Individualized bone cutting guide plate suite and design method thereof

A design method and osteotomy technology, applied in the direction of surgical saws, etc., can solve the problems of uneven development of femoral condyles, bone defects, lower osteotomy accuracy, troubles, etc., and achieve convenient positioning and compression, reduce surgical steps, and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Typical examples embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different examples without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not intended to limit the present invention. .

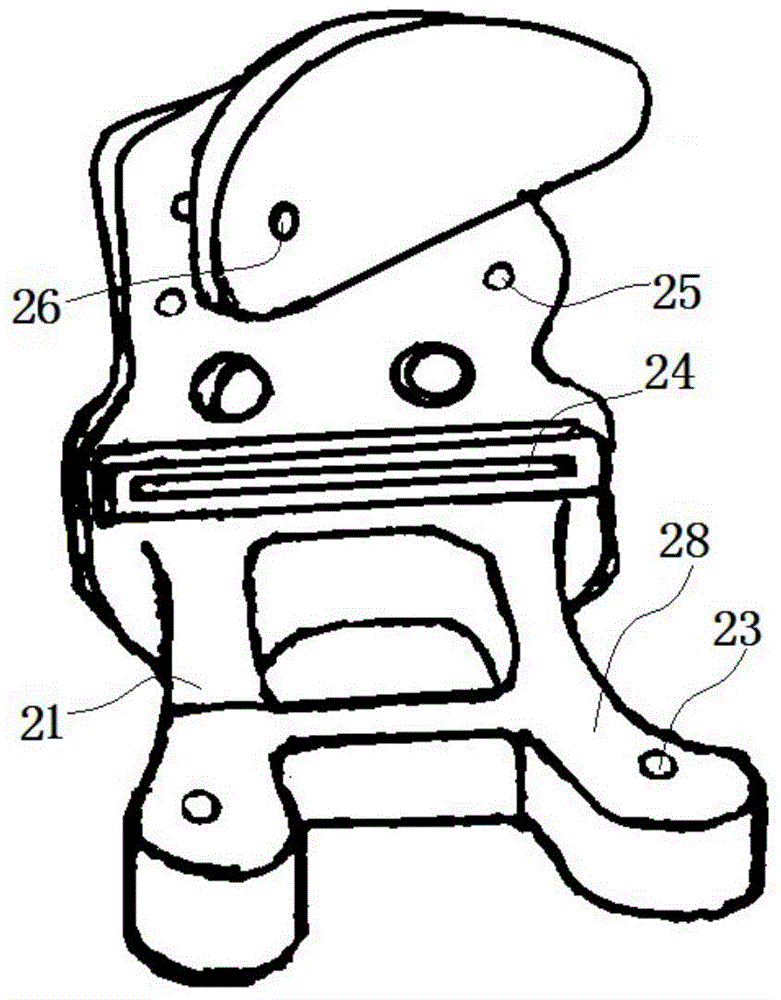

[0059] An individualized osteotomy guide set, mainly composed of an individualized knee joint proximal tibial osteotomy guide plate, an individualized knee joint distal femur osteotomy guide plate, and an individualized femur multifaceted osteotomy set.

