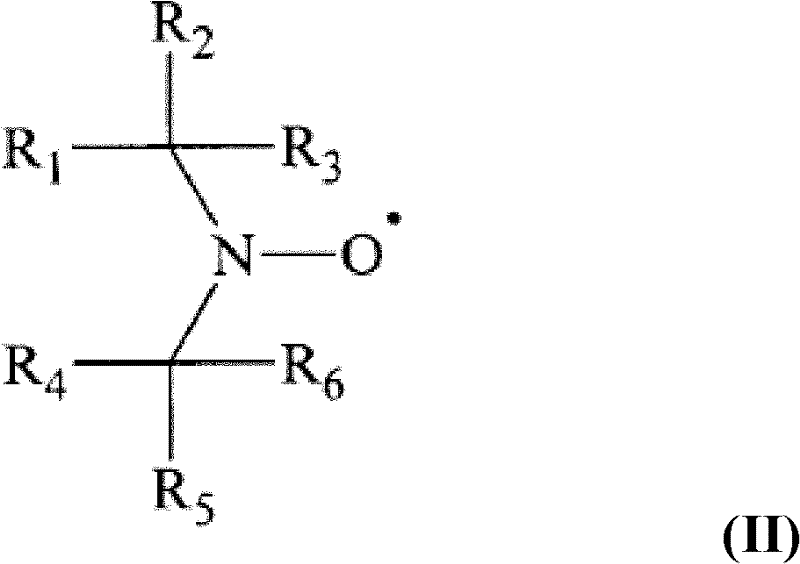

Process for the synthesis of functionalized poly(1,3-alkadienes) and use thereof in the preparation of high impact vinyl aromatic polymers

Process for the preparation of vinyl aromatic (co) polymers grafted on an elastomer in a controlled manner, comprising: dissolving an elastomer functionalized with bromoalkanes and nitroxy radicals, soluble in non-polar solvents, in a liquid phase consisting of a mixture of vinyl aromatic monomer (s) / polymerization solvent; feeding at least one radical initiator to the mixture, containing the functionalized elastomer in solution, and polymerizing the mixture thus obtained at a temperature higher than or equal to 1200C; recovering the vinyl aromatic (co) polymer obtained after devolatization;and recycling the solvent / monomer (s) mixture, coming from the devolatization, to step (a).

