Resisting force dodging device for controlling floor heave, and construction method for device

A technology for bottom heaving and anchoring beams, which is applied in the installation of anchor rods, shaft equipment, earthwork drilling and mining, etc. It can solve the problems of large deformation of the bottom drum, achieve large deformation space, save support costs, and increase the overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides a resistance device for controlling the bottom. In order to make the purpose, technical solution and effect of the present invention clearer and clearer, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

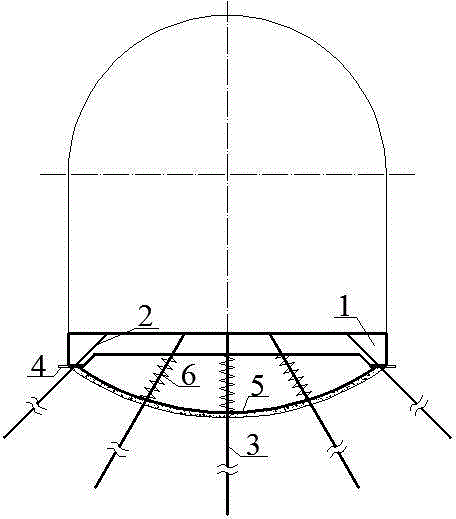

[0025] Such as figure 1 As shown, a yielding device for controlling bottom heaving in the present invention is mainly composed of a sleeper anchor beam 1, a prestressed anchor rod 2, a prestressed anchor cable 3, a sliding assembly 4, an arc-shaped elastic steel belt 5 and a high-strength spring 6 .

[0026] The sleeper anchor beam 1 is a prefabricated reinforced concrete beam, and an anchor channel is reserved on the beam body; the prestressed anchor rod 2 adopts ribbed steel bars, and the anchoring method can be end anchor or full-length anchor; The prestressed anchor cable 3 adopts mining anchor cable.

[0027] The sliding assembly 4 is a flat assemb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com