Turbine Driven Debris Bed Remover

A technology for removing devices and cuttings beds, which is applied in wellbore/well components, earthwork drilling, and flushing wellbore, etc. It can solve the problems of prone to accidents and high cost of cuttings removal, so as to ensure mechanical strength and improve cuttings Removal efficiency, the effect of preventing the formation of cuttings beds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described further below:

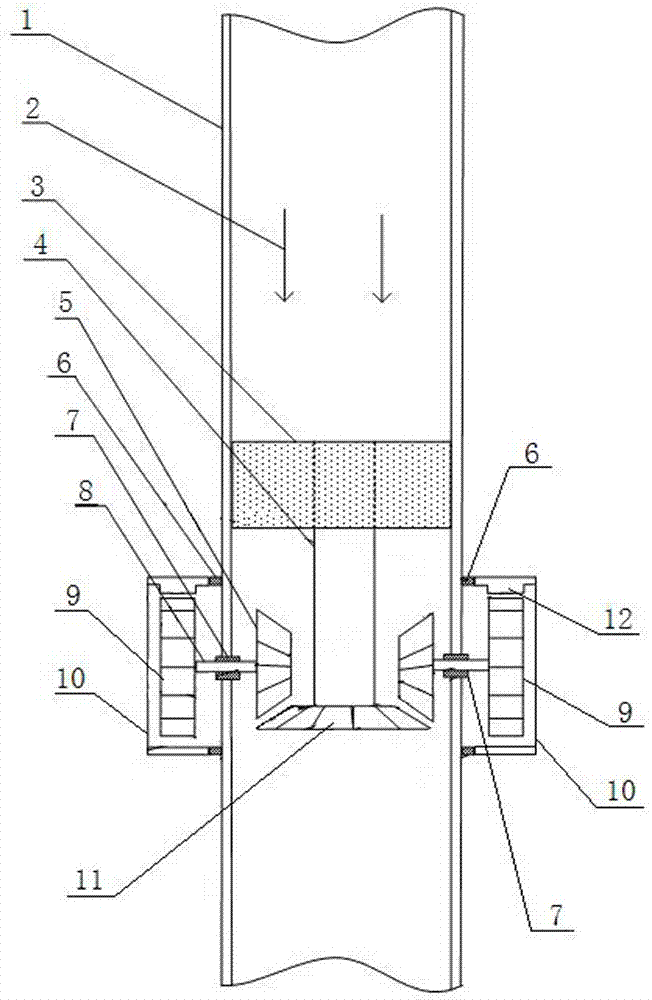

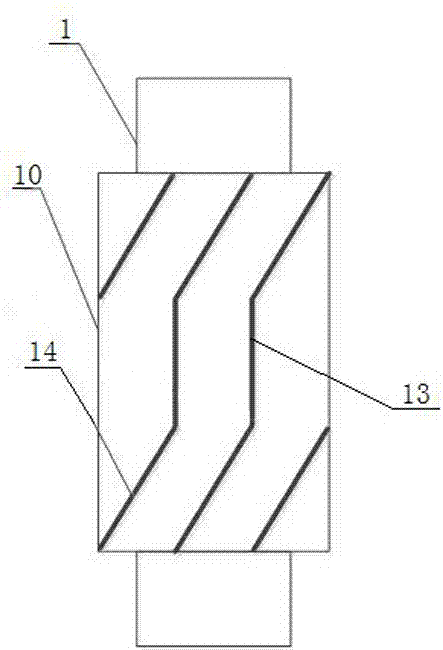

[0022] Such as figure 1 As shown, this turbine-driven debris bed removal device includes a turbine group 3, a transmission shaft 4, a driving bevel gear 11, a linkage bevel gear group, a turbulence generator 10, a turbine group 3, a transmission shaft 4, and a driving bevel gear. The gear 11 and the internal gear 5 of the linkage bevel gear set are all installed inside the drill pipe 1. The linkage bevel gear set is formed by connecting the internal gear 5 and the external gear 9 through the linkage shaft 8, and is fixed on the drill pipe through the linkage shaft 8 1, a sealed bearing 7 is arranged between the linkage shaft 8 and the drill pipe 1, the internal gear 5 is located in the drill pipe 1, and the external gear 9 is located in the turbulence generator 10. The turbine stator is directly fixed on the inner wall of the drill pipe 1, the turbine rotor is connected to the transmission shaft 4, and the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com