Owner:POLIMERI EUROPA SPA

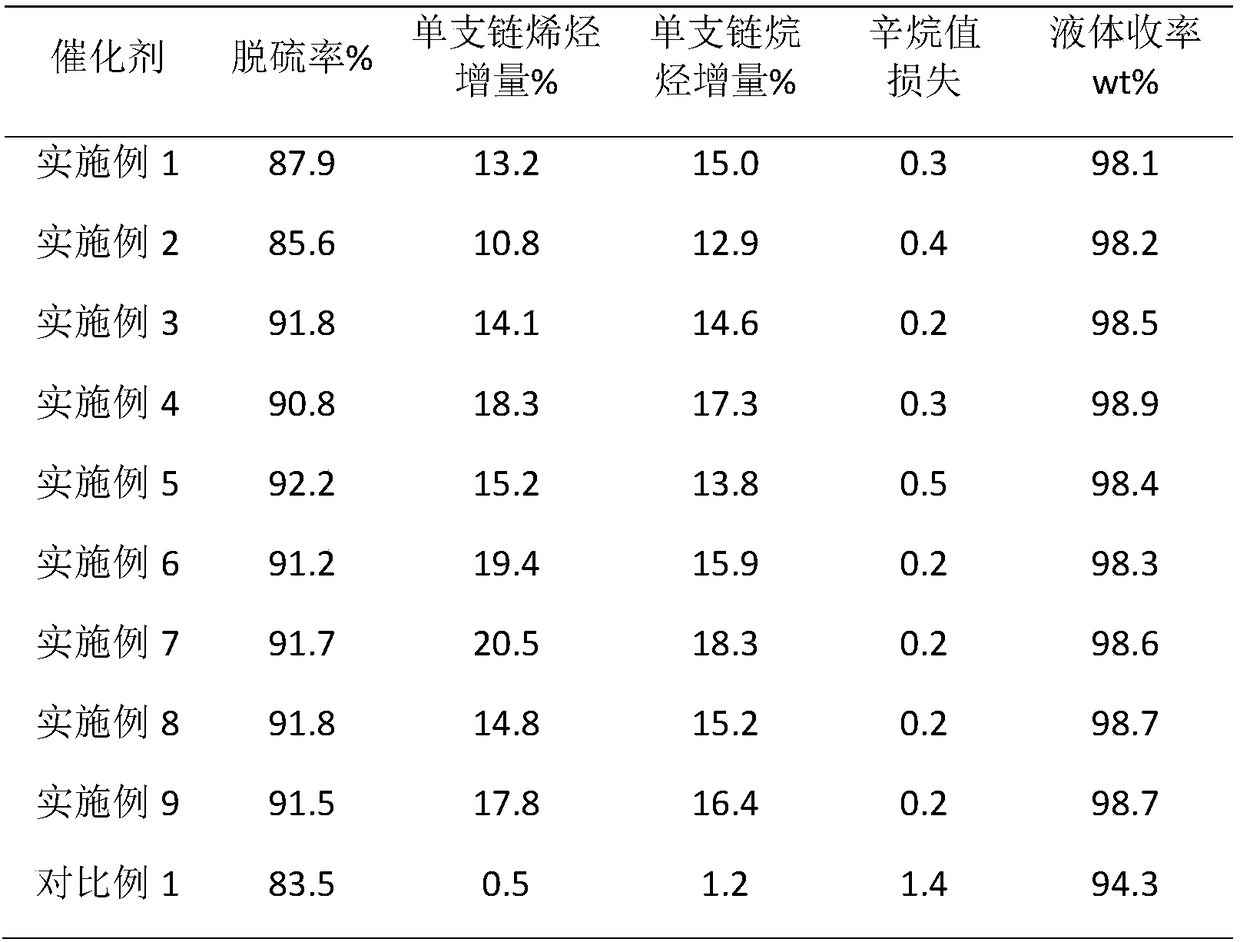

Method for reforming catalytic gasoline

ActiveCN109082297AHigh yieldReduction of re-cracking reactionsMolecular sieve catalystsHeterogenous catalyst chemical elementsAlkaneHydrodesulfurization

The invention relates to a method for reforming catalytic gasoline. The method includes: firstly, removing alkadiene, mercaptan and thioether from full-fraction FCC gasoline through a pre-hydrogenating reactor under the action of a pre-hydrogenation catalyst; then, subjecting a pre-hydrogenation product to selective hydrodesulfurization under the action of a hydrodesulfurization-isomeric catalystto obtain a clean gasoline product low in olefin, ultra-low in sulfur content and high in octane value, wherein straight-chain olefin isomerism is single-chain olefin or single-chain alkane.

Owner:FUZHOU UNIV

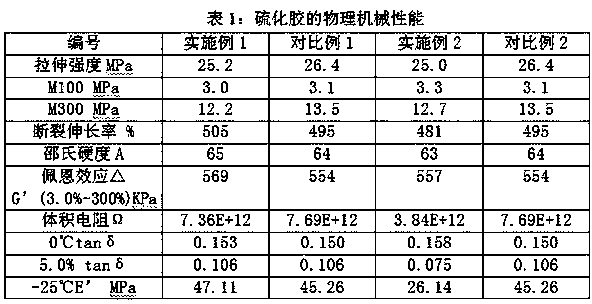

Tire tread rubber composition and preparation method thereof

InactiveCN109081961AIncrease low temperatureReduce rolling resistanceSpecial tyresRolling resistance optimizationElastomerRolling resistance

The invention relates to the technical field of rubber, in particular to a tire tread rubber composition. Based on 100 parts of alkadiene elastomers, the tire tread rubber composition further comprises, by weight, 10-90 parts of graphene oxide / silica, 0-10 parts of coupling agents, 0-5 parts of dispersing agents, 2-40 parts of carbon black, 1-7 parts of active agents, 1-8 parts of anti-aging agents, 1-4 parts of accelerators, 1-3 parts of sulfur and 0.1-1 part of anti-scorching agent. The tire tread rubber composition has the advantages that the graphene oxide is introduced in the form of graphene oxide / silica composites, so that the low temperature flexibility of tire treads is improved remarkably, in other words, the braking performance of tires on ice and snow is improved significantly;the thermogenesis of the rubber composition is reduced remarkably, in other words, the rolling resistance of the tires is reduced significantly; the tire tread rubber composition has improved antistatic property.

