Polyamide alloy and application thereof

A polyamide and aliphatic polyamide technology, applied in the field of polyamide alloys, can solve the problems of high manufacturing cost, difficult wear resistance and low temperature flexibility, expensive polymerization equipment required for manufacturing, etc., and achieve simple preparation method and low cost , high tear resistance and energy recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076]2. Sample preparation: Select a suitable mold according to the requirements of the test, and the extruded particles are plasticized by an injection molding machine and molded at a processing temperature of 240-260°C. The formed samples are subjected to various tests according to the actual situation.

[0077] Compared with existing polyether block amide polymer resins, the polyamide alloy described herein does not require expensive special polymerization equipment, thereby greatly reducing its manufacturing cost.

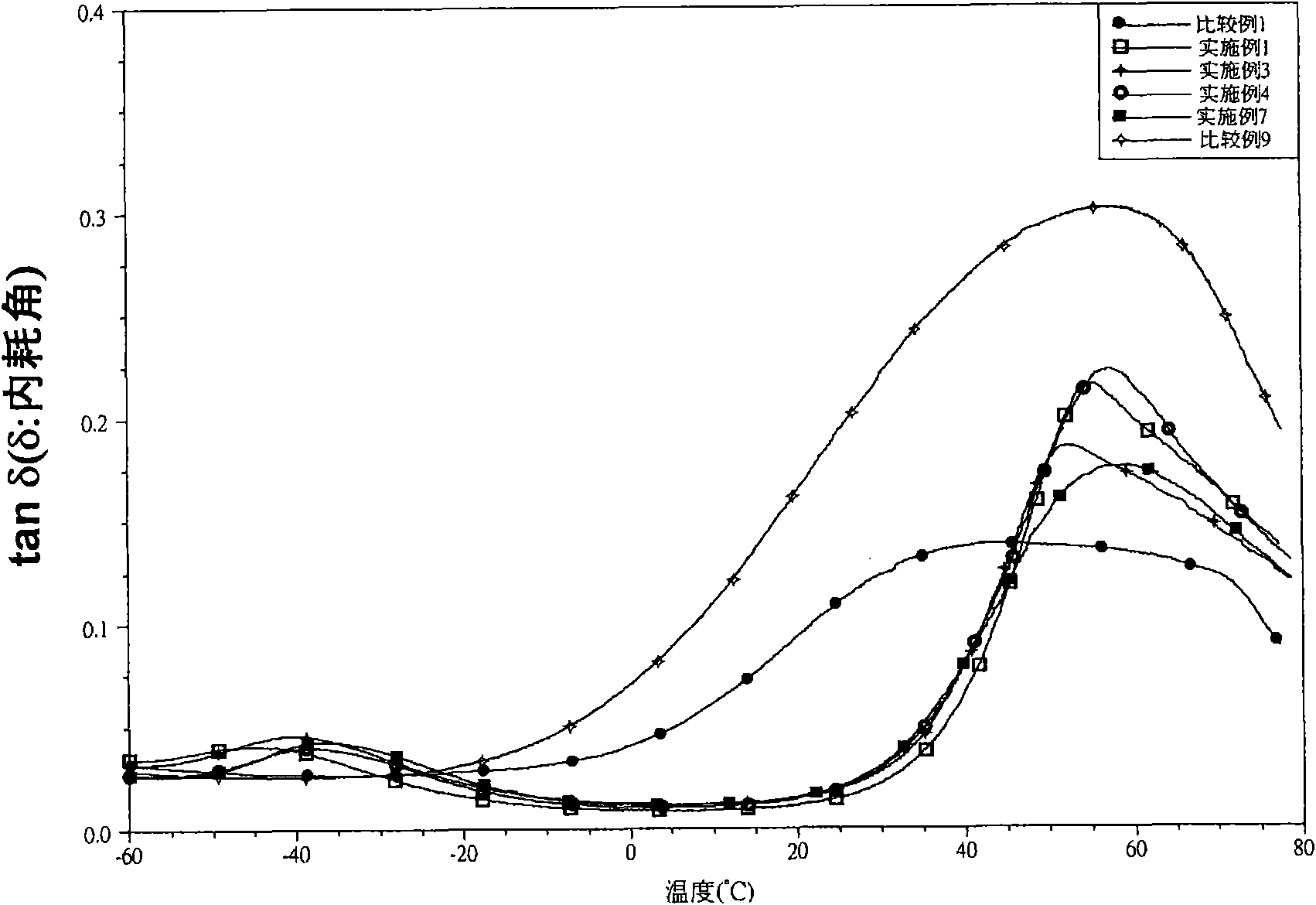

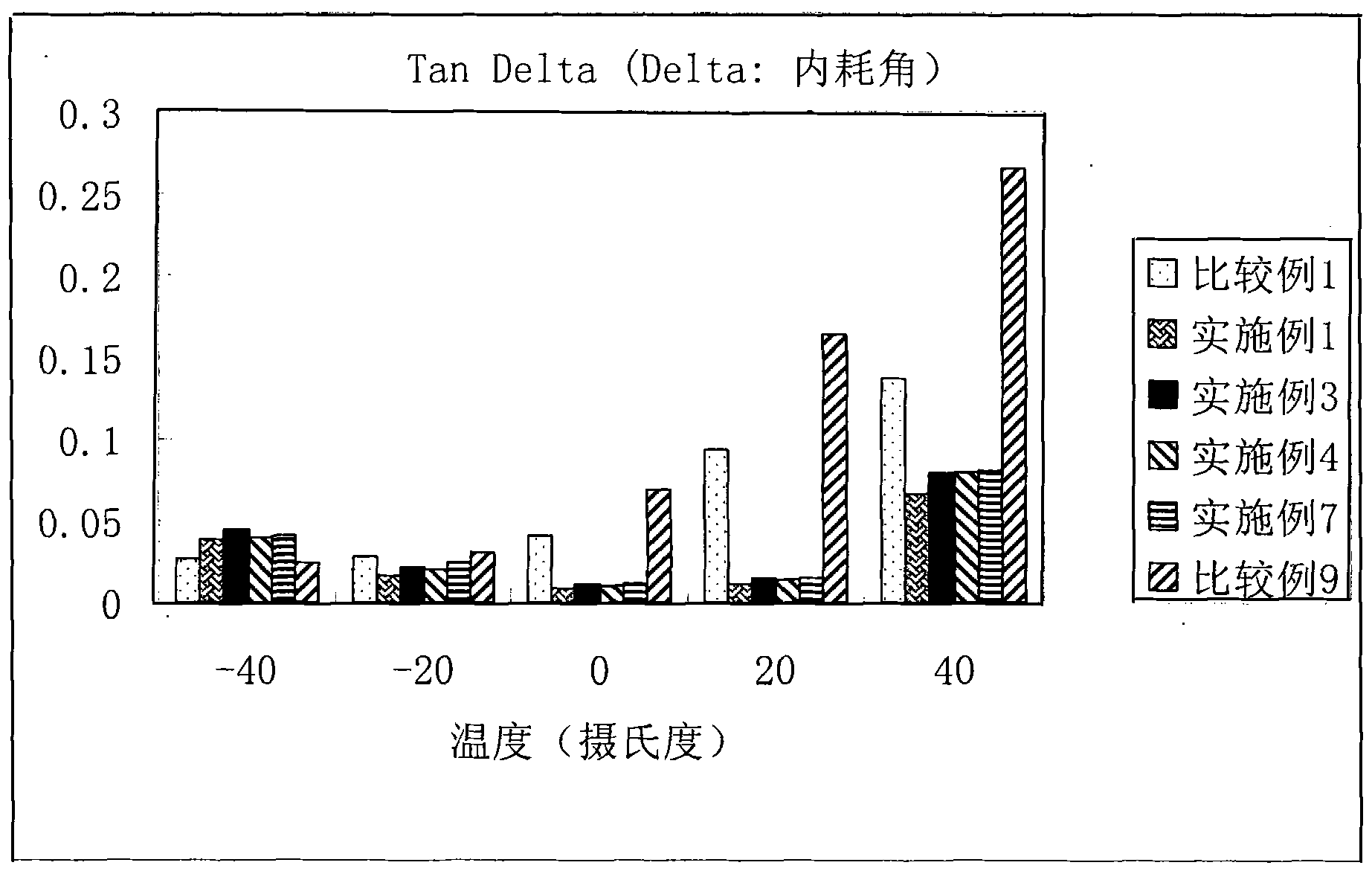

[0078] In addition, the polyamide alloy described herein has similar properties to existing polyether block amide polymer resins (hereinafter referred to as existing resins): its Shore D hardness (ASTM D 2240) is 64-68D ( Existing resin is 60-66D), specific gravity (ASTM D 297) is 0.99-1.01 (existing resin is 0.98-1.02), tensile strength (ASTM D 412) is 333-373 (existing resin is 380kg / cm 2 ), elongation at breaking point (ASTM D 412) is 159-190% (300% for ...

