Method for reforming catalytic gasoline

A technology for catalytic cracking gasoline and upgrading, which is applied in chemical instruments and methods, catalyst activation/preparation, chemical elements of heterogeneous catalysts, etc. The effect of improving octane number and high gasoline yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

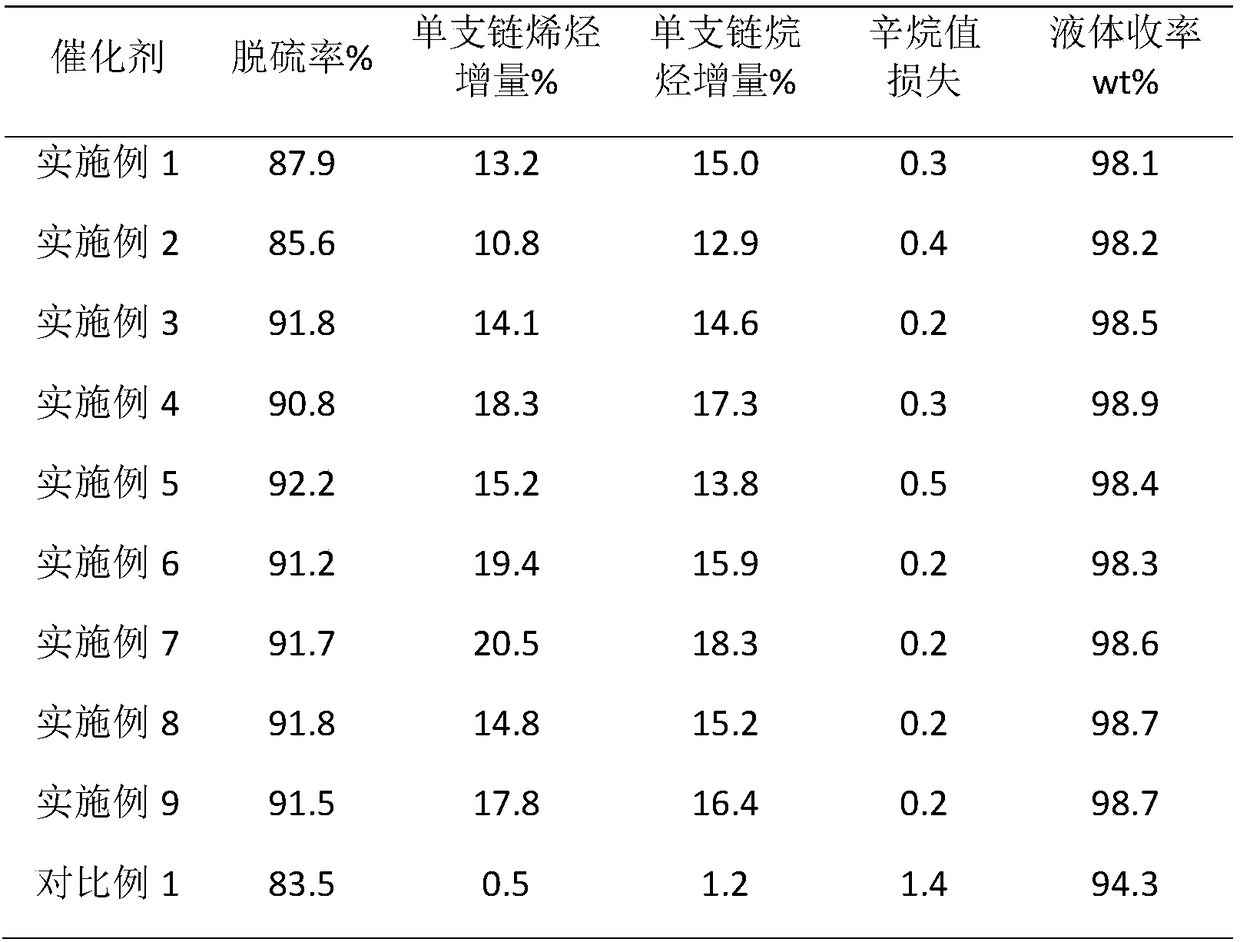

Examples

Embodiment 1

[0032] 1. Preparation of tungsten-doped lanthanum ferrite with micro-mesoporous

[0033] Under stirring conditions, 2.2mol La(NO 3 ) 3 Dissolve in 100mL water, add citric acid and stir to dissolve; then add 4.2mol Fe(NO 3 ) 3 , and then add 160g of sodium polyacrylate, then add an aqueous solution containing 10g of ammonium metatungstate, continue stirring for 30min, and obtain micro-mesoporous tungsten-doped lanthanum ferrite through drying, roasting and grinding.