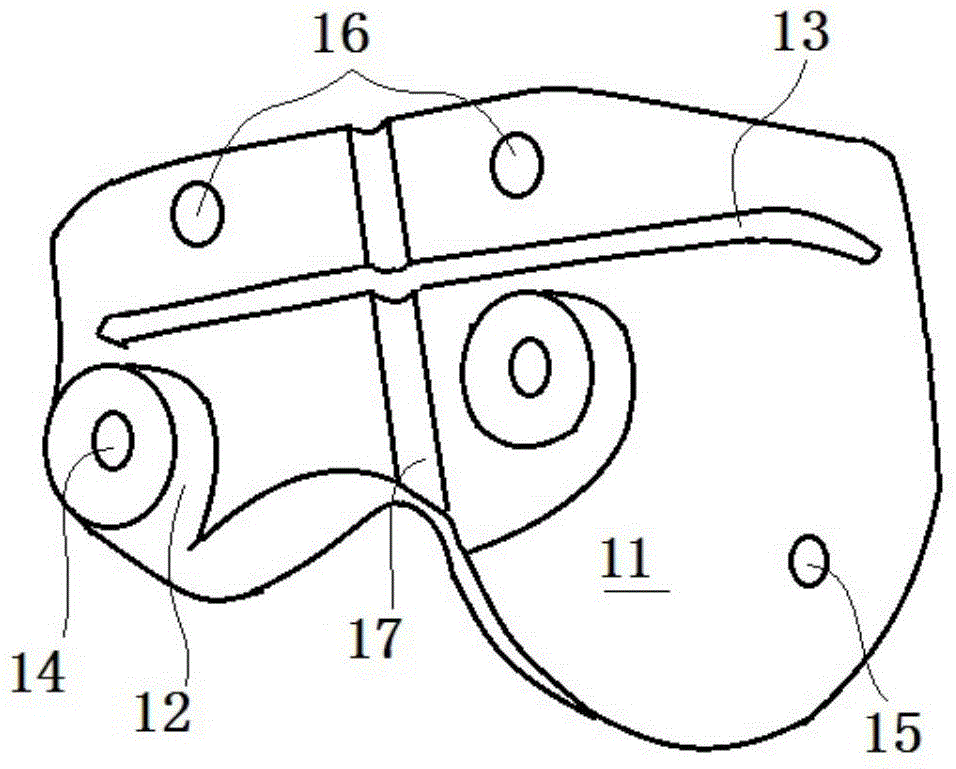

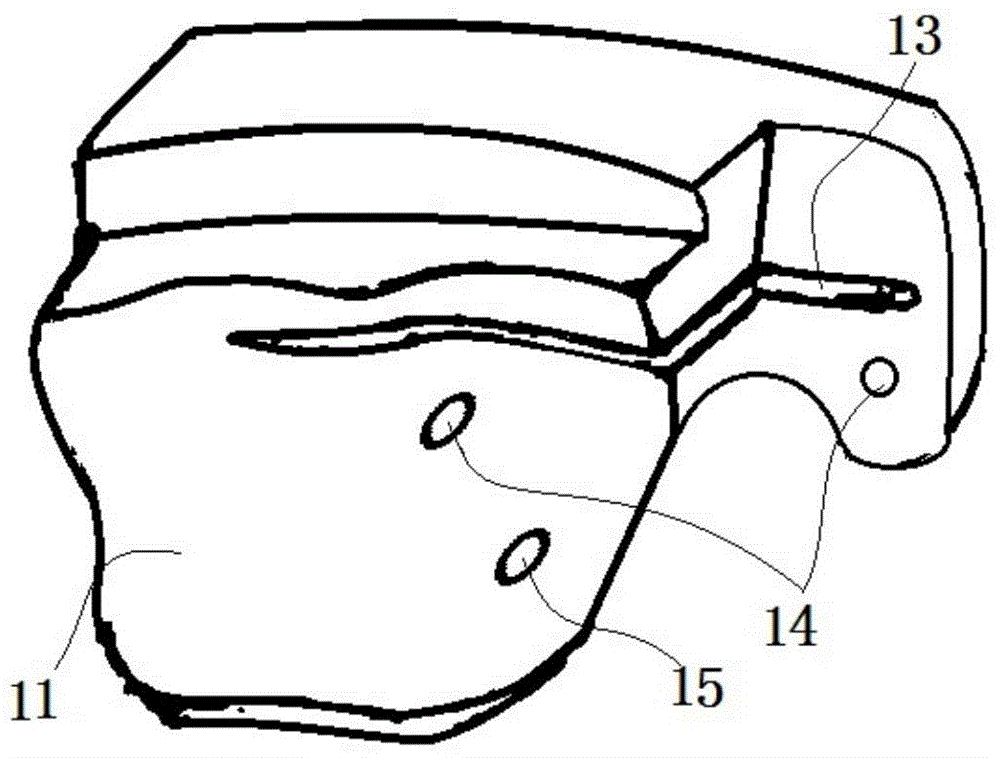

[0060] Such as figure 1 and figure 2 As shown, the proximal tibial osteotomy guide includes a proximal tibial osteotomy guide body 11 , a positioning post 12 , and a tibial osteotomy groove 13 . Among them, the shape of the medial surface of the proximal tibia osteotomy guide plate body 11 is the negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com