Embodiment

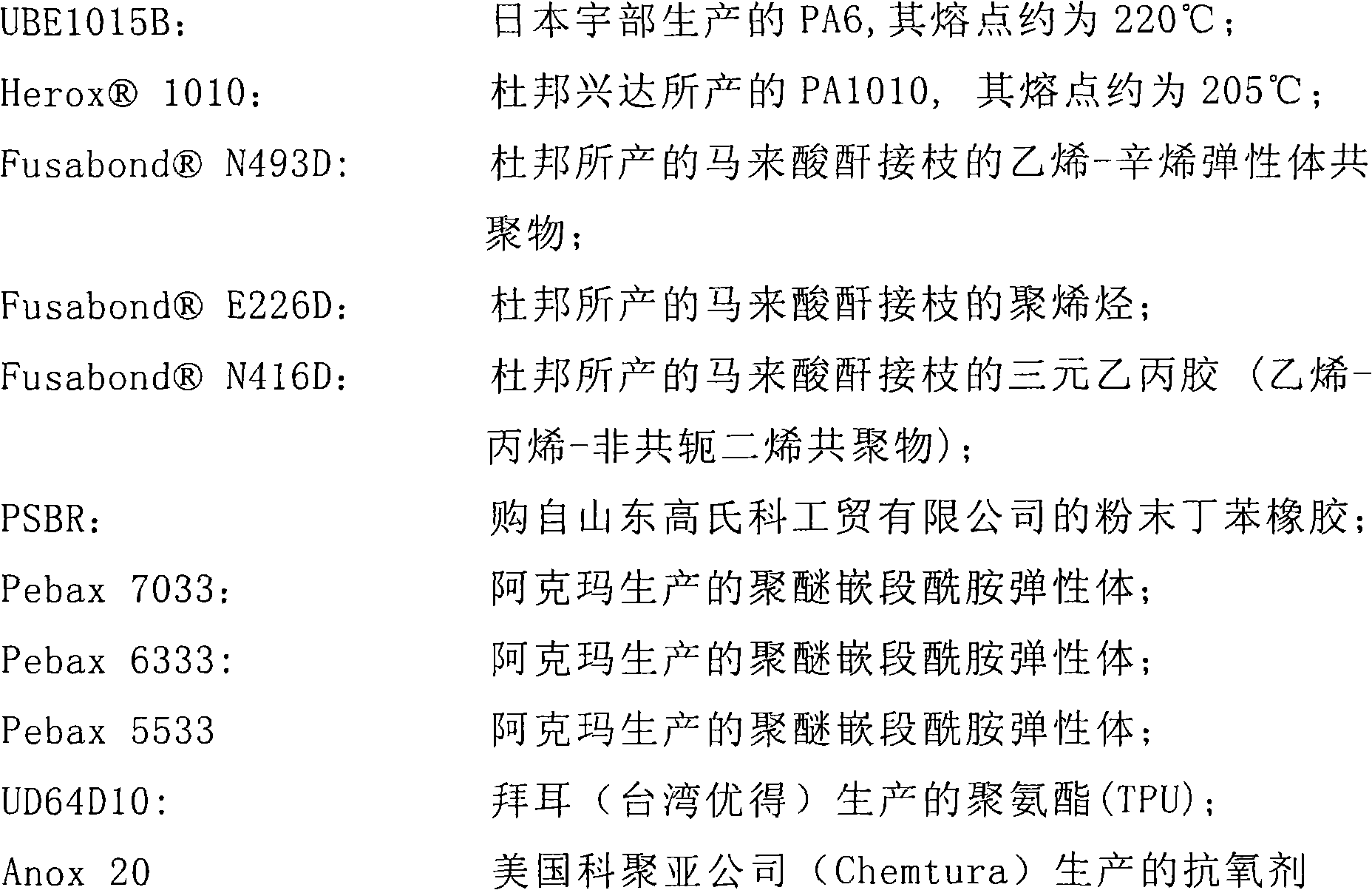

[0081] The following products were used as starting materials in the following examples:

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com