Plant protein raw material processing device and processing method thereof

The technology of a vegetable protein and a processing method is applied to a vegetable protein raw material processing device and its processing field, which can solve problems such as inconvenient operation, and achieve the effects of inhibiting enzymatic oxidation reaction, increasing protein extraction rate, and improving flavor and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

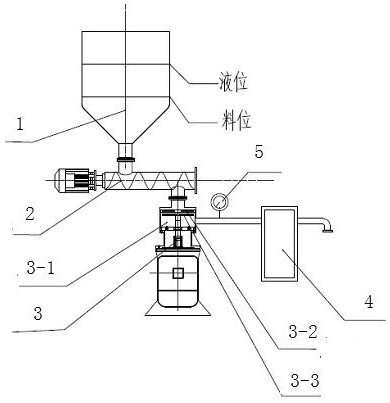

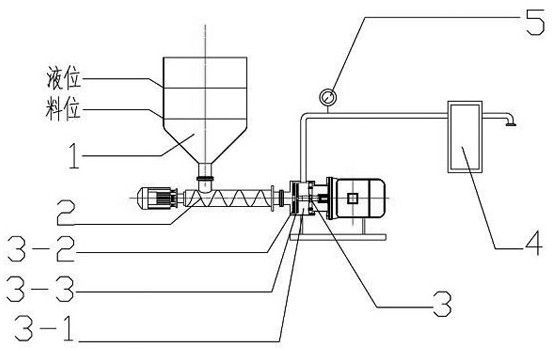

[0026] Example 1 A plant protein raw material processing device

[0027] It includes a pre-tank 1, a solid-phase material quantitative feeder 2, a refiner 3, and a grinding flow controller 4; the bottom outlet of the pre-tank 1 is connected to the inlet of the solid-phase material quantitative feeder 2. The outlet of phase material quantitative feeder 2 is connected with the inlet of refiner 3 , and the outlet of refiner 3 is connected with grinding flow controller 4 .

[0028] Sealing measures are taken at the joints of the interfaces to prevent leakage. A grinding chamber 3-1 is arranged in the refiner 3, and a fixed grinding disk 3-2 and a moving grinding disk 3-3 are also arranged in the grinding chamber 3-1. A pressure gauge or a pressure sensor 5 is also provided between the paste flow controller 4 and the outlet of the refiner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com