Filtering and fire inhibiting device for coal mine gas extraction pipeline

A coal mine gas and extraction pipe technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve problems such as flow or accumulation in a certain place, large investment, and large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

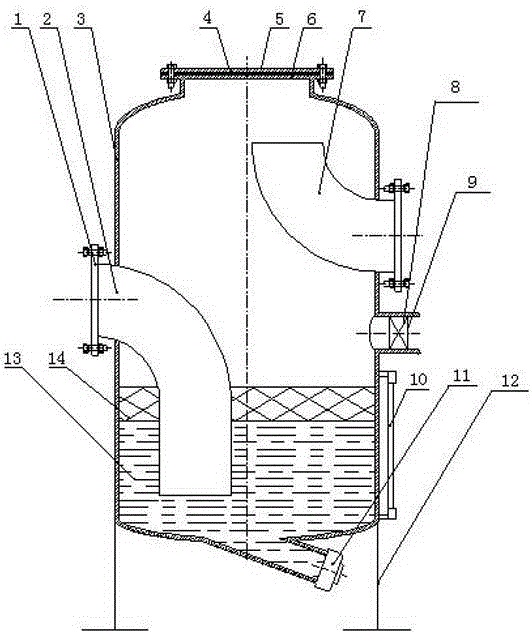

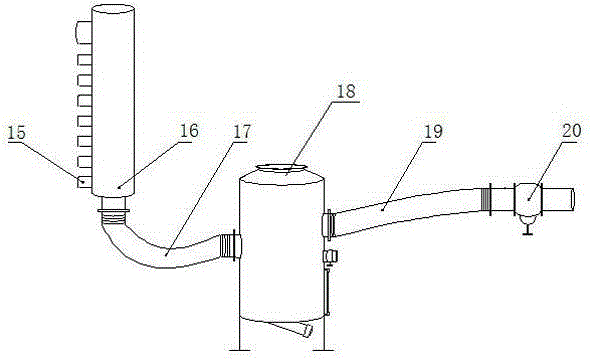

[0019] Such as figure 1 , 2 The shown filter fire suppressing device for coal mine gas extraction pipeline includes a filter fire suppression tank body and a gas conveying assembly installed on the filter fire suppression tank body, a filter medium assembly, and a water volume control slag removal assembly. This structure integrates the original separation structure using different equipment, and solves the problems existing in the original equipment.

[0020] The filter fire suppression tank body is composed of a tank body 3, a loam cake installed on the top of the tank body 3 and a bracket 12 installed on the bottom of the tank body.

[0021] The upper cover is composed of an explosion venting cover 4, an upper cover upper flange 5 and an upper cover lower flange 6 which fix the explosion venting cover by bolts and nut gaskets. The upper cover bolt, the upper cover nut, the upper cover gasket, the upper cover flange 5, the explosion vent cover 4, the upper cover lower flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com