Owner:TRIANGLE TIRE

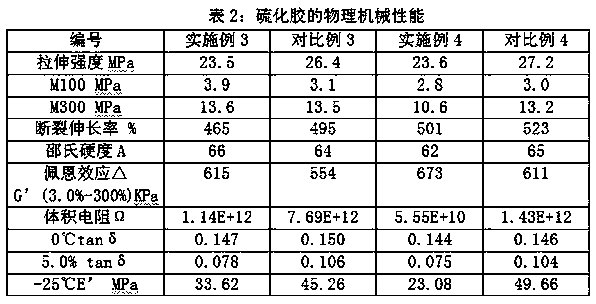

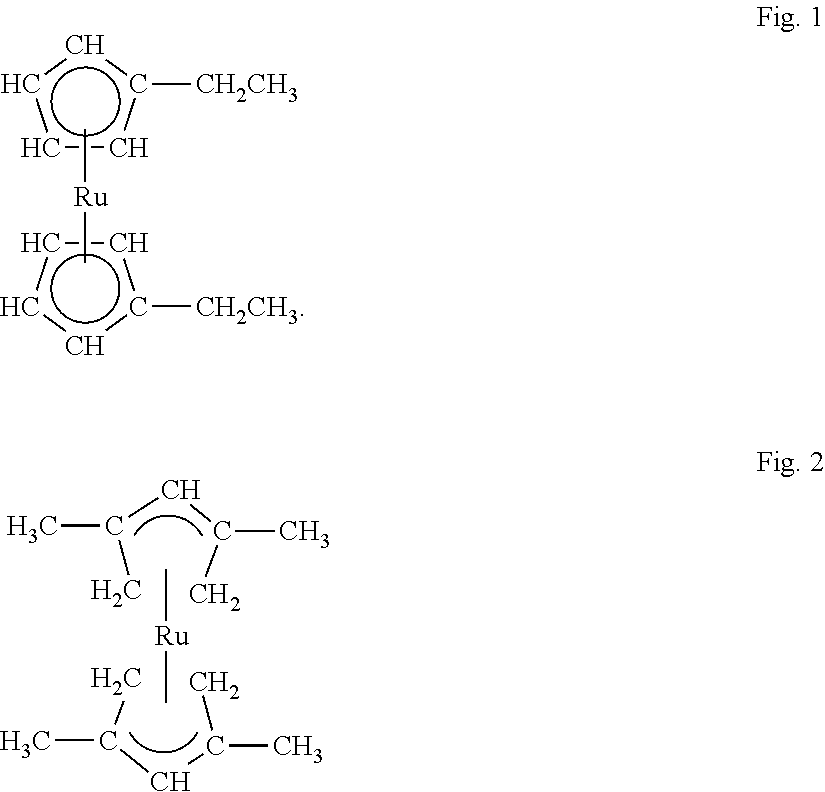

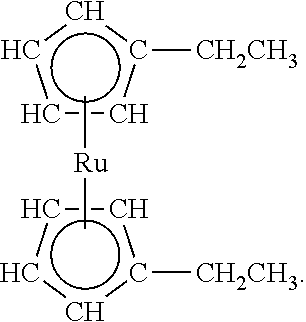

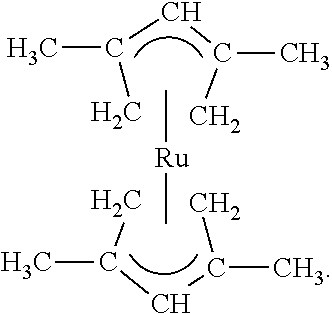

Process for the preparation of bis(pentadienyl)-complexes of iron group metals

A method for preparing organometallic complexes of the general formula (I):M(RPD)2 (I)in which M may be iron, ruthenium, or osmium, R is hydrogen or an alkyl group having about 1 to 4 carbon atoms, and PD is a cyclic or open chain dienyl system that is known to form a sandwich type complex is provided. The complexes having formula (I) have a metal purity of at least about 99.99%. The method involves reacting a M(III) trichloride hydrate with an HRPD compound and at least one reducing metal, such as aluminum, in an alcohol solvent.

Owner:HERAEUS PRECIOUS METALS GMBH & CO KG

Anti-fatigue tire compound and its preparation method

The invention discloses an anti-fatigue tire compound and its preparation method. The anti-fatigue tire compound is prepared from, by weight, 100 parts of alkadiene rubber, 30-50 parts of white carbon black, 0-10 parts of carbon black, 3-5 parts of active agent, 1-3 parts of anti-aging agent, 2-4 parts of bonding agent, and 6-10 parts of softening agent. According to the anti-fatigue tire compound, the rubber compound or final compound has very high anti-fatigue without adding the non-environmental-friendly antifatigue during the preparation process of the tire compound; through being detected by a carbon black dispersion tester, the dispersion grade of the prepared tire rubber can stably reach 7 and above; the fatigue test or the yield after thermal aging of the tire compound can be free from crack for 1.2 million times.