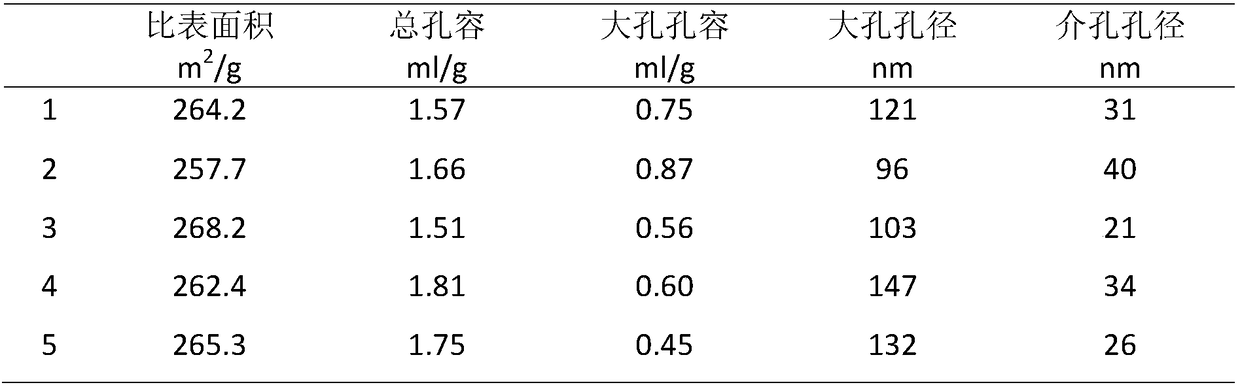

[0034] 2. Preparation of alumina carrier

[0035] Add citric acid to 2.2g of micro-mesoporous tungsten-doped lanthanum ferrite for later use, add 300g of pseudo-boehmite powder and 20.0g of scallop powder into the kneader, mix well, then add nitric acid and 8g of sodium polyacrylate, Knead evenly, then add micro-mesoporous tungsten-doped lanthanum ferrite, mix evenly, and knead-extrude into a clover shape. Dry at 120° C. for 8 hours, and calcined at 700° C. for 4 hours to obtain an alumina carrier 1 containin...

Embodiment 2

[0039] 1. Preparation of tungsten-doped lanthanum ferrite

[0040] Under stirring conditions, 2.2mol La(NO 3 ) 3 Dissolve in 100mL water, add citric acid and stir to dissolve; then add 4.2mol Fe(NO 3 ) 3 , then add an aqueous solution containing 10g of ammonium metatungstate, continue to stir for 30 minutes, and obtain tungsten-doped lanthanum ferrite through drying, roasting and grinding.

[0041] 2. Preparation of alumina carrier

[0042] Add citric acid to 2.2g of tungsten-doped lanthanum ferrite, add 300g of pseudoboehmite powder and 20.0g of scallop powder into the kneader, and mix well, then add nitric acid and 8g of sodium polyacrylate, knead evenly, and then Add tungsten-doped lanthanum ferrite, mix well, and knead-extrude into a clover shape. Dry at 120° C. for 8 hours, and calcined at 700° C. for 4 hours to obtain alumina carrier 2 containing tungsten-doped lanthanum ferrite. The carrier pore structure is shown in Table 1.

[0043] 3. Preparation of catalyst ...

Embodiment 3

[0046] The preparation of the carrier is the same as in Example 1, except that the micro-mesoporous tungsten-doped lanthanum ferrite accounts for 6 wt% of the carrier. The preparation of the catalyst was the same as in Example 1, using activated montmorillonite as the aluminum source. The difference is that phosphomolybdenum acid is added, and the main composition of the catalyst 3 is: 88.8wt% alumina carrier of micro-mesoporous tungsten-doped lanthanum ferrite, and 11.2wt% phosphomolybdenum oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com