Self-healing type bituminous concrete and preparation method thereof

A kind of asphalt concrete, self-healing technology, applied in the field of self-healing asphalt concrete and its preparation, can solve the problems that cannot fundamentally solve road diseases, consume a lot of manpower, material resources, financial resources, etc., and achieve saving maintenance and repair costs, economic and social benefits Good, evenly graded results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, preparation of self-healing asphalt concrete and its performance test:

[0044] One, the preparation method of self-healing asphalt concrete, specifically comprises the following steps:

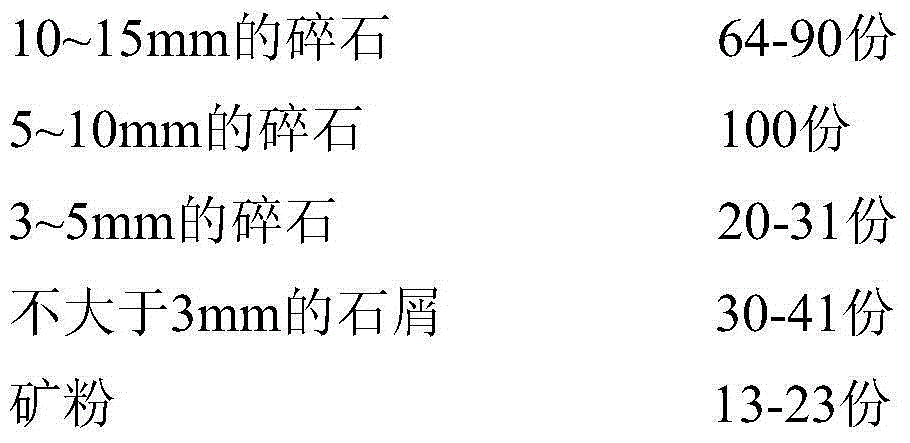

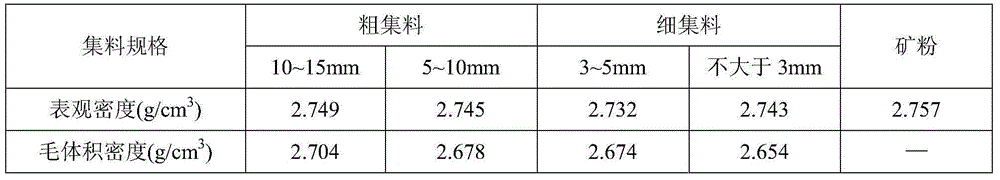

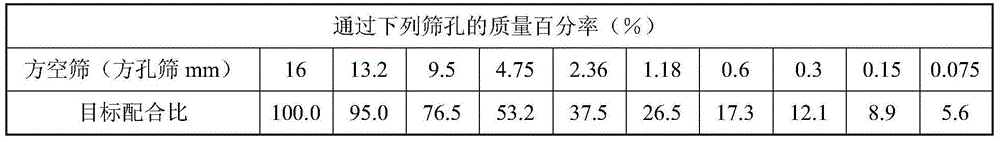

[0045] 1) Mix 76.9 parts of crushed stones of 10-15mm, 100 parts of crushed stones of 5-10mm, 25.6 parts of crushed stones of 3-5mm, 35.6 parts of stone chips not larger than 3mm and 18.2 parts of mineral powder to obtain mineral materials , the gradation composition of the mineral aggregate is shown in the following table 4, then, prepare 100 parts of mineral aggregate, 5.6 parts of SBS modified asphalt and 2.2 parts of steel wool by mass parts respectively,

[0046] Table 4. Gradation composition

[0047]

[0048] 2) Put 100 parts of ore in a pan and preheat to 180°C in an oven; then preheat SBS modified asphalt to 150°C to make it liquid; preheat steel wool to 120°C ℃;

[0049] 3) Pour the mineral material into the mixing pot, then mix the steel wool into the min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com