Owner:SICHUAN YUANXING RUBBER

Environment-friendly oil-resistant rubber sealing piece and preparation process thereof

InactiveCN106146923ALow expansion rate after oil immersionGood oil resistancePolymer scienceP-tert-octylphenol

The invention discloses an environment-friendly oil-resistant rubber sealing piece and a preparation process thereof. The sealing piece is prepared from the following raw materials: natural rubber, nitrile rubber, silicon rubber, butylene succinate, p-t-octylphenol formaldehyde resin, calcium stearate, L-lysine diisocyanate, crylic acid-acrylonitrile copolymer, ethylene-octylene-alkadiene terpolymer, spraying carbon black, copper ammonia fibers, ethylene glycol salicylate, tea-seed oil acid, tetrachlorophthalic acid dioctyl phthalate, tri-n-butyl citrate, an aluminate coupling agent, dicumyl peroxide, 2,4-DCBP, zinc dibutyl dithiocarbamate, zinc oxide, N-octyl N-octadecyl sulfo-amino MoDDC and butyl acetate. The rubber sealing piece provided by the invention is high in oil resistance and comprehensive mechanical property, green and environment-friendly, and is very suitable for being used as the rubber sealing piece widely applied to various fields.

Owner:潘明华

Modified polytrimethylene terephthalate resin and preparation method therefor

InactiveCN104861461AStrong impact resistanceGood anti-aging performanceGlycidyl methacrylateShock resistance

The invention discloses a modified polytrimethylene terephthalate resin and a preparation method therefor. The modified polytrimethylene terephthalate resin comprises the following ingredients, by weight, 75%-85% of PTT, 8%-12% of reinforcing agents, 4%-8% of flexibilizer, 1%-3% of antistatic agents, 0.5%-2% of light stabilizing agents, 0.1%-0.5% of anti-oxidants and 0.1%-1% of lubricants. The flexibilizer is one of maleic anhydride-graft-ethylene-octene copolymer, maleic anhydride-graft-ethylene-propylene-alkadiene copolymer, maleic anhydride-graft-phenylethylene-ethylene-butadiene-phenylethylene copolymer, glycidyl methacrylate-graft-phenylethylene-ethylene-butadiene-phenylethylene copolymer, glycidyl methacrylate-graft-phenylethylene-butadiene-phenylethylene segmented copolymer. The beneficial effects are that the modified polytrimethylene terephthalate resin has advantages of excellent shock resistance, high intensity, high ageing resistance, good processability, beautiful molding and the like.

Owner:QINGDAO XINZHAN PLASTIC

Method for preparing white carbon black hybridized material prepared by modification with end chlorosilane polymer

ActiveCN102229759AEffectively control the degree of chlorosilylationGood dispersionPigment treatment with macromolecular organic compoundsPolymer modifiedPolymer science

The invention discloses a method for preparing a white carbon black hybridized material prepared by modification with an end chlorosilane polymer, belonging to the field of synthesis of hybridized materials. The method comprises the following steps of: (1) adding chlorosilane in an anionic reactive polymer, reacting at 30-60 DEG C for 10-40 minutes to obtain the end chlorosilane polymer, wherein the reactive polymer includes styrene polymers, polymers of derivatives of styrene, alkadiene polymers and mixtures of two or more than two of the styrene polymers, the polymers of derivatives of styrene and the alkadiene polymers; (2) mixing white carbon black and the end chlorosilane polymer uniformly, reacting at 25-100 DEG C for 1-48 hours, removing a solvent to obtain an organic / inorganic hybridized material of the end chlorosilane polymer bonded with white carbon black, wherein the mass ratio of the end chlorosilane polymer to the white carbon black is 20:1-1:10. According to the invention, the aggregation of the white carbon black is reduced, affinity between the white carbon black and the polymer is improved, phase separation is reduced obviously, and the prepared material has excellent comprehensive performance. The method is easy to operate, the grafting efficiency is between 50% and 90%, and the prepared white carbon black as an organic hybridized material has the grafting grade being about 0.025:1-9:1.

Owner:BEIJING UNIV OF CHEM TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com