Peeling-off mechanism of corn harvesting machine

A corn harvester and cleaning mechanism technology, which is applied to harvesters, agricultural machinery and tools, and threshing equipment, can solve the problems of small grasping force, large longitudinal movement resistance, and easy slipping of corn ears, so as to reduce slipping and increase High gripping force, favorable peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

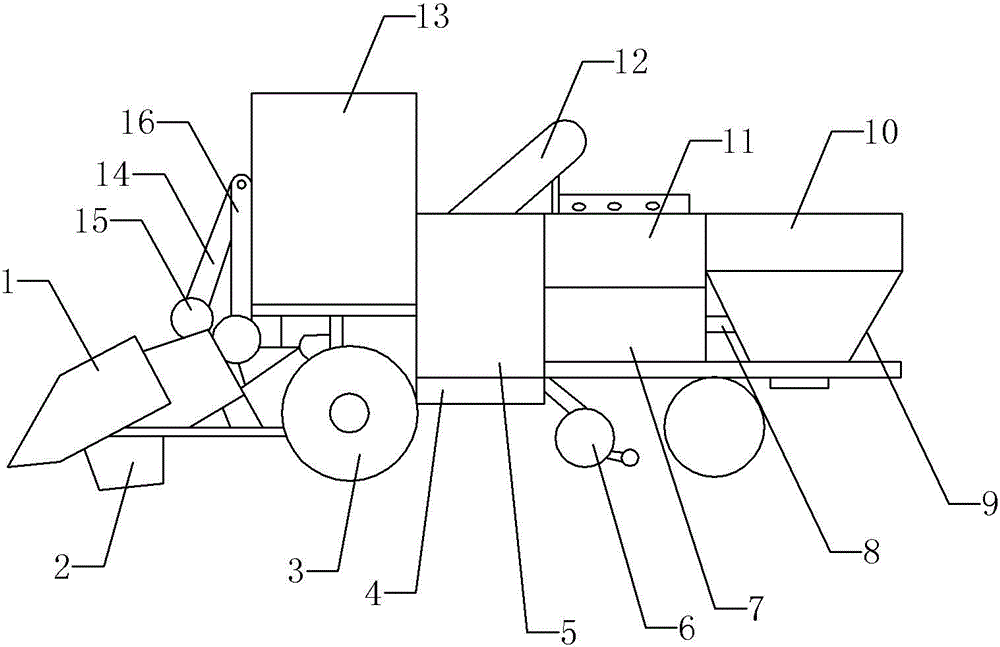

[0016] Instructions attached figure 1 The reference signs in include: cutting platform 1, cutting device 2, traveling wheel 3, traveling chassis 4, power mechanism 5, field returning machine 6, cleaning device 7, conveying path 8, hopper 9, beard ear separation device 10, Peeling device 11, lifting device 12, cab 13, second support arm 14, climbing wheel 15, first support arm 16.

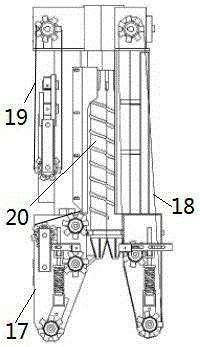

[0017] as attached figure 1 In the peeling mechanism of the corn harvester shown, the power mechanism is arranged on the upper part of the walking chassis and is located in the middle of the whole machine, and the driver's cab is arranged on the walking chassis and is located in front of the power mechanism. The traveling wheels include front traveling wheels and rear traveling wheels, and the front traveling wheels and the rear traveling wheels are respectively located on both sides of the traveling chassis. The front of the walking chassis is equipped with a header device and a cutting device lo...

Embodiment 2

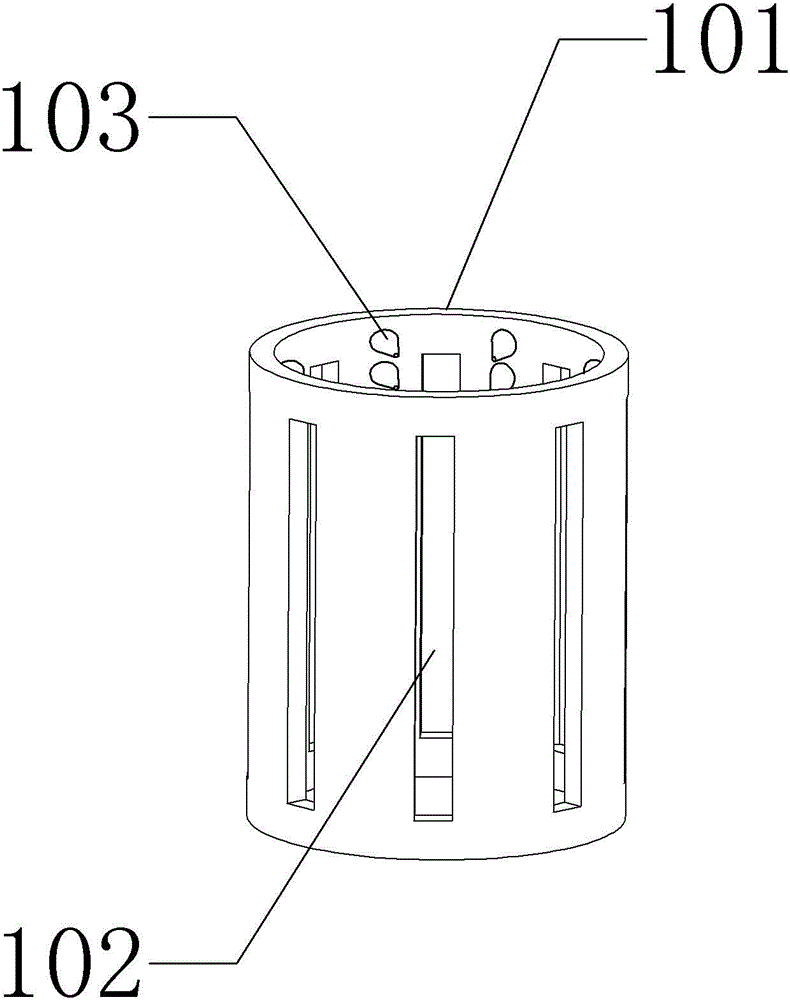

[0038] The difference between the present embodiment and the first embodiment is only the ear separating device, and other structures are basically the same as in the first embodiment. The ear separating device of the present embodiment includes a separation chamber, and the bottom of the separation chamber is connected with the upper opening of the ear box, and the separation There is a horizontal rotatable three-jaw elastic jaw 101 in the room. The three-jaw elastic jaw has three circumferentially evenly distributed jaws 102. The three-jaw elastic jaw is driven by the sprocket chain in the second transmission. The three-jaw elastic The inner diameter of the jaws is equivalent to the small head diameter of a single ear of corn.

Embodiment 3

[0040] The present embodiment differs from Embodiment 1 only in the beard and fringe separation device, and other structures are basically the same as in Embodiment 1. The beard and fringe separation device includes an inclined cylindrical conveying separation path 101, and the conveying and separation path 101 is driven by the second road. The sprocket chain in the chain drives the ratchet pawl mechanism, and the ratchet pawl mechanism vibrates back and forth during the conveying process. The front end of the conveying separation path 101 is connected with the upper opening of the ear box, and the side wall of the conveying separation path is provided with a plurality of axial A strip-shaped through hole 102, a strip-shaped guide hole is opened on the upper side wall of the conveying separation path, and a pendulum brush 103 that can reciprocate axially along the conveying separation path is arranged in the guide hole. The bristles have blades.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com